Water-based flame-retardant energy-saving anticorrosive coating and preparation method thereof

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor thermal insulation and energy saving, poor thermal insulation performance, poor reflection effect, etc., and achieve good water resistance. , Improve the strength, the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A kind of preparation method of water-based flame-retardant energy-saving anticorrosion coating of the present invention, concrete operation steps are as follows:

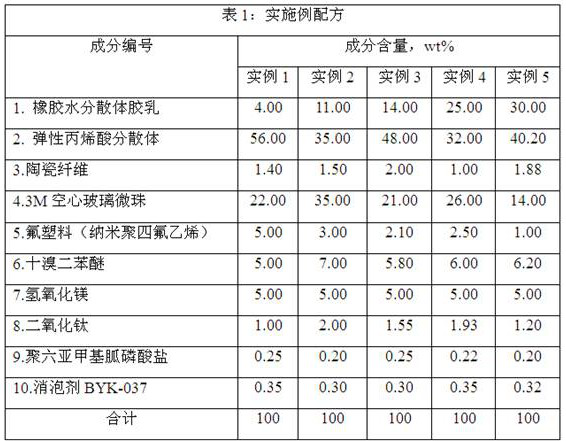

[0061] 1) Weigh 4.00-30.00 wt% rubber aqueous dispersion latex, 32.00-56.00 wt% elastic acrylic dispersion, 0.30-0.35 wt% defoamer, 0.20-0.25 wt% polyhexamethylene Add guanidine phosphate into the dispersion tank and disperse at low speed for 5-10 minutes to obtain a homogeneous mixture I;

[0062] 2) Weigh 1.00-5.00 wt% of fluoroplastics, 5.00-7.00 wt% of decabromodiphenyl ether, 5.00 wt% of magnesium hydroxide, 1.00-2.00 wt% of titanium dioxide, 1.00-2.00 wt% of Ceramic fiber, under low-speed stirring, add to the mixed solution I in turn, and then disperse at a high speed for 10-15 minutes, until the mixture is evenly mixed, and the mixture II is obtained;

[0063] 3) Add 14.00-35.00 wt% of 3M hollow glass microsphere mixture (the weight ratio of 600 mesh glass microspheres and glass microspheres with a p...

Embodiment 1

[0067] 1) Weigh 4.00 parts of rubber water dispersion latex, 56.00 parts of elastic acrylic dispersion, 0.35 parts of defoamer BYK-0340, and 0.25 parts of polyhexamethylene guanidine phosphate into the dispersion tank, and disperse at a low speed of 300-500 r / min 5-10 minutes to obtain a homogeneous mixture I;

[0068] 2) Under stirring at a low speed of 300-500 r / min, add 5.00 parts of fluoroplastic (nano polytetrafluoroethylene), 5.00 parts of decabromodiphenyl ether, 5.00 parts of magnesium hydroxide, 1.00 parts of titanium dioxide, and 1.40 parts of ceramic fiber to mix In liquid I, disperse at a high speed of 1000-1500 r / min for 10-15 minutes, until the mixture is uniform, and the mixture II is obtained;

[0069] 3) Under the condition of stirring and dispersing at a low speed of 300-500 r / min, add 22.00 parts of the hollow glass microsphere mixture (the weight ratio of 600 mesh glass microspheres to glass microspheres with a particle size of 20-120 μm is 3:2) into the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com