Nitrogen-doped soft carbon-coated silicon-based lithium ion negative electrode material as well as preparation method and application thereof

A technology of negative electrode materials and doped materials, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve problems affecting material consistency, poor particle dispersion, and affecting material cycle performance, etc., to achieve excellent consistency, high The effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

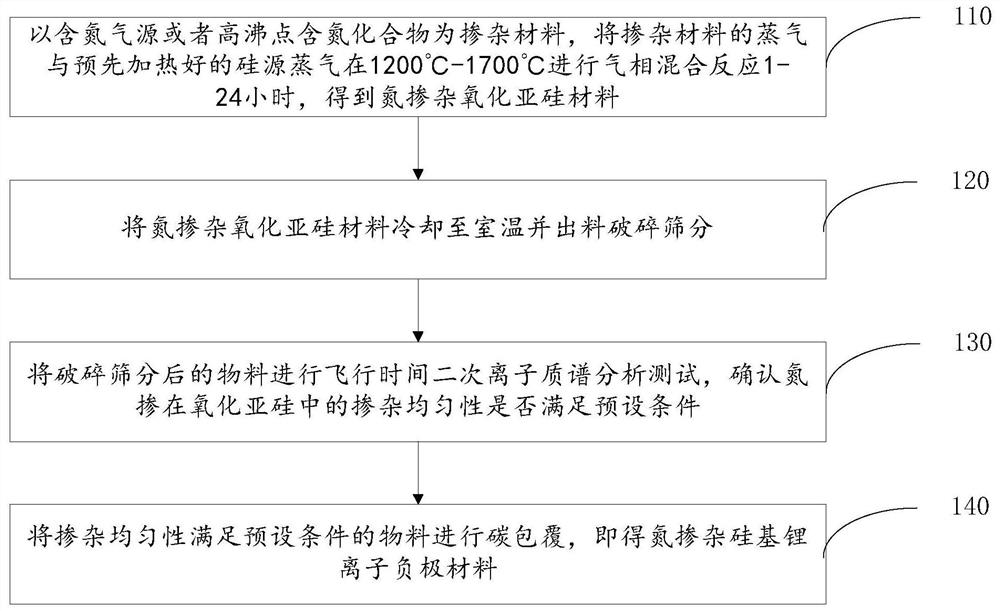

[0029] The preparation method of nitrogen-doped soft carbon coated silicon-based lithium ion negative electrode material of the present invention, its steps are as follows figure 1 shown, including:

[0030] Step 110, using a nitrogen-containing gas source or a high-boiling point nitrogen-containing compound as a doping material, performing a gas-phase mixing reaction between the vapor of the doping material and the pre-heated silicon source vapor at 1200°C-1700°C for 1-24 hours to obtain a nitrogen-doped Hybrid silicon oxide material;

[0031] Wherein, the vapor of the doping material is obtained by heating the doping material to 25°C-800°C.

[0032] In the dopant material, the nitrogen-containing gas source is a nitrogen-containing compound that is gaseous at normal temperature, and may specifically include one or more of nitrogen, ammonia, nitrous oxide or dimethylamine; the high-boiling nitrogen-containing compound is The following is a liquid or solid nitrogen-containin...

Embodiment 1

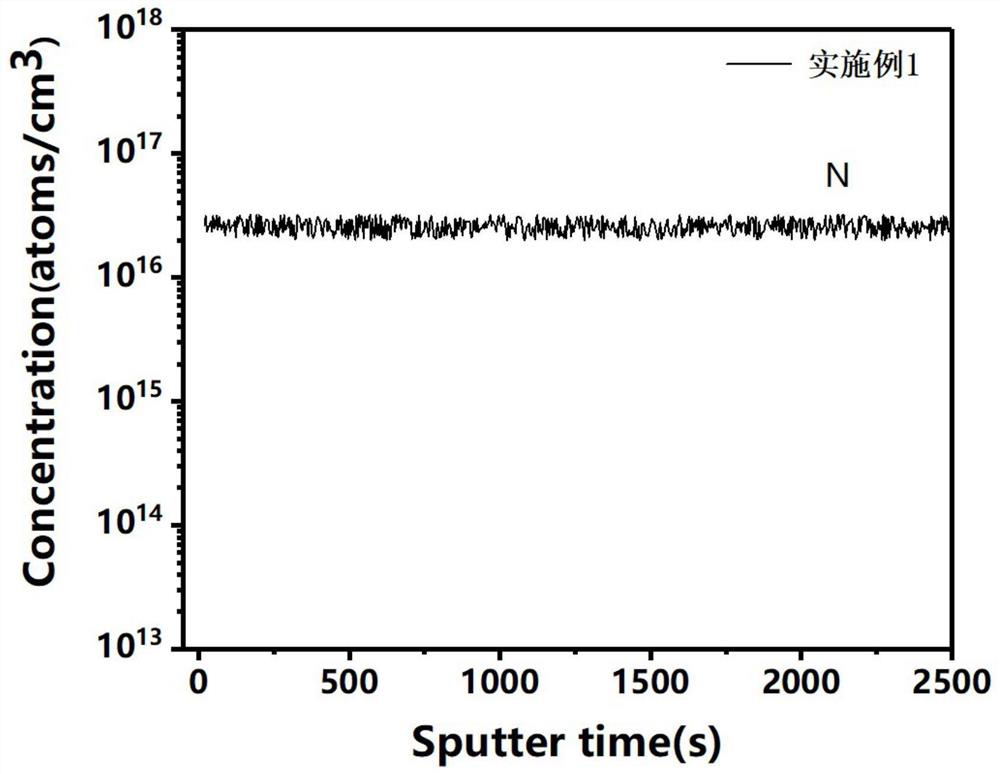

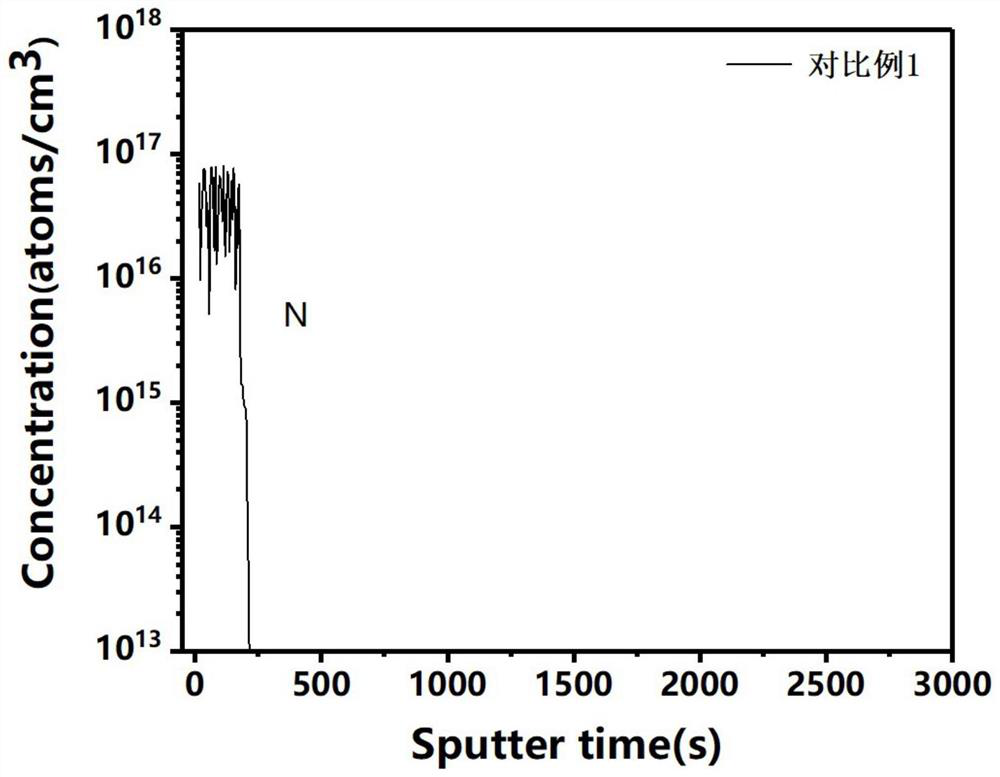

[0045] Put 1.4kg of silicon powder and 3kg of silicon dioxide in a high-temperature reaction furnace and heat it to turn it into steam. At the same time, slowly feed 1.6L (converted mass: 2g) of nitrogen gas under the protection of argon, react at 1400°C for 3 hours, and cool to room temperature. After the material is crushed, it is detected by a time-of-flight secondary ion mass spectrometer (TOF-SIMS). figure 2 The time-of-flight secondary ion mass spectrum of the nitrogen-doped silicon-based lithium-ion battery anode material provided in Example 1 of the present invention will be used later for comparison with the comparative example.

[0046]Put 2kg of the material that passed the test into a rotary furnace, raise the temperature to 1000°C under a protective argon atmosphere, and pass in argon and an organic mixed gas equal to that of argon at a volume ratio of 1:1 for chemical vapor deposition. The gas is a mixed gas of propylene and methane with a volume ratio of 1:1. ...

Embodiment 2

[0050] Put 4.2kg of silicon powder and 9kg of silicon dioxide in a high-temperature reaction furnace and heat it to turn it into steam. At the same time, 23.4L (converted mass is 18g) of ammonia gas is slowly introduced under the protection of argon, and the reaction is carried out at 1200°C for 8 hours. Cool to room temperature. After the material is broken, it is qualified by TOF-SIMS. Put 2kg of the material that passed the test into a rotary furnace, raise the temperature to 850°C under a protective argon atmosphere, and pass in argon and an organic mixed gas equivalent to argon at a volume ratio of 1:1 for chemical vapor deposition. The gas is a mixed gas of propylene and methane with a volume ratio of 2:3. After keeping the temperature for 3 hours and turning off the organic gas source to cool down, a uniform nitrogen-doped soft carbon-coated silicon-based lithium-ion battery negative electrode material is obtained. The nitrogen content in the obtained negative electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com