System and method for recycling carbon, nitrogen and phosphorus resources by cracking excess sludge through microwave assisted by wave absorber

A technology for recovering excess sludge and carbon, which is applied in the direction of biological sludge treatment, pyrolysis sludge, sludge treatment, etc., can solve the problems of uneven metabolic rate, unfavorable treatment and disposal, and reduced gas production rate, etc., to achieve increased Effects of methane production, reduction of irradiation, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

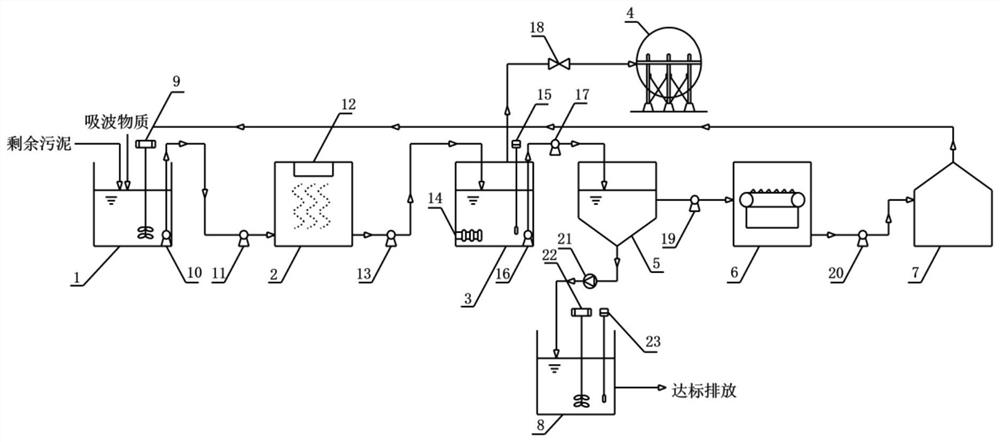

[0053] A method for recovering carbon, nitrogen and phosphorus resources from excess sludge assisted by microwave absorbers, comprising the following steps:

[0054] Step S1: Take the remaining sludge from the secondary settling tank of an urban sewage treatment plant and place it in the mixing tank 1, and concentrate it by gravity for 24 hours. The TS content of the original sludge is 20,000 mg / L, the VS content is 6,000 mg / L, and the TCOD content is 16,300 mg / L. L, the content of SCOD is 730mg / L, the content of TN is 670mg / L, the content of TP is 267mg / L, the content of ammonia nitrogen in the supernatant is 35mg / L, and the content of phosphate is 16mg / L. Add 0.35g / gVS activated carbon to the mixing tank 1, and mix evenly through the stirring device.

[0055] Step S2: Lift the sludge mixture to the pipeline through the first submersible sewage pump 10, enter the microwave cracking chamber 2 through the first delivery pump 11, start the microwave generator 12 to crack the slu...

Embodiment 2

[0061] A method for recovering carbon, nitrogen and phosphorus resources from excess sludge assisted by microwave absorbers, comprising the following steps:

[0062] Step S1: Take the remaining sludge from the secondary settling tank of an urban sewage treatment plant and place it in the mixing tank 1, and concentrate it by gravity for 24 hours. The TS content of the original sludge is 30000 mg / L, the VS content is 8000 mg / L, and the TCOD content is 18800 mg / L. L, the content of SCOD is 940mg / L, the content of TN is 810mg / L, the content of TP is 293mg / L, the content of ammonia nitrogen in the supernatant is 42mg / L, and the content of phosphate is 21mg / L. Add 0.25g / gVS carbonized sludge to the mixing tank 1, and mix evenly through the stirring device.

[0063] Step S2: Lift the sludge mixture to the pipeline through the first submersible sewage pump 10, enter the microwave cracking chamber 2 through the first delivery pump 11, start the microwave generator 12 to crack the sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com