Solar cell and preparation method thereof

A solar cell and electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high price and limit the wide application of silicon cells, and achieve the effects of inhibiting charge recombination, inhibiting ion migration, and improving solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

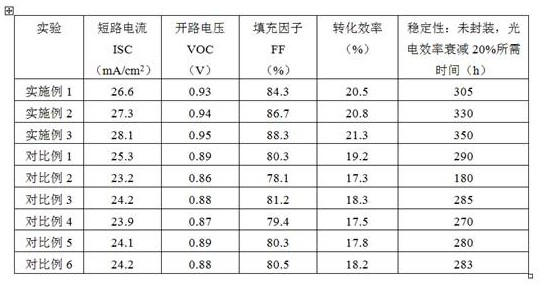

Examples

Embodiment 1

[0028] S1: Clean the conductive substrate; use detergent, deionized water, acetone, absolute ethanol, and isopropanol to ultrasonically clean the conductive substrate for 20 minutes, and then dry it in a vacuum oven at 75°C; then use N 2 After drying, it was treated with an ultraviolet ozone cleaning machine for 10 minutes;

[0029]S2: Preparation of hole transport layer: Mix 1ml of 4-tert-butylpyridine, 2ml of Li-TFSI and 100ml of chlorobenzene to obtain mixture A, then add 2g of Spiro-OMeTAD; stir until completely dissolved to obtain Spiro-OMeTAD solution , ultrasonically spin coating the surface of the conductive substrate obtained in step S1, annealing at a temperature of 80° C. for 5 minutes, and naturally cooling to room temperature to form a Spiro-OMeTAD hole transport layer;

[0030] S3: Preparation of perovskite absorbing layer: mix 6g of methylamine iodine and 5g of PbI 2 Dissolve in 40ml of methylamine acetate (MAAc) and stir well; raise the temperature to 40°C, ad...

Embodiment 2

[0035] S1: Clean the conductive substrate; use detergent, deionized water, acetone, absolute ethanol, and isopropanol to ultrasonically clean the conductive substrate for 30 minutes, and then dry it in a vacuum oven at 85°C; then use N 2 After drying, it was treated with an ultraviolet ozone cleaning machine for 15 minutes;

[0036] S2: Preparation of hole transport layer: Mix 3ml of 4-tert-butylpyridine, 5ml of Li-TFSI and 100ml of chlorobenzene to obtain mixture A, then add 1.5g of Spiro-OMeTAD; stir until completely dissolved to obtain Spiro-OMeTAD Solution, ultrasonically spin-coated on the surface of the conductive substrate obtained in step S1, annealed at a temperature of 100° C. for 10 minutes, and naturally cooled to room temperature to form a Spiro-OMeTAD hole transport layer;

[0037] S3: Preparation of perovskite absorbing layer: mix 10g of methylamine iodine and 15g of PbI 2 Dissolve in 60ml of methylamine acetate (MAAc) and stir well; raise the temperature to 60...

Embodiment 3

[0042] S1: Clean the conductive substrate; use detergent, deionized water, acetone, absolute ethanol, and isopropanol to ultrasonically clean the conductive substrate for 25 minutes, and then dry it in a vacuum oven at 80°C; then use N 2 After drying, it was treated with an ultraviolet ozone cleaning machine for 12 minutes;

[0043] S2: Preparation of the hole transport layer: Mix 2ml of 4-tert-butylpyridine, 3ml of Li-TFSI and 100ml of chlorobenzene to obtain a mixture A, then add 1.6g of Spiro-OMeTAD, stir until completely dissolved to obtain Spiro- The OMeTAD solution is ultrasonically spin-coated on the surface of the conductive substrate obtained in step S1, annealed at a temperature of 90° C. for 7 minutes, and naturally cooled to room temperature to form a Spiro-OMeTAD hole transport layer;

[0044] S3: Preparation of perovskite absorbing layer: mix 8g of methylamine iodide and 12g of PbI 2 Dissolve in 55ml of methylamine acetate (MAAc) and stir well; raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com