Antibacterial bionic coating as well as preparation method and application thereof

A technology of coatings and coating materials, applied in coatings, pharmaceutical formulations, catheters, etc., can solve problems such as the decline in the content of antibacterial active components, immune reactions and inflammation, and affect the effective period of antibacterial, and achieve short response time and good antibacterial properties The effect of the property and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Described zwitterionic polymer PVAm-PC is specifically prepared by the following method:

[0045] At 55°C, the methanol solution of aldylated glycerophosphorylcholine (PCGA) was added dropwise to the methanol solution of polyvinylamine (PVAm), wherein the molar ratio of PCGA to PVAm was 1:0.25, and the reaction was stirred for 24 hours to obtain reaction mixture. Sodium cyanoborohydride (NaBH 3 CN) methanol solution was added dropwise to the reaction mixture cooled to 0°C, where NaBH 3 The molar ratio of CN to PCGA was 1:1, heated to room temperature and stirred for 24 h, dialyzed with deionized water (molecular weight cut-off 500) for 3 days, and freeze-dried to obtain phosphorylcholined polyvinylamine (PVAm-PC). where y / (x+y)=0.5.

[0046] The zwitterionic polymer CS-PC described in the embodiment has following molecular structure:

[0047]

[0048] Wherein, x=200, y=800, n=2000.

[0049] The CS-PC was prepared by the following method: at 60°C, a deionized aqueo...

Embodiment 1

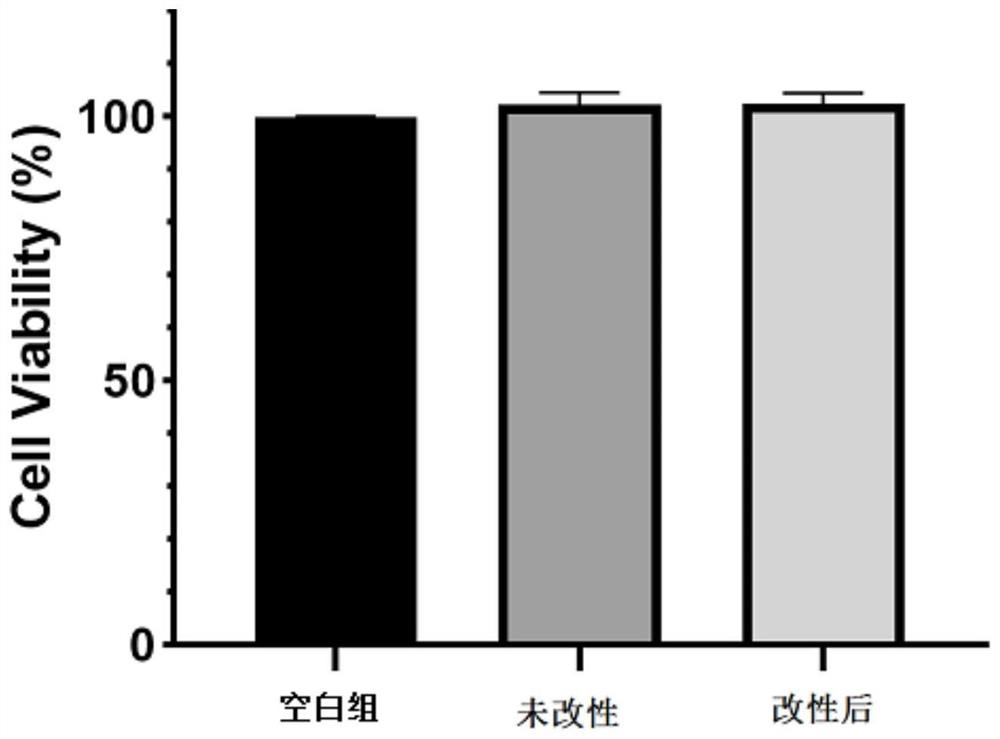

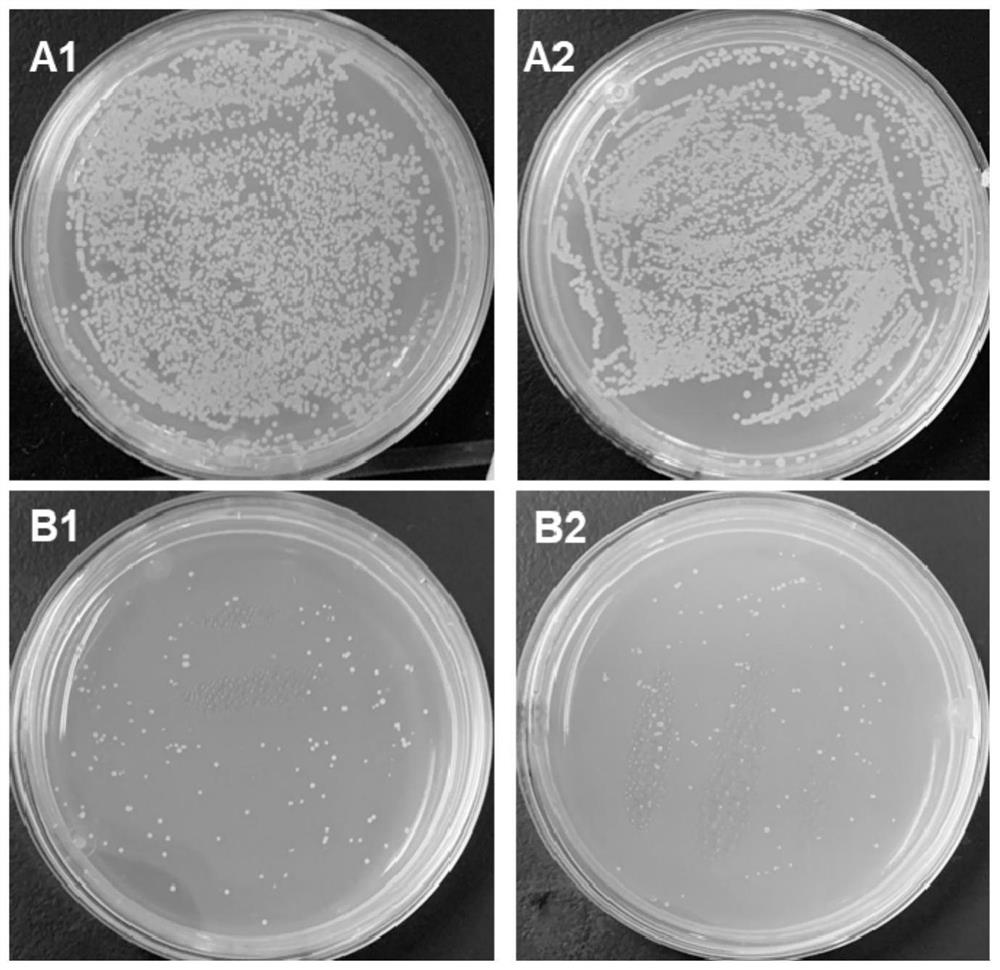

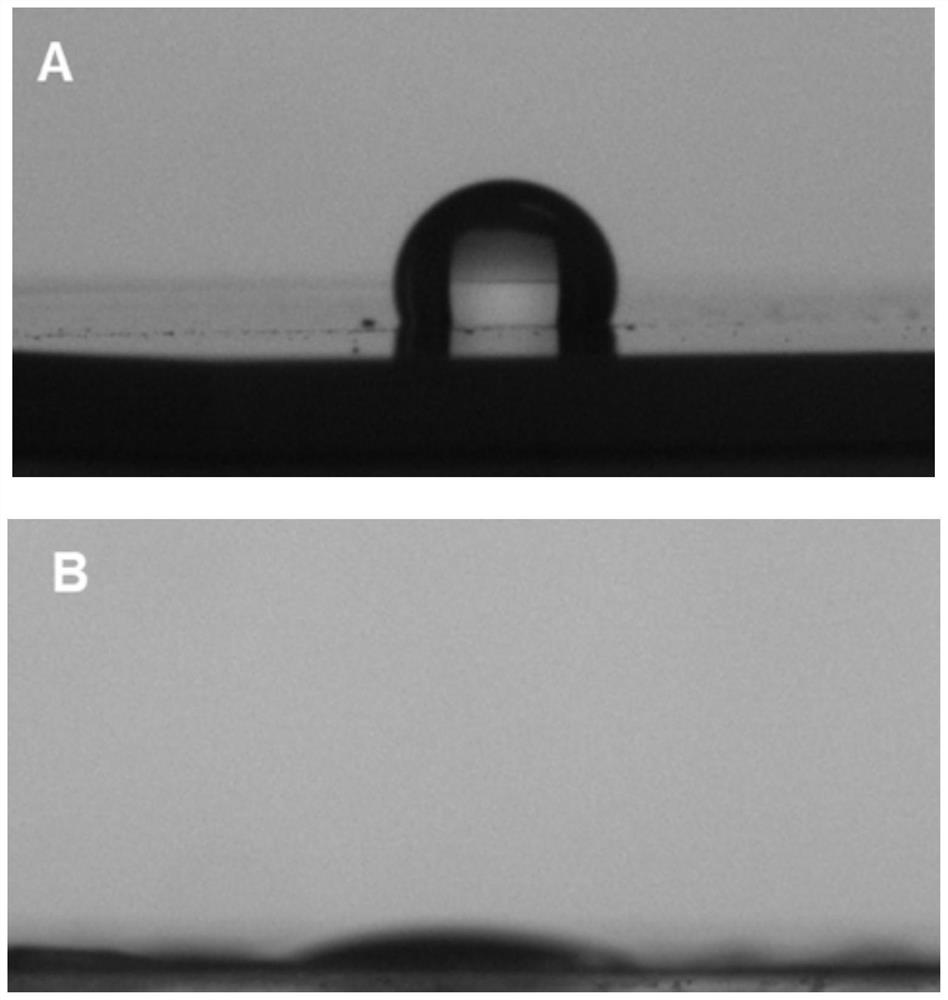

[0050] Example 1 Preparation of polyphenol / zinc-zwitterionic polymer coating on the surface of medical catheter

[0051] (1) Surface activation of medical catheters

[0052] Ultrasonic cleaning of medical catheters with a diameter of 1 cm and a height of 3 cm in acetone, ethanol, and deionized water for 10 minutes, and preparing 3 mol / L sodium hydroxide solution, soaking the cleaned medical catheters in it, soaking at 60 ° C for 2 hours, and then ultrasonic cleaning 10min.

[0053] (2) Preparation of polyphenol / zinc coating

[0054] 40mg of epigallocatechin gallate (EGCG), 20mg of zinc acetate and 20mg of ammonium persulfate were added to 40mL of pH in the PBS buffer solution of 8.0, stirred evenly to obtain a mixed solution; step (1) The treated medical catheter and the mixed solution were added to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and reacted at 80°C for 5 hours. After the reaction was completed, it was washed with deionized water and dried in v...

Embodiment 2

[0057] The preparation of embodiment 2 polyurethane sponge dressing surface polyphenol / zinc-zwitterionic polymer coating

[0058] (1) Clean the polyurethane sponge and activate the surface

[0059] Ultrasonic cleaning of 1×1×2 cm polyurethane sponges in deionized water for 15 minutes, preparation of 2 mol / L sodium hydroxide solution, soaking the cleaned polyurethane sponges at 60°C for 1 hour, and then ultrasonic cleaning for 20 minutes.

[0060] (2) Preparation of polyphenol / zinc coating

[0061] 40mg of epigallocatechin gallate (EGCG), 20mg of zinc acetate and 20mg of ammonium persulfate were added to 40mL of pH in the PBS buffer solution of 8.0, stirred evenly to obtain a mixed solution; step (1) The treated polyurethane sponge and the mixed solution were added together into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and reacted at 70°C for 2 hours. After the reaction, it was washed with deionized water and dried in vacuum to obtain polyphenol / zinc coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com