Preparation method of essential oil microcapsule yarns

A technology of microcapsules and yarns, applied in the field of yarns, can solve the problems of unsatisfactory sustained-release effect of essential oils, poor secondary processing performance and mechanical properties of fiber webs, slow sustained-release effect, etc., and achieve good skin light resistance Aging resistance, satisfying wearing comfort, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An essential oil microcapsule is a lavender microcapsule made by a saturated aqueous solution method; wherein, the volume-to-mass ratio of lavender essential oil to β-cyclodextrin is 0.12ml:1g; the inclusion temperature in the saturated aqueous solution method is 39.3°C, and the inclusion Combined time is 1.48h.

[0053] The prepared lavender microcapsule is to take β-cyclodextrin as the wall material, and the capsule structure with lavender essential oil as the core material; and the oil content is 120mg / g; (oil content=essential oil (mg) / microcapsule ( g), the oil content of the microcapsules is tested by liquid chromatography-mass spectrometry)

[0054] The prepared lavender microcapsules were stored indoors at a constant temperature of 25°C, and the content of essential oil in the lavender microcapsules was continuously tested for 28 days. It was found that after 28 days, the release rate of essential oil in the microcapsules was 30%, which has a long-lasting fragra...

Embodiment 2

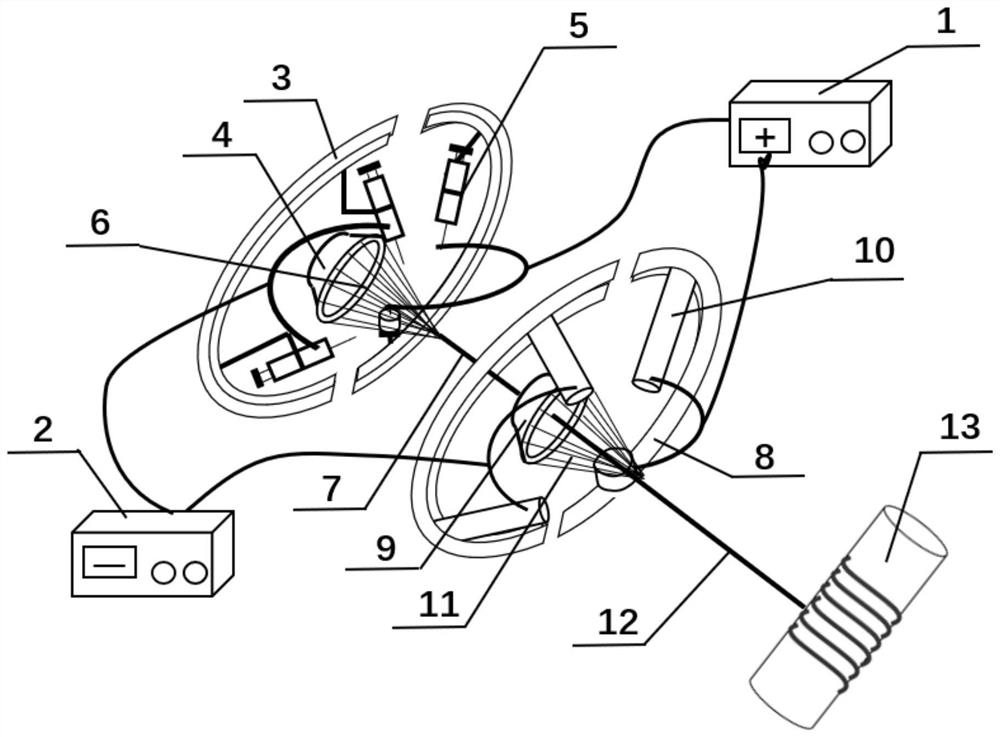

[0056] An electrospinning device, such as figure 1 As shown, it includes a high-voltage electrostatic positive electrode terminal 1, a high-voltage electrostatic negative electrode terminal 2, and a positive and negative conjugate needle assembly, a positive and negative conjugate nozzle assembly, and a winding roller 13 arranged in sequence along one direction.

[0057] The positive and negative conjugate needle assembly consists of a bracket I3, a rotating metal bell mouth A4 and 4 needle injection pumps 5; the 4 needle injection pumps 5 are all installed on the bracket I3 and the 4 needle injection pumps are divided into positions symmetrical Two sets of needle injection pumps, one of which is connected to the high-voltage electrostatic positive terminal, and the other group is connected to the high-voltage electrostatic negative terminal; the spinnerets of the four needle injection pumps 5 are all located on the same plane a, and each needle injection pump 5 The distance b...

Embodiment 3

[0061] A preparation method of essential oil microcapsule yarn, comprising the steps of:

[0062] (1) Configure the spinning solution: blend the polymer and the solvent, stir on a constant temperature magnetic stirrer, set the temperature at 60°C, and rotate at 600r / min, and stir for about 24 hours until the polymer is completely dissolved Then, at 40°C, add essential oil microcapsules (prepared in Example 1) and continue magnetic stirring until the microcapsules are uniformly dispersed (stirring for half an hour to achieve uniform dispersion) to obtain an electrospinning solution;

[0063] Spinning solution I: the polymer is polyacrylonitrile powder (PAN, relative molecular mass 75000), the solvent is N,N-dimethylformamide (DMF), and the mass concentration of the polymer is 8%, The mass ratio of microcapsules to polymers is 1:1;

[0064] Spinning solution II: the polymer is polyacrylonitrile powder (PAN, relative molecular mass 75000), the solvent is N,N-dimethylformamide (D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com