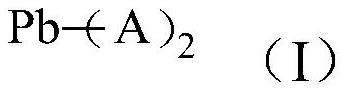

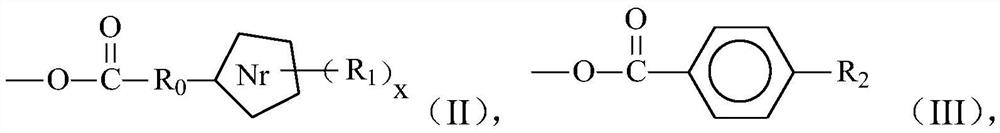

Lead compound, preparation method and application thereof and lubricating oil composition

A lead compound and compound technology, applied in lubricating compositions, carboxylate preparation, organic chemistry, etc., can solve the problems of poor oil solubility, affecting extreme pressure and anti-wear effects, etc., to ensure normal work, good solubility, The effect of good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] 1) preparation of tetradecylacetophenone

[0084] In a 1000 ml three-necked flask with temperature-controlled stirring, add 350 ml of CCl 4 , 50 grams of anhydrous AlCl 3 and 50 grams of acetyl chloride (0.637mol), add 174 grams of tetradecylbenzene (0.634mol) dropwise, control the rate of addition so that the temperature of the material is between 0 and 5°C, and react at 20 to 25°C after the addition is complete 1h, then the organic layer was separated from the reaction mixture, washed with acid and water until neutral, dried with anhydrous sodium sulfate, filtered, and evaporated to remove the solvent to obtain tetradecylacetophenone.

[0085] 2) Oxidation of Tetradecyl Acetophenone to Alkyl Benzoic Acid

[0086] At room temperature, 200 ml of chloroform, 120 ml of NaOCl and 20 g of NaOH were added to a 1000 ml three-necked flask. 31.65 g (0.1 mol) of p-tetradecylacetophenone was added dropwise, and after the addition was completed, the temperature was raised to re...

preparation example 1

[0101] This preparation example is used to illustrate the preparation method of the polyalkylcyclopentane used in the following examples.

[0102] Mix n-decyl alcohol, solid potassium hydroxide and dicyclopentadiene and put them into a flask equipped with a stirrer, a separatory funnel, a condenser tube, a water separator and a thermometer for heating reaction. The reaction temperature is 220-250°C, When no more water is generated in the water vessel, the reaction is stopped, and the reaction product is washed with water, dried and filtered to obtain poly-n-decylcyclopentadiene. Poly-n-decylcyclopentadiene and n-heptane are made into a solution with a dilution rate of 10%. After mixing 200g of this solution with 3.6g of amorphous nickel catalyst, put it into an autoclave, and feed hydrogen until the hydrogen pressure reaches 5MPa , heated to 155°C under stirring, reacted for 20h, filtered the reaction product after cooling, and removed the solvent to obtain poly-n-decylcyclope...

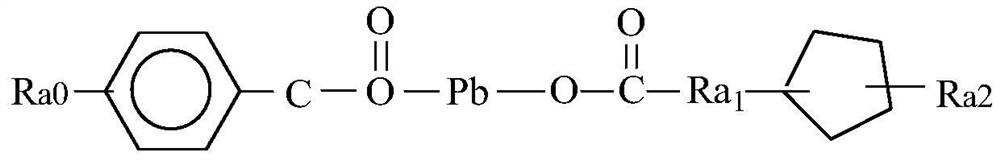

Embodiment 1

[0104] In 1000 milliliters of there-necked flasks with temperature control, water cooling, stirring, add 127.5 grams (0.27mol) of naphthenic acid A earlier, tetradecylbenzoic acid (total acid value is 167mgKOH / g, mass fraction is 95%, the average relative The molecular weight is 318) 63.6 grams (0.2mol), stir the material, when the temperature of the material rises to 115°C, slowly add 35.7 grams (0.16mol) of lead oxide and 1.7 grams of propanol within 30 minutes. After 2 hours of constant temperature reaction, then add 100 grams of naphthenic acid A (0.21mol), slowly add lead oxide 35.7 grams (0.16mol) in 30 minutes, then react for 4 hours, treat that there is no lead oxide solid particle in the material, the material Cool down when it is transparent, add 200 grams of No. 120 solvent gasoline at 60 ° C, filter after dilution, and distill the filtrate to obtain 348 grams of extreme pressure antiwear agent A (theoretical product amount is 357 grams) of viscous dark brown. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com