Preparation method of composite structure oxygen reduction electrocatalyst for fuel cell cathode

A fuel cell cathode and composite structure technology, applied to battery electrodes, structural parts, circuits, etc., can solve the problems of high price, poor stability, and low exchange current density, and achieve simple process operation, low production cost, and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

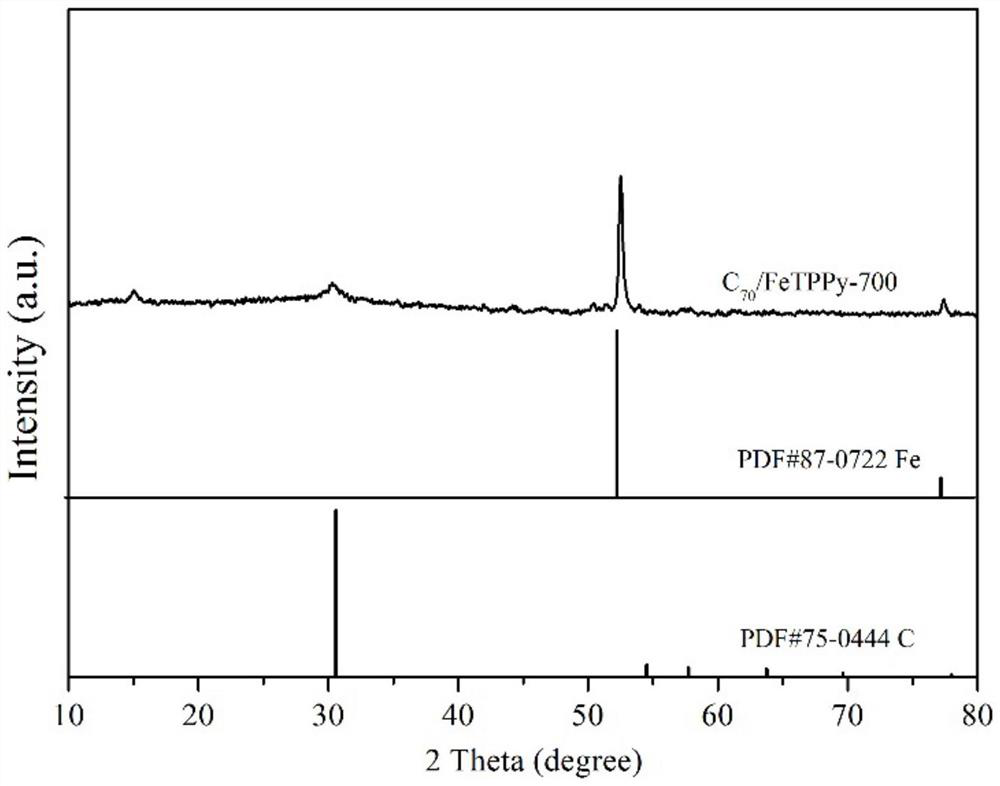

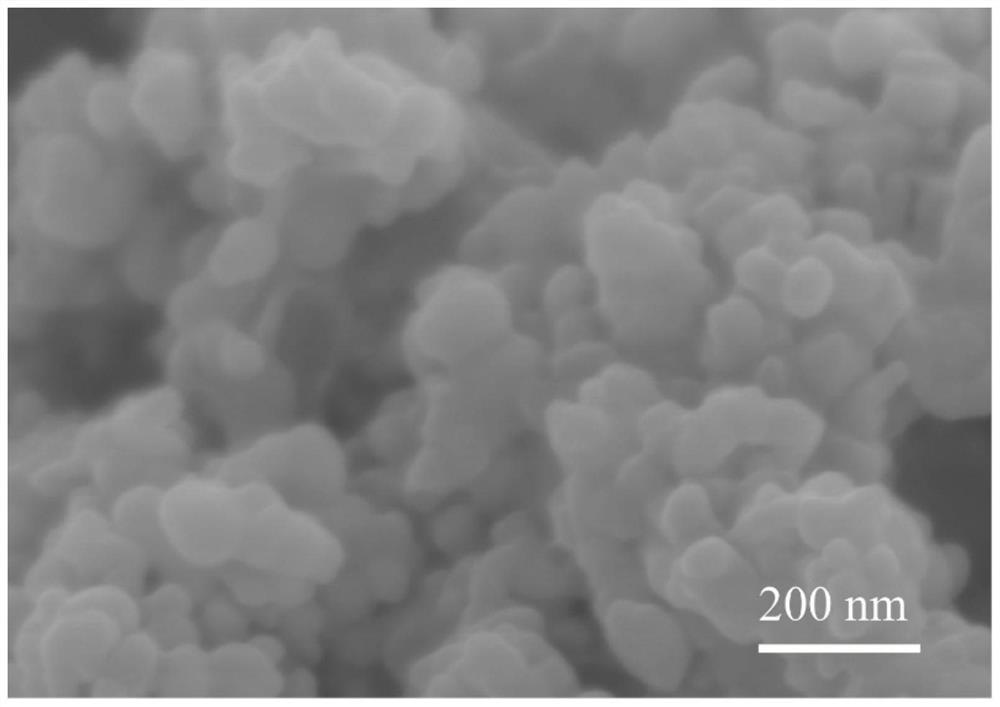

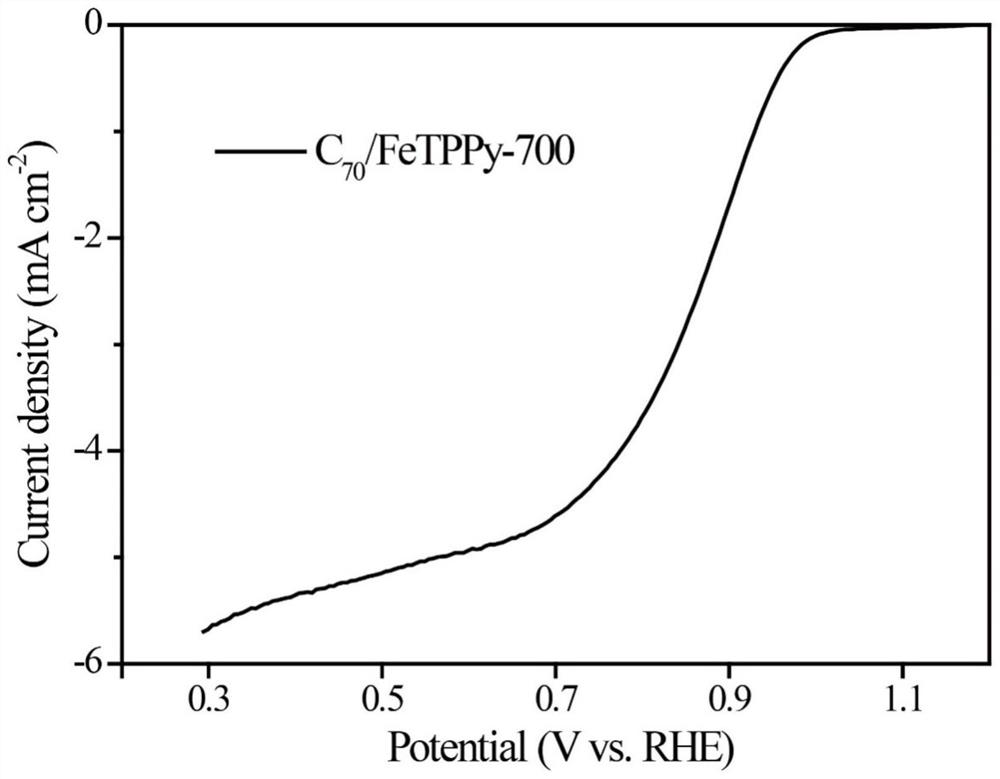

Embodiment 1

[0026] 1) Preparation of metalloporphyrin: Take 1 mole of tetrapyridyl porphyrin, 2 moles of ferric chloride hexahydrate and 100 mL of DMF solvent in a three-necked flask under nitrogen atmosphere, magnetically stir evenly, heat up to 120 ° C, condense and reflux After 9 hours, cool down to room temperature naturally after the reaction, transfer the reacted solution to a beaker, add ultrapure water to precipitate the metalloporphyrin, then remove the solution by rotary evaporation, and place the residue in a petri dish to freeze for 8 hours. Transfer to dry 10h in freeze drier to get tetrapyridyl iron porphyrin;

[0027] 2) Preparation of composite structure: take fullerene C at a mass ratio of 1:1 70 and tetrapyridyl iron porphyrin, first prepare 2 mg / mL fullerene toluene solution, ultrasonically disperse for 10 minutes and then filter, then add tetrapyridyl iron porphyrin and ultrasonically disperse for 15 minutes to obtain a mixed solution;

[0028] 3) The above-mentioned ...

Embodiment 2

[0035] 1) Preparation of metalloporphyrin: Take 1 mole of tetrapyridyl porphyrin, 5 moles of ferric chloride hexahydrate and 120 mL of DMF solvent in a three-necked flask under nitrogen atmosphere, magnetically stir evenly, heat up to 140 ° C, condense and reflux 8h, after the reaction is finished, cool naturally to room temperature, transfer the reacted solution to a beaker, add ultrapure water to precipitate the metalloporphyrin, then use rotary evaporation to remove the solution, and place the residue in a petri dish to freeze for 12 hours. Transfer to dry 24h in freeze drier to obtain tetrapyridyl iron porphyrin;

[0036] 2) Preparation of composite structure: take fullerene C at a mass ratio of 1:2 70 and tetrapyridyl iron porphyrin, first prepare 2.5 mg / mL fullerene toluene solution, ultrasonically disperse for 15 minutes and then filter, then add tetrapyridyl iron porphyrin and ultrasonically disperse for 15 minutes to obtain a mixed solution;

[0037] 3) The above-men...

Embodiment 3

[0041] 1) Preparation of metalloporphyrin: Take 1 mole of tetrapyridyl porphyrin, 6 moles of ferric chloride hexahydrate and 150 mL of DMF solvent in a three-necked flask, stir evenly under a nitrogen atmosphere, heat up to 160 ° C, condense and reflux 7h, after the reaction is finished, cool naturally to room temperature, transfer the reacted solution to a beaker, add ultrapure water to precipitate the metalloporphyrin, then use rotary evaporation to remove the solution, and place the residue in a petri dish to freeze for 10 hours to obtain a solid Transfer to dry 24h in freeze drier to obtain tetrapyridyl iron porphyrin;

[0042] 2) Preparation of composite structure: take fullerene C at a mass ratio of 1:3 70 and tetrapyridyl iron porphyrin, first prepare 3 mg / mL fullerene toluene solution, ultrasonically disperse for 30 minutes and then filter, then add tetrapyridyl iron porphyrin and ultrasonically disperse for 10 minutes to obtain a mixed solution;

[0043] 3) The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com