Method for recycling graphite from lithium battery negative electrode carbon powder and preparation method of graphene oxide

A lithium battery and graphene technology, applied in battery recycling, carbon compounds, recycling technology, etc., can solve the problems of organic and inorganic pollutant types, complex occurrence and removal mechanisms, etc., to improve the efficiency of chlorination conversion and improve water solubility Sexuality and decentralization, the effect of large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

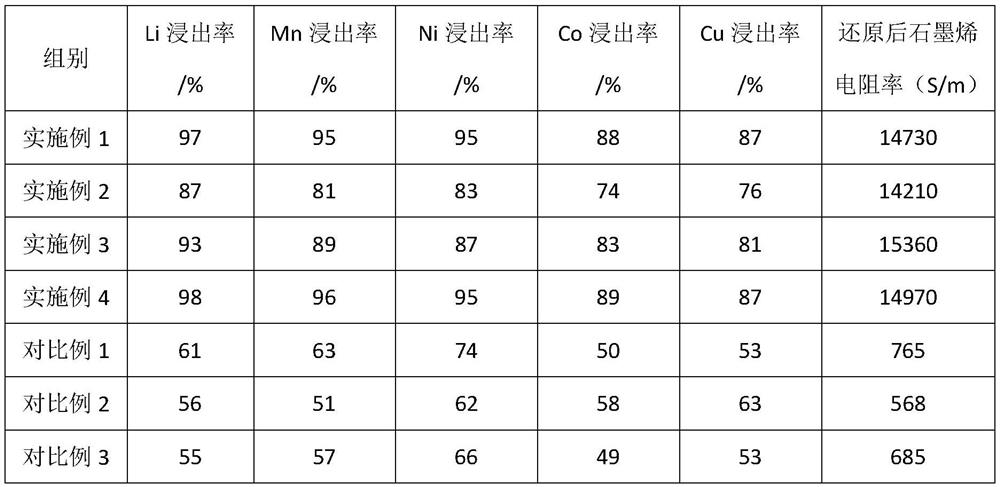

Examples

Embodiment 1

[0041] A method for reclaiming graphite from lithium battery negative electrode carbon powder and preparing graphene oxide from the recovered graphite as a raw material, the specific steps are:

[0042] (1) Add 3g of lithium battery negative electrode material carbon powder to the ball mill, control the speed at 380r / min, and ball mill for 60min.

[0043] (2) Fully grind 9 g of ammonium chloride and 3 g of negative electrode material carbon powder.

[0044](3) Put the ground mixture in a tube furnace, heat up to 300° C. at a heating rate of 5° C. / min under an argon atmosphere, and then bake it for 30 minutes.

[0045] (4) After roasting, take out the carbon powder and put it into a 250mL beaker, add 100mL of deionized water, control the temperature at 40°C, insert the ultrasonic vibrating rod into the solution, turn on the ultrasonic vibrating rod, control the power at 150W, and the ultrasonic time for 1h.

[0046] (5) After the reaction, the leaching liquid and the carbon p...

Embodiment 2

[0055] A method for reclaiming graphite from lithium battery negative electrode carbon powder and a method for preparing graphene oxide from the reclaimed graphite, the specific steps are:

[0056] (1) Add 3g of lithium battery negative electrode material carbon powder to the ball mill, control the speed at 300r / min, and ball mill for 90min.

[0057] (2) Fully grind 3g of ammonium chloride and 3g of negative electrode material carbon powder.

[0058] (3) Put the ground mixture in a tube furnace, heat up to 380° C. at a heating rate of 2° C. / min under an argon atmosphere, and then bake it for 30 minutes.

[0059] (4) After roasting, take out the carbon powder and put it into a 250mL beaker, add 100mL of deionized water, control the temperature at 50°C, insert the ultrasonic vibrating rod into the solution, turn on the ultrasonic vibrating rod, control the power at 200W, and the ultrasonic time It is 1.5h.

[0060] (5) After the reaction, the leaching liquid and the carbon pow...

Embodiment 3

[0069] A method for reclaiming graphite from lithium battery negative electrode carbon powder and a method for preparing graphene oxide from the reclaimed graphite, the specific steps are:

[0070] (1) Add 3g of lithium battery negative electrode material carbon powder to the ball mill, control the speed at 450r / min, and ball mill for 45min.

[0071] (2) Fully grind 6g of ammonium chloride and 3g of negative electrode material carbon powder.

[0072] (3) Put the ground mixture in a tube furnace, heat up to 450° C. at a heating rate of 8° C. / min under an argon atmosphere, and then bake it for 30 minutes.

[0073] (4) After roasting, take out the carbon powder and put it into a 250mL beaker, add 100mL of deionized water, control the temperature at 60°C, insert the ultrasonic vibrating rod into the solution, turn on the ultrasonic vibrating rod, control the power at 250W, and the ultrasonic time for 2h.

[0074] (5) After the reaction, the leaching liquid and the carbon powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com