Light-cured film dispersing device and polymer microcapsule preparation method

A light-curing and film-dispersing technology, used in microcapsule preparations, botanical equipment and methods, microsphere preparation, etc., can solve the problems of slow formation and failure of the wall layer, and achieve a wide range of applications, easy equipment operation, and fast curing. and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

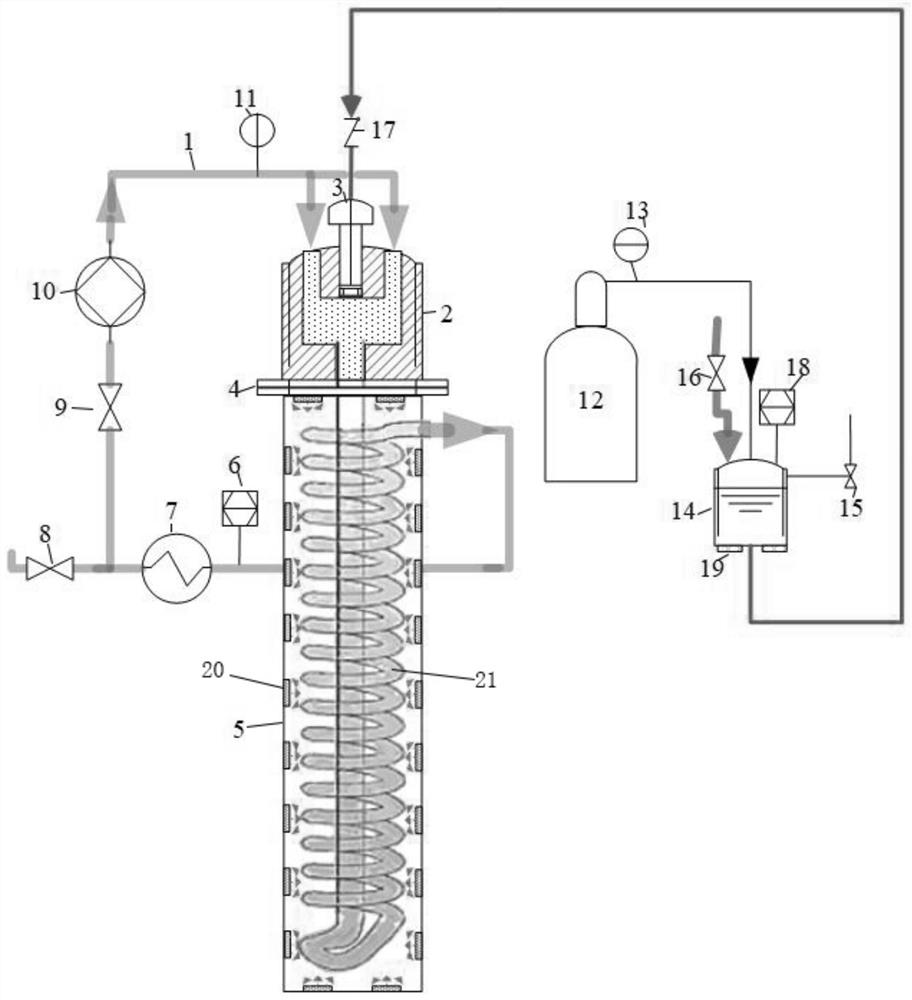

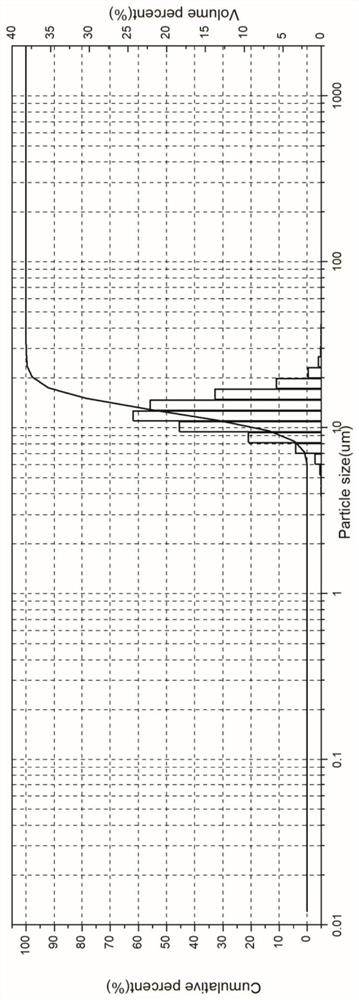

[0048] This embodiment provides a method for preparing phase-change microcapsules using a light-cured film dispersion device. Dissolve 5.0g of n-tetradecyl alcohol, 0.3g of modified epoxy acrylate, 0.15g of tripropylene glycol diacrylate, and 0.05g of α-hydroxyalkyl aryl ketone in the dark and heat up to 50°C to form a transparent solution as the dispersed phase; the dispersed phase is added For the dispersed phase storage tank 14, the temperature of the dispersed phase in the storage tank is controlled to be 40°C by a temperature sensor or thermometer 18 and a heating plate 19. Configure sodium dodecylbenzenesulfonate ion water with a mass ratio of 1 / 2000 as the continuous phase, and inject it into the continuous phase pipeline through the continuous phase feed / discharge valve 8. By controlling the continuous phase delivery pump 10, the flow rate of the continuous phase is 800 ml / min through the valve 9 and the flow meter 11, and the heat exchanger 7 is regulated to stabilize...

Embodiment 2

[0050] This embodiment provides a method for preparing epoxy resin microcapsules using a light-cured film dispersion device. Dissolve 1g of bisphenol A epoxy resin E51, 0.3g of modified epoxy acrylate, 0.1g of pentaerythritol triacrylate, 0.15g of tripropylene glycol diacrylate, and 0.05g of benzoin dimethyl ether in 10ml of acetone as a dispersed phase; The dispersed phase is added to the dispersed phase storage tank 14. Configure sodium dodecylsulfide ion water with a mass ratio of 1 / 1000 as the continuous phase, and inject it into the continuous phase pipeline through the continuous phase feed / discharge valve 8. By controlling the continuous phase delivery pump 10, the flow rate of the continuous phase is 500 ml / min through the valve 9 and the flow meter 11. Select a stainless steel metal membrane with a thickness of 2 mm and an aperture of 50 μm, open the ultrasonic part of the membrane module 3 and the LED ultraviolet light source arranged in an array in the light curing...

Embodiment 3

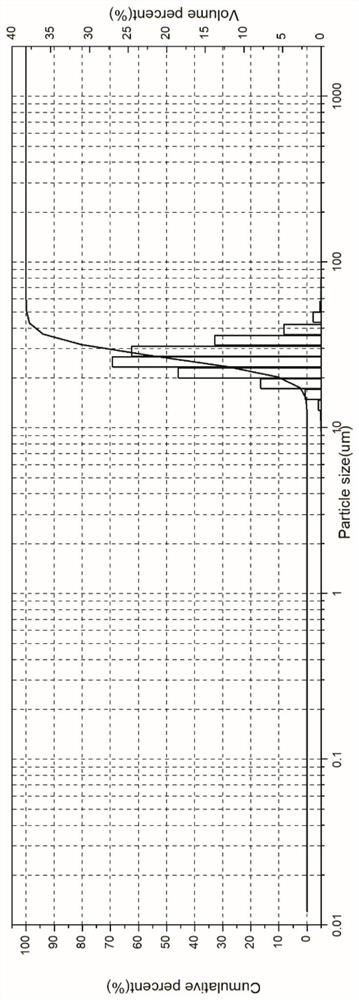

[0052] This example provides a method for preparing disperse dye microcapsules using a light-cured film dispersing device. Dissolve 5.0g Cuilan HBF, 2.0g methyl methacrylate, 0.05g 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone photoinitiator in 40mL of N,N' - in dimethylformamide as the dispersed phase. Configure a mass ratio of 1 / 1000 carboxymethylcellulose aqueous solution as the continuous phase, and the flow rate of the continuous phase is controlled to be 1000ml / min. A glass microporous membrane with a thickness of 1 mm and a pore size of 100 μm is selected, and the cycle curing time is 60 minutes. The specific process of preparing disperse dye microcapsules is as in Example 3. The laser particle size detection results of microcapsules are as follows: Figure 4 As shown, the average particle size is 32.17μm (d 50 ). The embedding rate was determined to be 48.1% by the solvent extraction method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com