Multivalent copper nano-material, preparation method thereof and application of multivalent copper nano-material as electrocatalyst in carbon capture technology

A copper nanometer and multivalent state technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that hinder the industrialization process of resource utilization, the selectivity of reduction products is not high, and the range of catalysts is limited, so as to achieve good conversion effect, Suitable for popularization and application, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides the activation treatment steps of activated carbon, specifically: select Valcan XC-72 Carbon as the carrier, place the activated carbon in a suitable glass reaction vessel, and add 50wt% HNO 3 The solution was heated and stirred at 90° C. for 3 hours, then washed with water, dried, and passed through a 200-mesh sieve for later use. The purpose is to change the internal structure of the carbonized material, expand the specific surface area, increase the specific surface area of the activated carbon material and modify the surface structure, and finally improve the adsorption performance of the activated carbon material.

Embodiment 2

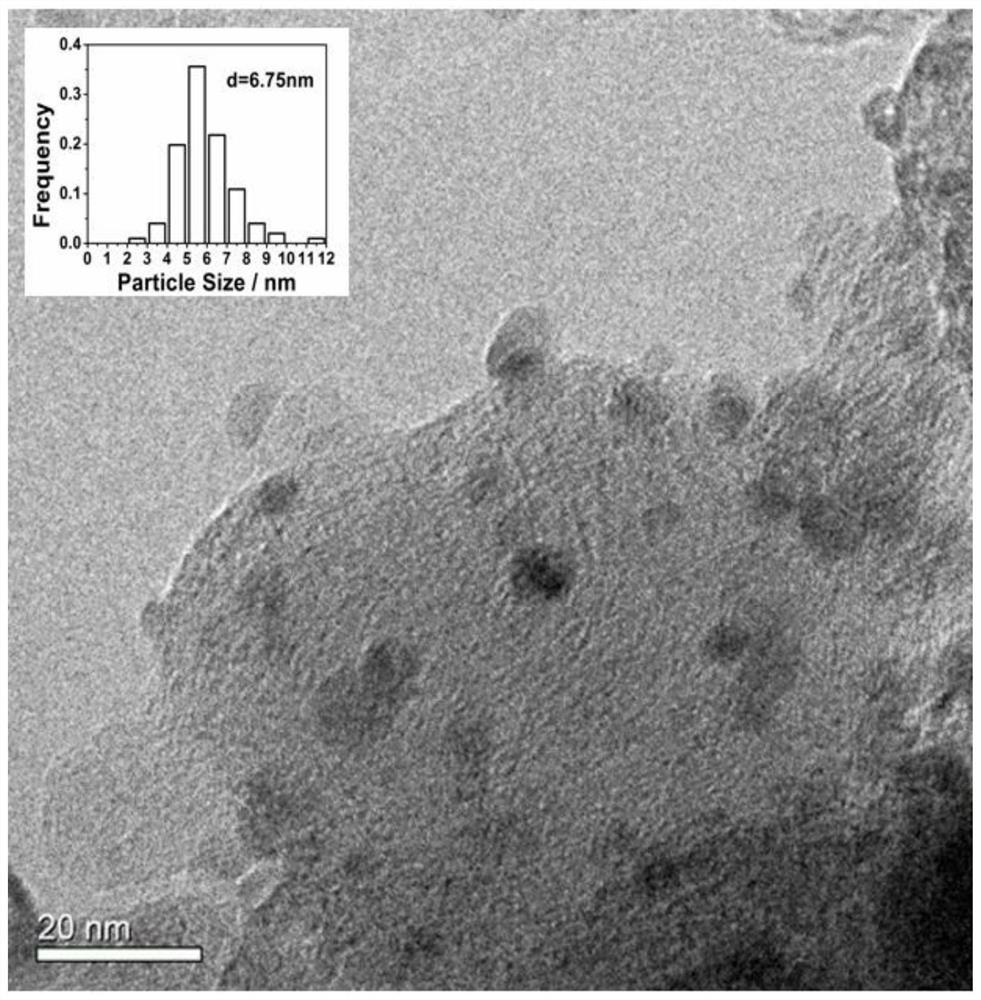

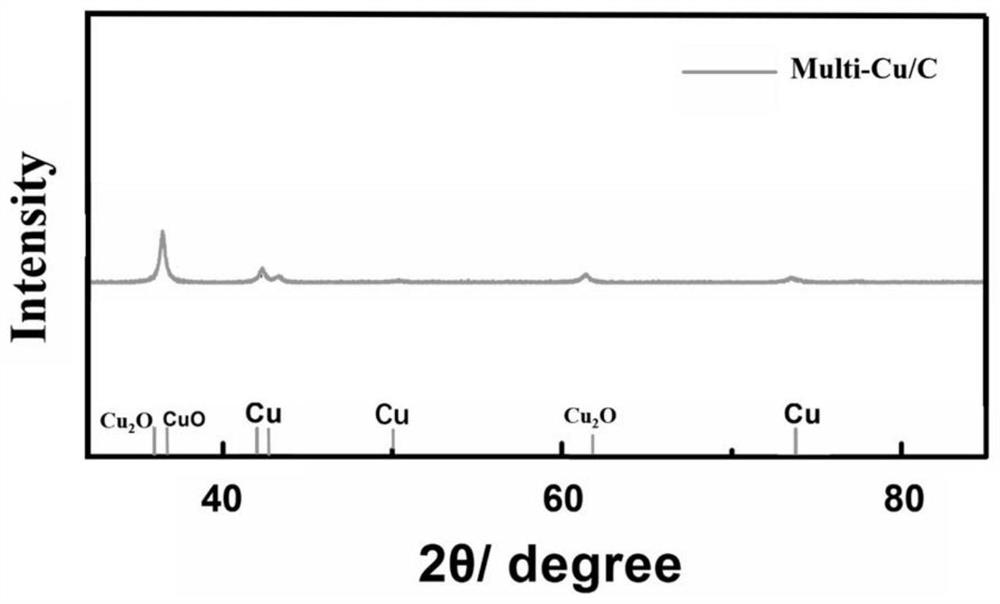

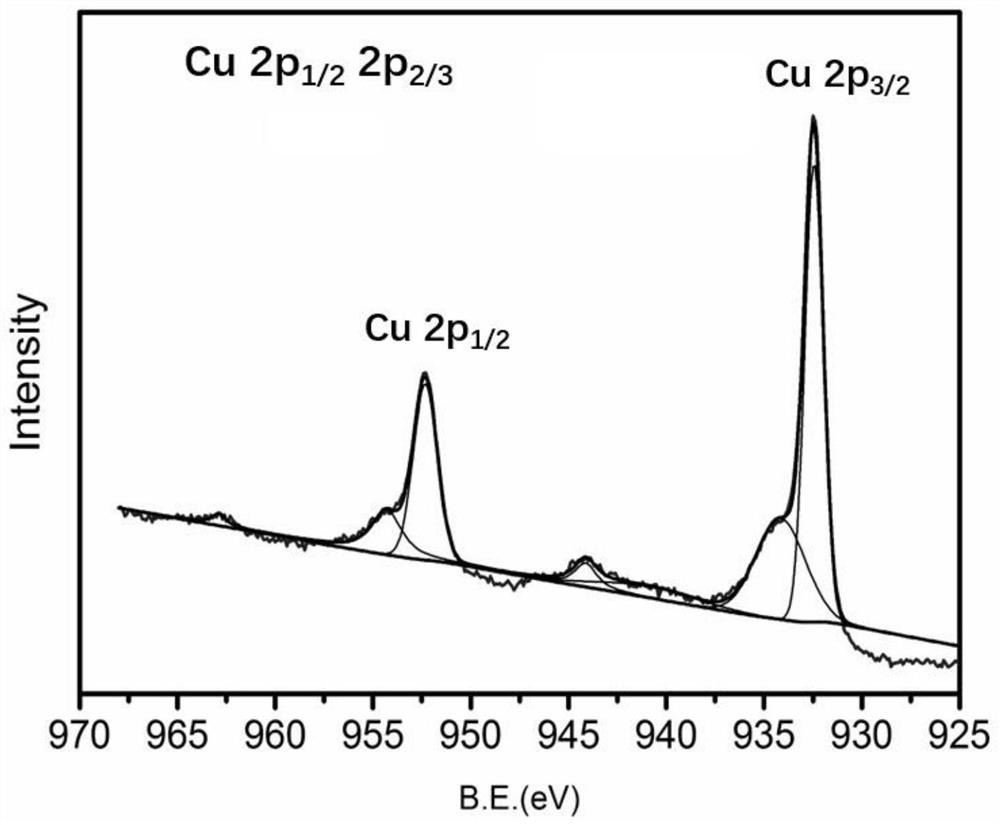

[0038] This embodiment provides a method for preparing multivalent copper nanomaterials, using sodium borohydride reduction, comprising the following steps:

[0039] Step S1: Take a dilute copper chloride solution with a molar concentration of 1mol / L, and add a complexing agent ethylenediaminetetraacetic acid (EDTA) with a concentration of 1mol / L to complex CuCl 2 Solution, forming the complex of copper salt precursor;

[0040] Step S2: Add the activated carbon pre-treated in Example 1 to the complex obtained in the step S1, the carbon load can be 10%, add 10mL high-purity water, mix well, then add 5mL stabilizer ammonia water and mix well;

[0041] Step S3: Add 10 mL of sodium borohydride solution dropwise to the product obtained in step S2 using a peristaltic pump or a flow injector. The ratio of the concentration of the sodium borohydride solution to the concentration of the reactants is 1:10, and the reduction is carried out in an ice-water bath React for 1 hour. After th...

Embodiment 3

[0044] The polyvalent copper nanomaterial prepared in Example 2 is used for electrocatalysis of CO 2 . Figure 5 It is a schematic structural diagram of the H-type electrolytic cell used in Example 3 of the present application. see Figure 5 , this embodiment adopts the laboratory self-constructed CO 2 Captured reaction system device, H-type electrolytic cell. The H-type electrolytic cell includes an anode chamber and a cathode chamber, and the tops of the anode chamber and the cathode chamber are provided with polytetrafluoroethylene covers with gas inlets and gas outlets to ensure airtightness. The anode chamber and the cathode chamber are separated by a proton exchange membrane, ions can pass through freely, but molecules cannot pass through, and KHCO is added to both the anode chamber and the cathode chamber 3 Electrolyte solution, the working electrode and the reference electrode are placed in the cathode chamber, the counter electrode is placed in the anode chamber, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com