Method for treating livestock farm wastewater through biological flocculation-electrodialysis and application of method

A technology of biological flocculation and electrodialysis, applied in biological water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve problems such as secondary pollution of the atmospheric environment, achieve good flocculation effect, and promote solidification The effect of liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides an application of a bioflocculation-electrodialysis method for treating farm wastewater in the treatment of thick slurry wastewater from pig farms.

[0068] The concentration of each pollutant in the concentrated slurry wastewater produced by primary solid-liquid separation after the collection of pig farm manure is as follows: COD5756mg / L, SS 6623mg / L, total nitrogen 551mg / L, ammonia nitrogen 477mg / L, TP 236mg / L, K+ 308 mg / L, pH 8.21.

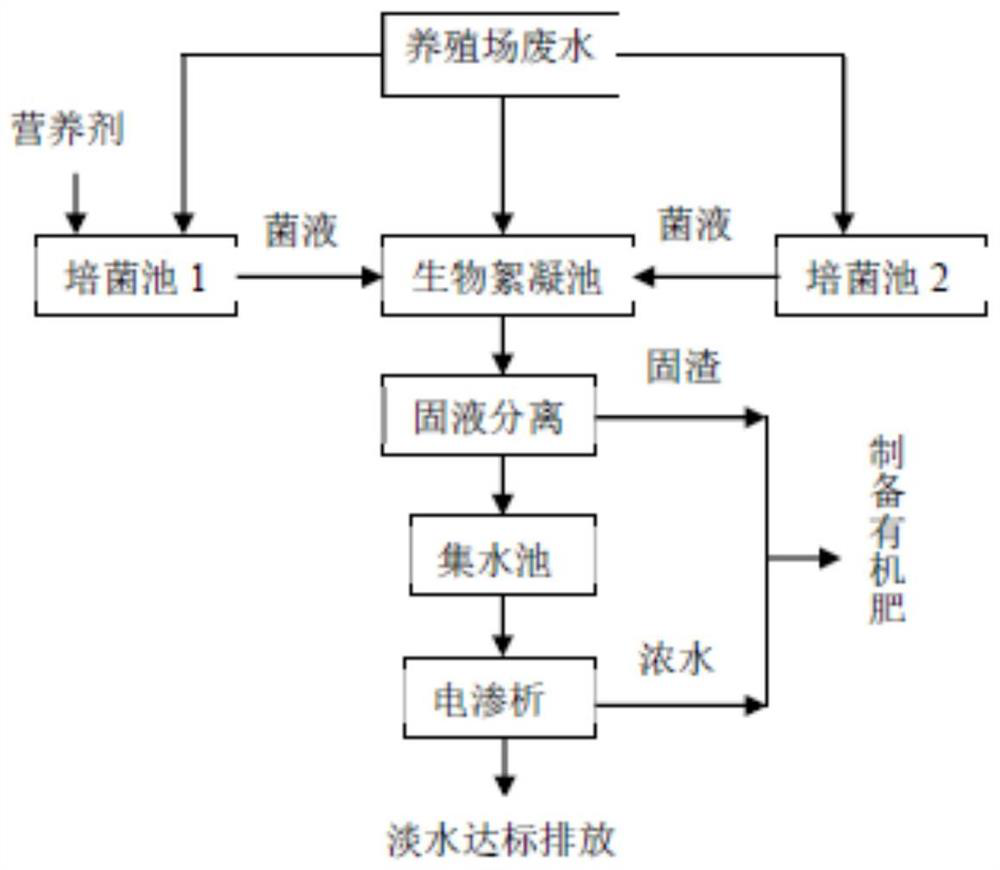

[0069] The application process flow chart is as follows figure 1 As shown, the infrastructure includes a bioflocculation system and an electrodialysis system. The bioflocculation system includes a microbial culture tank, a flocculation tank, a plate and frame filter press and a water collection tank; the electrodialysis system includes a complete set of electrodialysis equipment, as follows:

[0070] Preparation of microbial bacterial liquid:

[0071] In 2 8m each with adjustable speed mixer and aeration and o...

Embodiment 2

[0083] This embodiment provides an application of a bioflocculation-electrodialysis method for treating farm wastewater in the treatment of thick slurry wastewater from dairy farms.

[0084] The concentrations of pollutants in the concentrated slurry wastewater produced by primary solid-liquid separation after the collection of dairy farm manure are as follows: COD21252mg / L, SS 10347mg / L, total nitrogen 2298mg / L, ammonia nitrogen 1699mg / L, TP 322mg / L, K + 401mg / L, pH8.25. The application process flow chart is as follows figure 1 As shown, the infrastructure includes a bioflocculation system and an electrodialysis system. The bioflocculation system includes a microbial culture tank, a flocculation tank, a plate and frame filter press and a water collection tank; the electrodialysis system includes a complete set of electrodialysis equipment, as follows:

[0085] Preparation of microbial bacterial liquid:

[0086] In 2 10m each with adjustable speed mixer and aeration and oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com