Crosslinked nano carbon plate loaded nickel selenide/manganese selenide nano composite material, preparation method thereof and sodium ion battery negative electrode

A technology of manganese selenide nano- and nano-carbon sheets, which is applied in the direction of negative electrodes, battery electrodes, nanotechnology, etc., can solve problems affecting battery cycle and rate performance, low energy density of sodium-ion batteries, and reduced electrochemical performance of batteries. Achieve excellent cycle stability, enhance cycle stability and rate performance, and enhance reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a crosslinked nano-carbon sheet loaded nickel selenide / manganese selenide nanoparticle composite material, comprising the following steps:

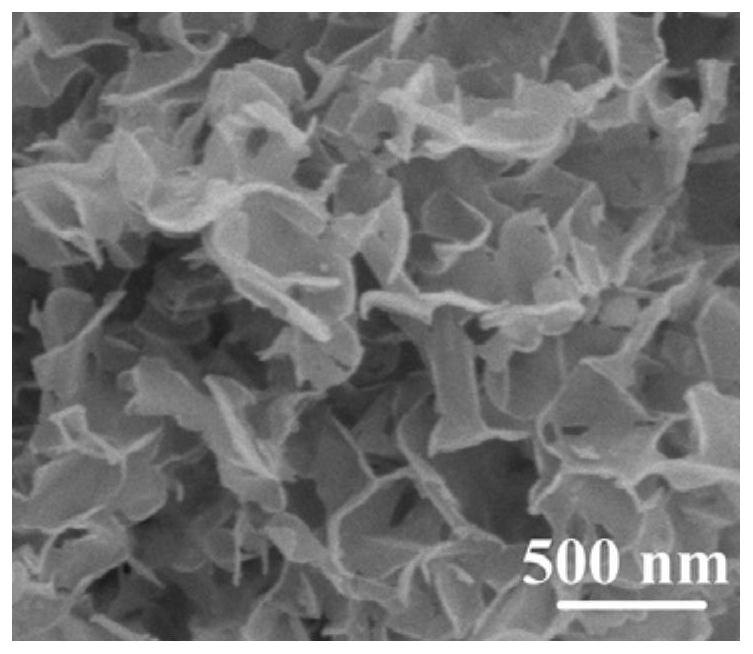

[0037] (1) Put 10g of trisodium citrate in a high-temperature tube furnace, react in a nitrogen atmosphere at 400°C for 6 hours, wash and dry the product after cooling, and obtain a cross-linked nano-carbon sheet material. The SEM image is as follows figure 1 As shown, it can be seen from the figure that its morphology is a cross-linked nanosheet;

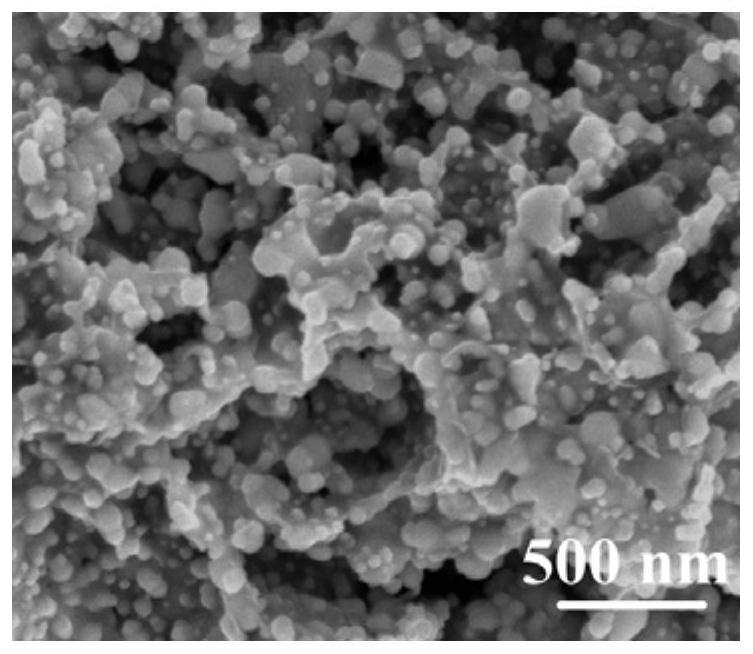

[0038] (2) Dissolve 0.172g of nickel chloride hexahydrate and 0.228g of potassium permanganate in 5mL of water, then add 0.1g of cross-linked nano-carbon sheet material to disperse in water, stir for 0.5h, and transfer to the reaction of polytetrafluoroethylene In the kettle, hydrothermal reaction at 100°C for 24 hours, the obtained product was washed with deionized water and dried to obtain the precursor;

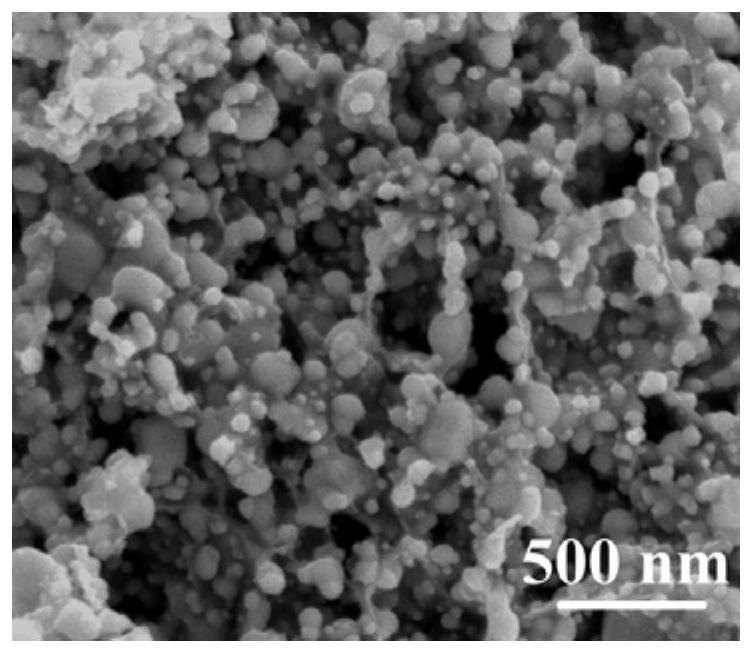

[0039] (3) Mix the precursor obtained in step (2) with ...

Embodiment 2

[0041] A method for preparing a crosslinked nano-carbon sheet loaded nickel selenide / manganese selenide nanoparticle composite material, comprising the following steps:

[0042] (1) 20 g of trisodium citrate is placed in a high-temperature tube furnace, reacted at 550° C. for 4 hours in a nitrogen atmosphere, and the product is washed and dried after cooling to obtain a cross-linked carbon nanosheet material;

[0043] (2) Dissolve 0.329g of nickel sulfate heptahydrate and 0.371g of potassium permanganate in 6mL of water, then add 0.1g of cross-linked nano-carbon sheet material to disperse in water, stir for 1h, and transfer to a polytetrafluoroethylene reaction kettle , hydrothermal reaction at 120°C for 20 hours, the obtained product was washed with deionized water and dried to obtain a precursor;

[0044] (3) Mix the precursor obtained in step (2) with 0.408g of selenium powder, place the sample in a porcelain boat, and in a tube furnace, in a mixed gas of hydrogen and argon...

Embodiment 3

[0046] A method for preparing a crosslinked nano-carbon sheet loaded nickel selenide / manganese selenide nanoparticle composite material, comprising the following steps:

[0047] (1) 40 g of trisodium citrate is placed in a high-temperature tube furnace, reacted at 700° C. for 3 hours in a nitrogen atmosphere, and the product is washed and dried after cooling to obtain a cross-linked carbon nanosheet material;

[0048] (2) Dissolve 0.479g of nickel nitrate hexahydrate and 0.521g of potassium permanganate in 8mL of water, then add 0.1g of cross-linked nano-carbon sheet material to disperse in water, stir for 2h, and transfer to a polytetrafluoroethylene reaction kettle , hydrothermal reaction at 140°C for 15 hours, the obtained product was washed with deionized water and dried to obtain a precursor;

[0049] (3) Mix the precursor obtained in step (2) with 0.573g of selenium powder, place the sample in a porcelain boat, and in a tube furnace, in a mixed gas of hydrogen and argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com