Sitagliptin phosphate tablet and preparation method thereof

A technology of sitagliptin phosphate and tablet core, which is applied in the field of sitagliptin phosphate tablet and its preparation, can solve the problems of complex preparation process, reduce the content of active components, increase the amount of excipients, etc., and avoid agglomeration of particles , improve stability, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

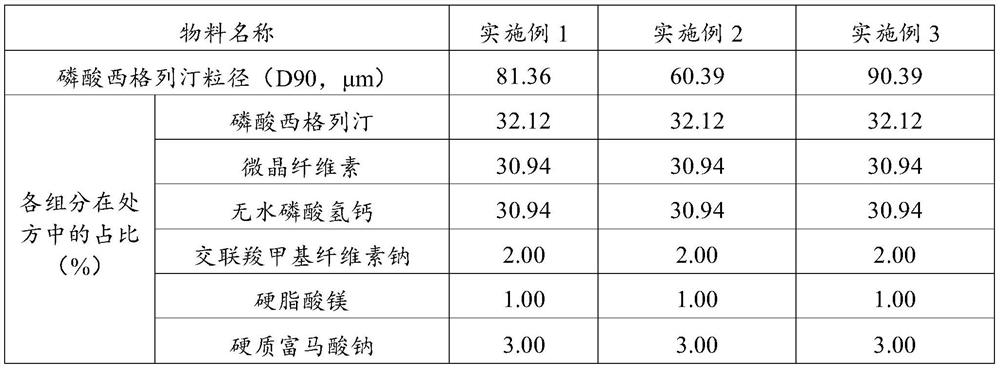

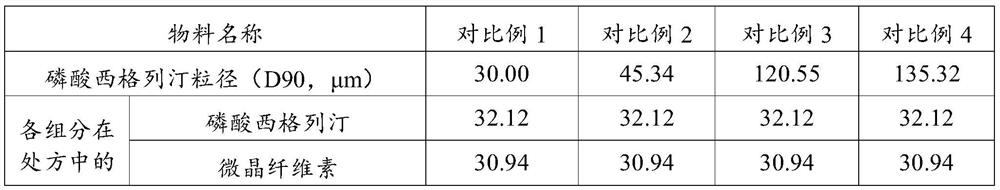

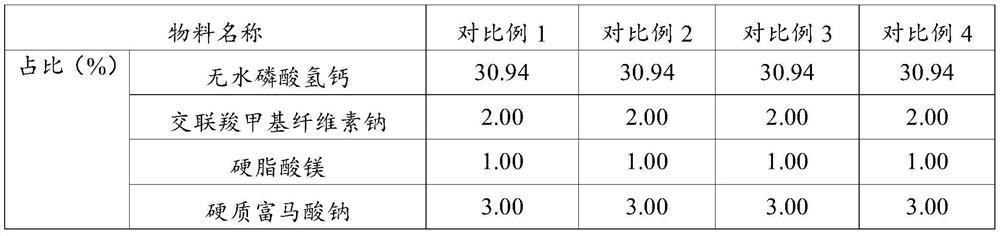

[0042] The formula of each sitagliptin phosphate tablet in embodiment 1~3 is as shown in table 1 below:

[0043] Table 1 embodiment 1~3 formula of sitagliptin phosphate tablet (in every 20000 tablets)

[0044]

[0045] The above-mentioned examples 1-3 are prepared by the following preparation process, and the specific operation is as follows:

[0046] (1) Sitagliptin phosphate monohydrate, microcrystalline cellulose, anhydrous calcium hydrogen phosphate and cross-linked carmellose sodium get prescription quantity in the wet granulator, in the stirring paddle rotating speed is 150rpm, cut Knife speed is 500rpm, mixing and stirring for 5min to obtain premix 1;

[0047] (2) Transfer the above-mentioned premix 1 to the mixing tank, and stir for 10 minutes to obtain the premix 2;

[0048] (3) Add sodium stearyl fumarate in the above mixing tank, add magnesium stearate after stirring for 5 minutes, continue stirring for 5 minutes, and obtain the total blend;

[0049] (4) compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com