Solar cell boron diffusion method capable of improving efficiency and reducing cost

A solar cell and diffusion method technology, applied in the field of solar cell boron diffusion for efficiency improvement and cost reduction, can solve problems affecting efficiency performance, high cost, and high temperature of boron diffusion process, so as to reduce recombination, reduce operating costs, and improve boron diffusion quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

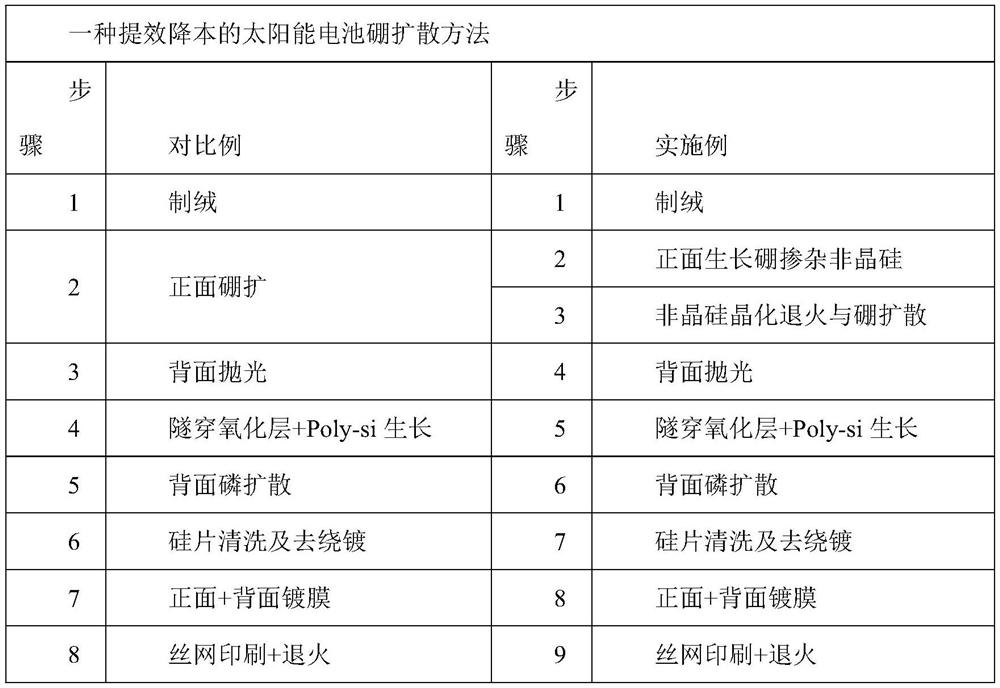

[0022] A solar cell boron diffusion method for improving efficiency and reducing cost, comprising the following steps:

[0023] 1) Use the PECVD plasma-enhanced chemical vapor deposition method on the textured sheet, keep the temperature at 450°C, and pass SiH under the tube pressure of 1800mTor 4 And BH3 deposits amorphous silicon, by adjusting the ratio of silane / borane, the doping concentration is close to 2E20cm -3 , obtain a doped amorphous silicon layer with a thickness of about 120nm;

[0024] 2) Put the silicon wafer after process 1) into a high-temperature annealing furnace;

[0025] 3) Heating: continuous feeding of 3000 sccm of N 2 Lower the temperature to 650°C and keep it for 10 minutes;

[0026] 4) Heating: continuous feeding of 3000 sccm of N 2 Lower the temperature to 950°C;

[0027] 5) Annealing: continuous feeding of 3000 sccm of N 2 , constant temperature at 950°C for 50 minutes, impurity diffusion during crystallization of doped amorphous silicon;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com