Preparation method of coal-based graphite/carbon composite negative electrode material for power type lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in the preparation/purification of carbon, battery electrodes, negative electrodes, etc., can solve the problems of difficulty in controlling the expansion degree of layer expansion, and achieve easy process control, easy process control, and accelerated diffusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

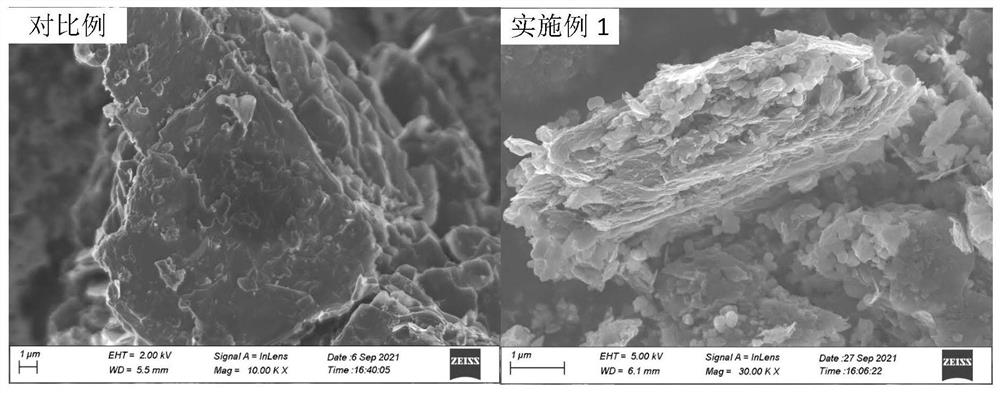

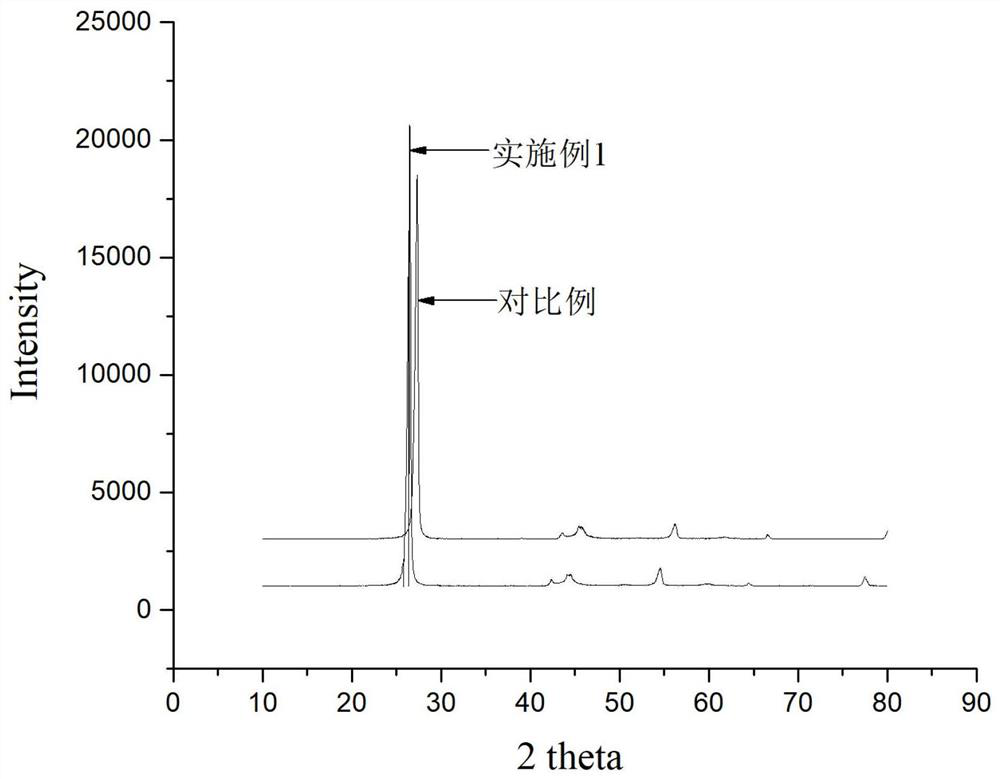

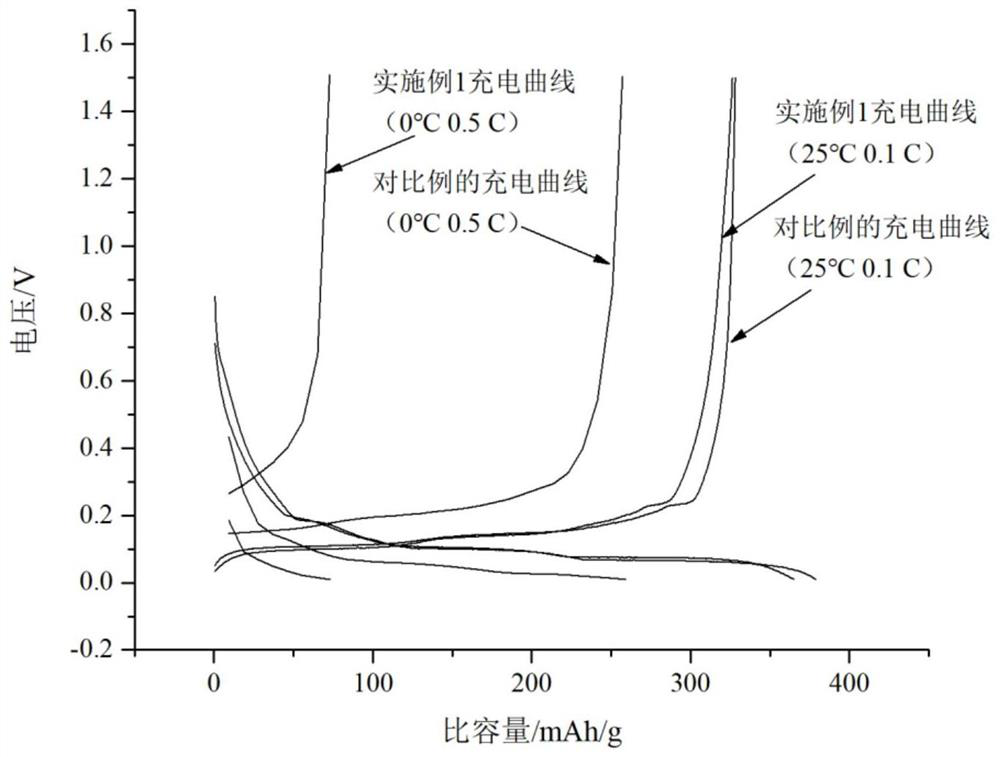

Embodiment 1

[0037] The preparation method of the coal-based graphite / carbon composite negative electrode material for the power type lithium ion battery of the present embodiment comprises the following steps:

[0038] (1) 9% deionized water and 1% surfactant stearic acid are fully and uniformly mixed with a ZSJ-8 blending machine for 2 hours at a speed of 500 rpm to obtain a graphitized anthracite with a particle size D50 of 8.0 μm and a mass percentage of 9% to obtain Moisten the mixture.

[0039] (2) Put the wet mixture obtained in the above steps into a 2.5kg popcorn machine, seal the cover, heat up to 280°C at a speed of 10°C / min by gas heating, and then keep warm at this temperature until the pressure is 0.5 MPa, maintain for 5min.

[0040] (3) The above-mentioned thermal insulation and pressure keeping popcorn machine is released to the normal pressure within 10s to complete the pressure relief process, and the precursor of the micro-expanded graphitized anthracite is obtained.

...

Embodiment 2

[0045] The preparation method of the coal-based graphite / carbon composite negative electrode material for the power type lithium ion battery of the present embodiment comprises the following steps:

[0046] (1) be that the graphitized anthracite of particle size D50 is 4.0 μm and mass percent be 20% deionized water and 2% surfactant sodium dodecylbenzene sulfonate fully and evenly mix 0.5 with VC mixer with 150rpm rotating speed hours, a wet mixture was obtained.

[0047] (2) Put the wetted mixture obtained in the above steps into a Supor SY-30FC8058Q pressure cooker, cover it well, raise the temperature to 130°C at a speed of 20°C / min by means of electric heating, and then keep it warm at this temperature until the pressure is 0.15 MPa, maintain for 10min.

[0048] (3) Release the above-mentioned heat-preserving and pressure-holding pressure cooker to normal pressure within 30s to complete the pressure relief process, and prepare the precursor of micro-expanded graphitized a...

Embodiment 3

[0053] The preparation method of the coal-based graphite / carbon composite negative electrode material for the power type lithium ion battery of the present embodiment comprises the following steps:

[0054] (1) The graphitized anthracite with a particle size D50 of 18.0 μm, 1.0% deionized water and 0.05% surfactant ethanol were fully and uniformly mixed with a stirring mixer at a speed of 35 rpm for 3 hours to obtain a wet mixture.

[0055] (2) Put the wetting mixture prepared in the above steps into Qiuzuo Technology FCF-5 reactor, heat up to 350°C at a rate of 2°C / min by microwave heating, and then keep warm at this temperature until the pressure is 1.0 MPa, maintain for 2 minutes.

[0056] (3) Release the pressure of the heat-preserved and pressure-maintained reaction kettle to normal pressure within 3s to complete the pressure relief process, and prepare the precursor of micro-expanded graphitized anthracite.

[0057] (4) Add the micro-expanded graphitized anthracite prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com