Device applied to separation and recovery of carbonate in salt lake water

A recovery device and technology of carbonate ions, applied in the direction of alkali metal carbonate, lithium carbonate;/acid carbonate, water pollutants, etc., can solve the problem of low recovery rate, short effective production time, and production time Long and other problems, to achieve the effect of efficient recycling, excellent lighting conditions, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

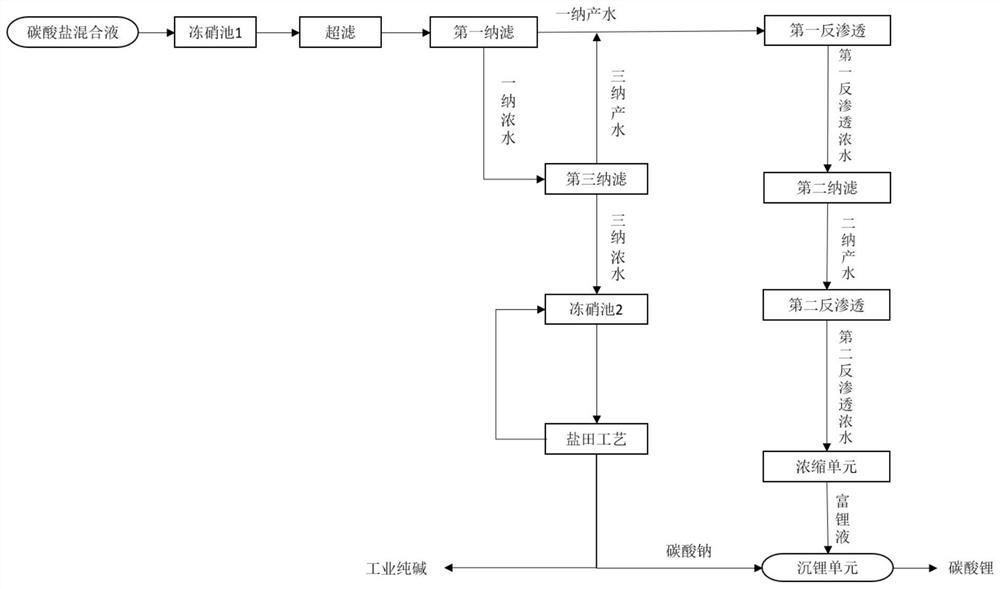

[0053] In this embodiment 1, a kind of device applicable to the separation and recovery of carbonate in salt lake water is provided, including:

[0054] An ultrafiltration unit is used to filter the solution to be treated containing carbonate ions to obtain ultrafiltration product water;

[0055] The first nanofiltration separation unit is used to separate the carbonate ion for the first time from the ultrafiltration product water to obtain a nano concentrated water and a nano product water;

[0056] The first reverse osmosis unit is used to process the first sodium product water to obtain the first reverse osmosis concentrated water and the first reverse osmosis product water;

[0057] The second nanofiltration separation unit is used to separate and purify the first reverse osmosis concentrated water to obtain dina concentrated water and dina product water, and the dina product water is a purified lithium solution, so that the dina concentrate water is obtained. The nano-co...

Embodiment 2

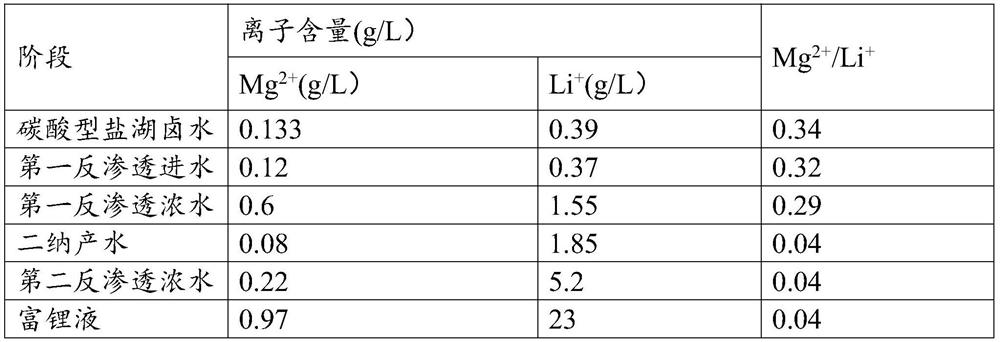

[0081] Present embodiment 2 provides the method for separating and reclaiming carbonate in a kind of carbonate type salt lake, combines figure 1 Shown is the flow process of this embodiment, the carbonated salt lake brine in embodiment 2 comes from a certain carbonated salt lake in a certain area, the chloride ion content in this carbonated salt lake brine is 62.28g / L, the carbonate content is 13.68g / L, lithium ion content of 0.39g / L, magnesium ion content of 0.133g / L, sulfate content of 5.01g / L, and sodium ion content of 47.66g / L.

[0082] The method of the present embodiment comprises the following steps:

[0083] The carbonated salt lake brine is injected into the frozen nitric acid tank 1 for freezing nitric acid. After solid-liquid separation, the upper layer liquid is taken into short-process ultrafiltration filtration to obtain ultrafiltration product water.

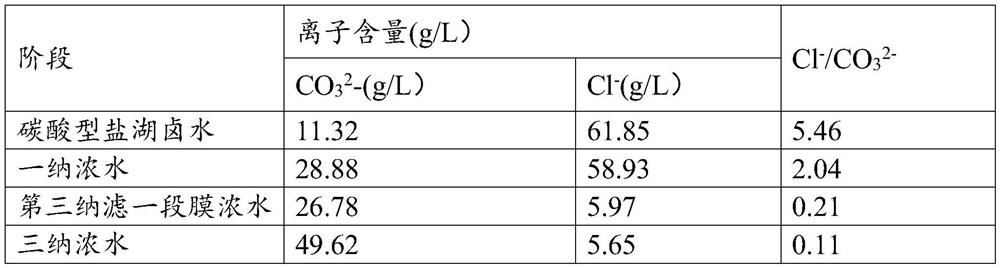

[0084] The ultrafiltration product water enters the first nanofiltration separation unit for separation to obt...

Embodiment 3

[0100] This embodiment provides a method for separating and reclaiming carbonate radicals in carbonated salt lakes, combining figure 1 Shown is the flow process of this embodiment, the method of this embodiment includes the following steps:

[0101] The carbonated salt lake brine is subjected to short-process ultrafiltration to obtain ultrafiltration product water.

[0102] The ultrafiltration product water enters the first nanofiltration separation unit for separation to obtain a nano-product water and a nano-concentrated water. Among them, the concentration of lithium ion in the one-nano concentrated water is 0.35g / L, the concentration of magnesium ion is 0.131g / L, the ratio of magnesium to lithium is 0.37, the concentration of chloride ion in the one-nano concentrated water is 55.18g / L, and the concentration of carbonate is 22.57g / L , The mass ratio of chloride ion to carbonate is 2.44.

[0103] The one-nano product water enters the first reverse osmosis unit for concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com