Method for preparing organic fertilizer from biogas residues

A technology of organic fertilizer and biogas residue, which is applied in the preparation of organic fertilizer, organic fertilizer, organic fertilizer equipment, etc., can solve the problems of long drying time, high energy consumption and high dehydration cost of high-voltage pulse electrolytic dehydration process, and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

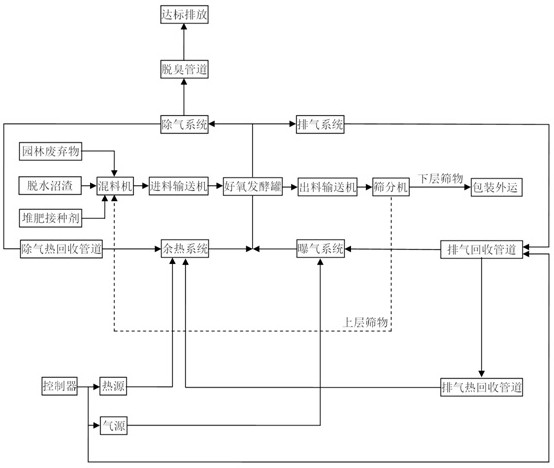

[0029] like figure 1 Shown is the first embodiment provided by the present invention, and its specific scheme is:

[0030] A method for preparing organic fertilizer from biogas residue is characterized in that: comprising the following steps:

[0031] 1) the biogas residue after the synergistic anaerobic digestion is washed with a solvent and then dried and dehydrated; as preferably, the solvent used in this step can be selected from any one or a mixture of organic solvents such as ether and chloroform, so that by The pretreatment of biogas residue removes the impurities attached to the biogas residue and added during the co-processing of sludge;

[0032] 2) Collect garden waste, sieve, clean and pulverize it; remove hard or large particles of impurities such as fruit shells and stones through sieving; dry properly after cleaning to facilitate subsequent pulverization , in this embodiment, the garden waste can be selected from branches, fallen leaves, grass and flowers, etc....

Embodiment 2

[0039]One of the differences between this example and Example 1 is that the degassing system at the top of the aerobic fermenter conducts corresponding treatment on the collected gas through the degassing heat recovery pipeline and the deodorization pipeline, and then discharges the collected gas up to the standard. The waste heat system is connected; on the one hand, the high temperature gas is introduced into the waste heat system to heat up the gas newly added to the aerobic fermentation tube, and at the same time, a large amount of gas can be prevented from being blocked in the deodorization pipeline.

[0040] Another difference between this embodiment and Embodiment 1 is that the exhaust system on the other side of the aerobic fermentation tank performs corresponding recovery treatment on the collected gas through the exhaust heat recovery pipeline and the exhaust gas recovery pipeline, and the exhaust heat is recovered. The pipeline is connected with the waste heat system...

Embodiment 3

[0043] One of the differences between this embodiment and the above-mentioned embodiment is that it further includes a controller, which provides intake air to the aeration system through an air source, the air source is connected to the controller, and the controller is based on the real-time flow rate of the exhaust gas recovery pipeline. The outlet flow rate of the gas source is adjusted in real time accordingly, so as to save the amount of gas introduced, it can also ensure the continuous and stable aerobic environment in the aerobic fermentation tube with a constant intake amount.

[0044] Another difference between this embodiment and the above-mentioned embodiment is that the temperature is raised to the waste heat system through a heat source, and the heat source is connected to the controller, and the controller adjusts the temperature of the degassing heat recovery pipe and the exhaust heat recovery pipe according to the real-time temperature of the degassing heat reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com