Preparation method of hydroxylated magnetic graphene oxide adsorbent

An oxide stone and hydroxylation technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of difficult separation and recovery, limitation of large-scale application, and cost increase, etc. To achieve the effect of excellent adsorption capacity, low cost of raw materials, rapid separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

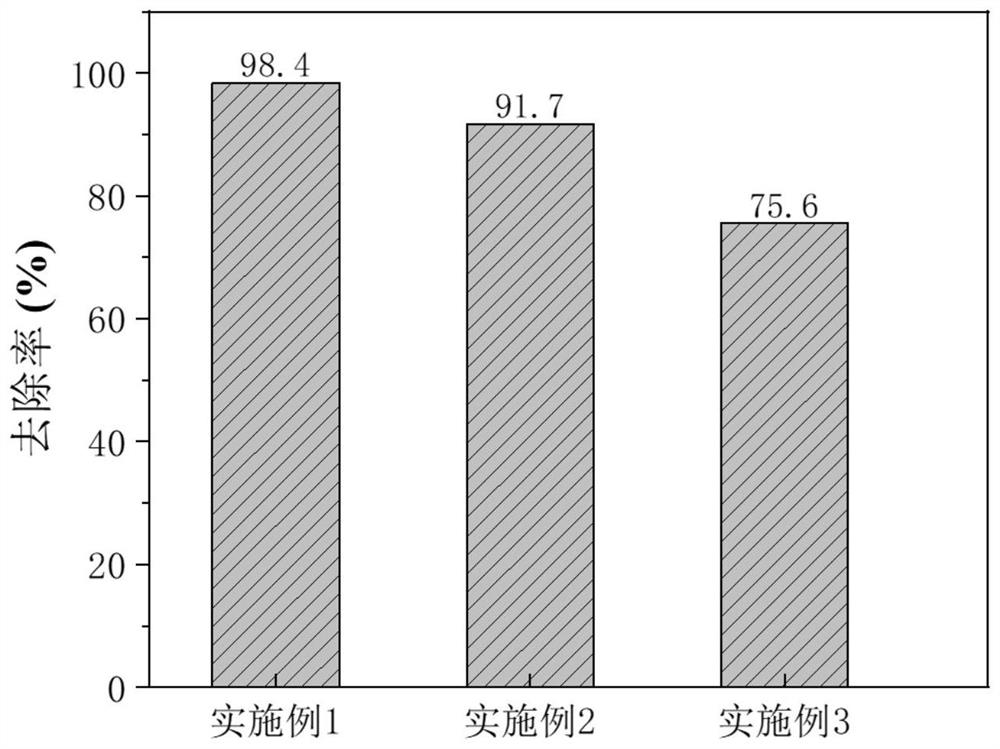

Embodiment 1

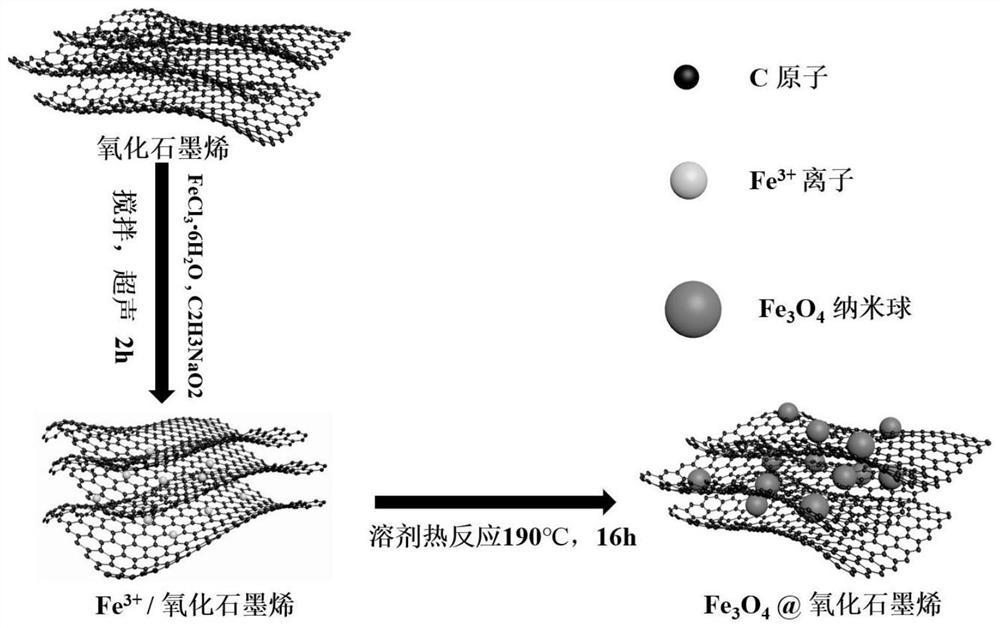

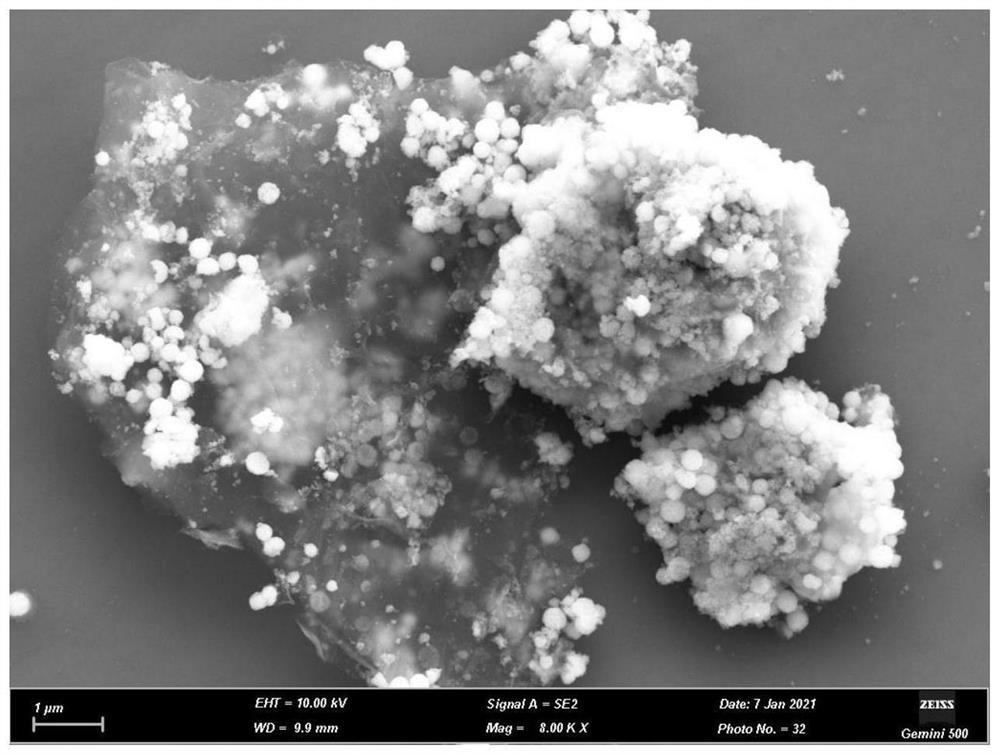

[0024] (1) Weigh 1.0 g of graphene oxide, stir it magnetically for 30 minutes, then use a cell pulverizer to ultrasonically disperse it for 30 minutes, and disperse it in an ethylene glycol solvent. Weigh 2 g of sodium dodecylbenzene sulfonate as a surfactant, and stir for 30 min until it is completely dissolved. Subsequently, 1.5 g of ferric chloride pentahydrate was added, and stirred for 2 h to ensure that the iron ions were fully combined with the graphene oxide sheets. Finally, 10.8 g of sodium oxalate was added and stirred for 30 min until a uniform suspension was formed.

[0025] (2) Transfer the suspension prepared in (1) to a hydrothermal reaction kettle, then put the reaction kettle into an oven, set the reaction temperature to 190° C., and the reaction time to 16 hours. After the reaction is over, take it out after cooling to room temperature, use a strong magnet to separate, use deionized water and absolute ethanol as cleaning agents, wash each for 3 times, put it...

Embodiment 2

[0028] (1) Weigh 1.0 g of graphene oxide, stir it magnetically for 30 minutes, then use a cell pulverizer to ultrasonically disperse it for 30 minutes, and disperse it in an ethylene glycol solvent. Weigh 2 g of sodium dodecylbenzene sulfonate as a surfactant, and stir for 30 min until it is completely dissolved. Subsequently, 1.5 g of ferric chloride pentahydrate was added, and stirred for 2 h to ensure that the iron ions were fully combined with the graphene oxide sheets. Finally, 10.8 g of sodium oxalate was added and stirred for 30 min until a uniform suspension was formed.

[0029] (2) Transfer the suspension prepared in (1) to a hydrothermal reaction kettle, then put the reaction kettle into an oven, set the reaction temperature to 190° C., and the reaction time to 16 hours. After the reaction is over, take it out after cooling to room temperature, use a strong magnet to separate, use deionized water and absolute ethanol as cleaning agents, wash each for 3 times, put it...

Embodiment 3

[0032] (1) Weigh 0.5 g of graphene oxide, stir it magnetically for 30 min, and then disperse it in an ethylene glycol solvent using an ultrasonic cell pulverizer for 30 min. Weigh 2 g of sodium dodecylbenzene sulfonate as a surfactant, and stir for 30 min until it is completely dissolved in the dispersion. Subsequently, 1.5 g of ferric chloride pentahydrate was added, and stirred for 2 h to ensure that the iron ions were fully combined with the graphene oxide sheets. Finally, 10.8 g of sodium oxalate was added and stirred for 30 min until a uniform suspension was formed.

[0033] (2) Transfer the suspension prepared in (1) to a hydrothermal reaction kettle, then put the reaction kettle into an oven, set the reaction temperature to 190° C., and the reaction time to 16 hours. After the reaction is over, take it out after cooling to room temperature, use a strong magnet to separate, use deionized water and absolute ethanol as cleaning agents, wash each for 3 times, put it in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com