Preparation method and application of nitrogen-doped porous carbon coated cobalt diselenide composite material

A technology of nitrogen-doped porous carbon and cobalt diselenide is applied in the preparation/purification of carbon, binary selenium/tellurium compounds, metal selenide/tellurium compounds, etc. Insufficient volume expansion limit and other problems, to achieve the effect of reducing interface resistance, improving cycle stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

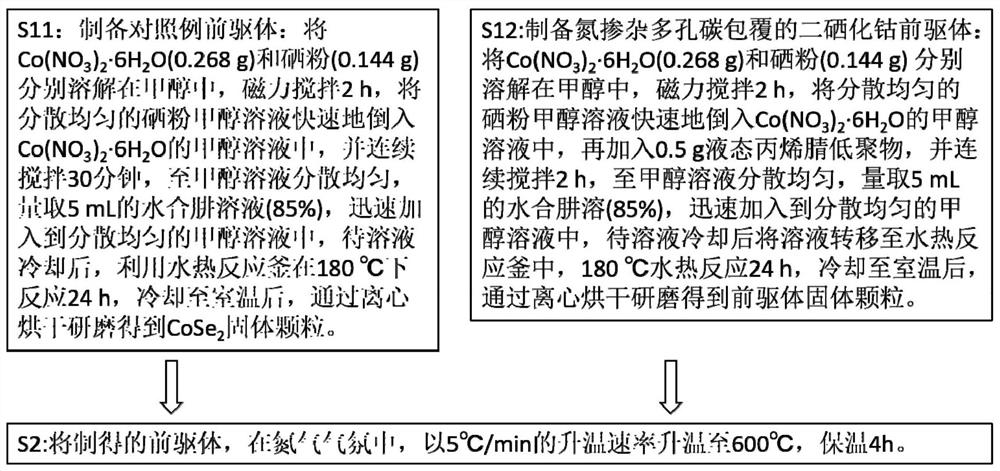

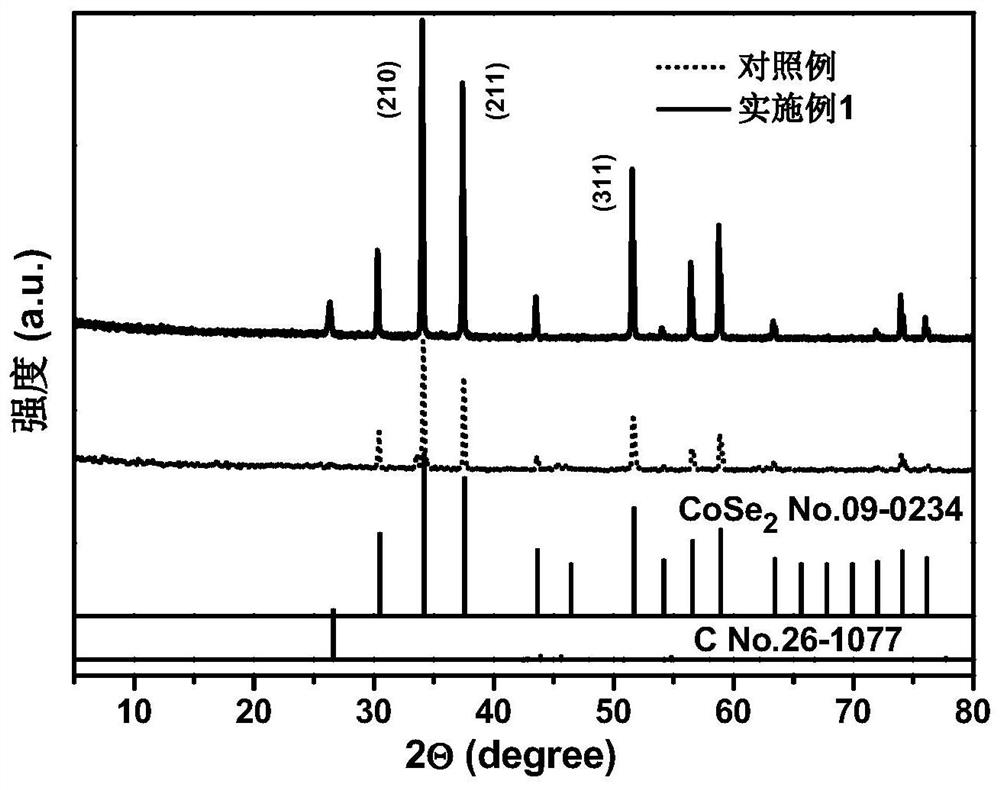

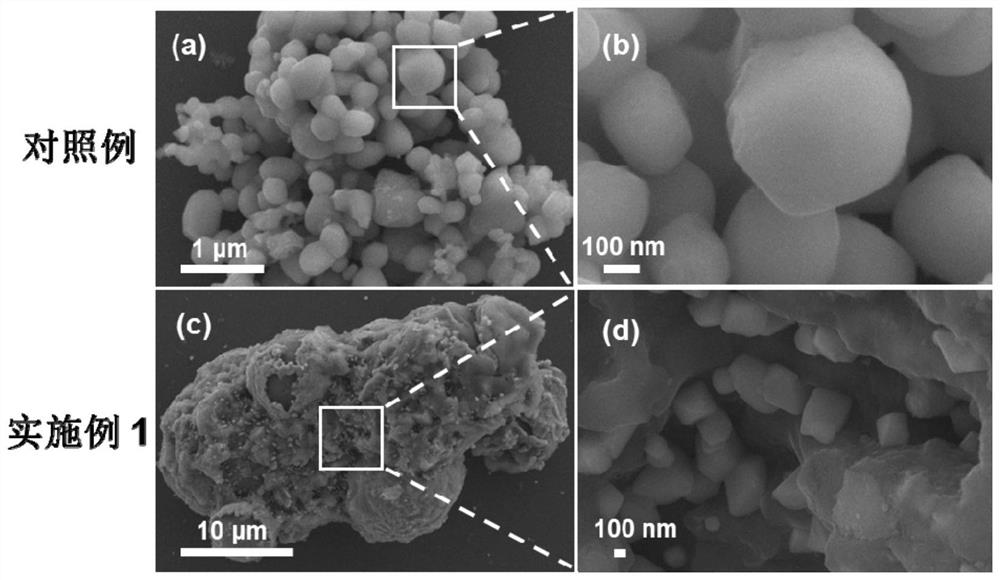

[0043] A method for preparing a nitrogen-doped porous carbon-coated cobalt diselenide negative electrode material and its application, comprising the following steps:

[0044] Will Co(NO 3 ) 2 ·6H 2 O (0.291g) and selenium powder (0.157g) were dissolved in methanol respectively, and magnetically stirred for 2h, and the evenly dispersed methanol solution of selenium powder was quickly poured into Co(NO 3 ) 2 ·6H 2 O methanol solution, then add 0.5g liquid acrylonitrile oligomer, and continue to stir for 2h, until the methanol solution is uniformly dispersed, measure 5mL of hydrazine hydrate solution (mass fraction is 85%), and quickly add to the uniformly dispersed methanol solution In the process, after the solution is cooled, transfer the solution to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 24 hours. After cooling to room temperature, collect the precipitate by centrifugation, dry it at a heating rate of 5°C / min to 600°C, and keep it ...

Embodiment 2

[0046] Will Co(NO 3 ) 2 ·6H 2 O (0.268g) and selenium powder (0.144g) were dissolved in methanol respectively, and magnetically stirred for 1h, and the evenly dispersed methanol solution of selenium powder was quickly poured into Co(NO 3 ) 2 ·6H 2 O methanol solution, then add 1g of liquid acrylonitrile oligomer, and continue to stir for 1h, until the methanol solution is evenly dispersed, measure 5mL of hydrazine hydrate solution (mass fraction is 85%), and quickly add it to the uniformly dispersed methanol solution , after the solution is cooled, transfer the solution to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 160°C for 30 hours, and after cooling to room temperature, collect the precipitate by centrifugation, dry it at a heating rate of 8°C / min to 800°C, and keep it for 4 hours. Used to remove residual selenium powder. After cooling, grind and sieve to prepare nitrogen-doped carbon-coated cobalt diselenide composite material.

Embodiment 3

[0048] Will Co(NO 3 ) 2 ·6H 2 O (0.268g) and selenium powder (0.144g) were dissolved in methanol respectively, and magnetically stirred for 3h, and the evenly dispersed methanol solution of selenium powder was quickly poured into Co(NO 3 ) 2 ·6H 2 O methanol solution, then add 0.8g liquid acrylonitrile oligomer, and continue to stir for 3h, until the methanol solution is uniformly dispersed, measure 8mL of hydrazine hydrate solution (mass fraction is 85%), and quickly add to the uniformly dispersed methanol solution After the solution is cooled, transfer the solution to a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 170°C for 26 hours. After cooling to room temperature, collect the precipitate by centrifugation, dry it at a rate of 5°C / min to 700°C, and keep it for 5 hours. , used to remove residual selenium powder. After cooling, grind and sieve to prepare nitrogen-doped carbon-coated cobalt diselenide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com