Oxidase whole-cell catalyst and method for preparing high-optical-purity R-type 1, 3-butanediol by using oxidase whole-cell catalyst

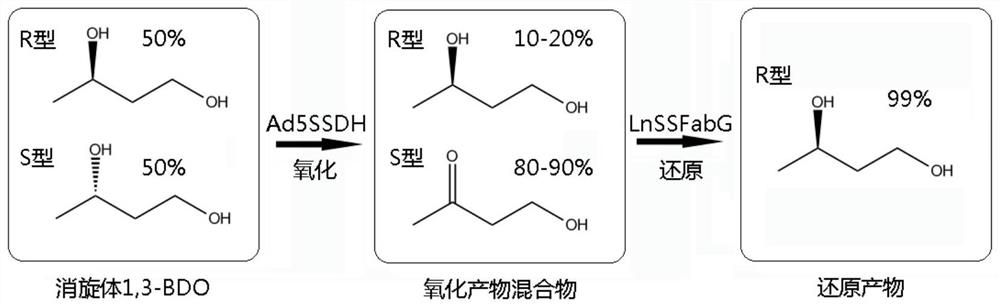

A whole-cell catalyst and oxidase technology, which is applied in the field of biocatalytic preparation of R-type 1,3-butanediol, can solve the problems of toxic excipients polluting the environment, high price of threonine, and difficult control, etc., to reduce reaction impurities, The effect of high reaction efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of genetically engineered bacteria with high production of oxidase or reductase:

[0034] Primers were designed according to the sequences of the Ad5SSDH and LnSSFabG genes of Saccharolobus solfataricus:

[0035] Ad5SSDH, its sequence is shown in the sequence table SEQ NO.1, its amplification primer:

[0036] Forward primer: CGC CATATG agagcagttagattggtagaaataggaa, the underlined sequence is the enzyme cutting site NdeI.

[0037] Reverse primer: CC GGATCC tggtattaatacttgccttcc, the underlined sequence is the HindIII restriction site. The sequence of the gene product is shown in SEQ NO.2 of the sequence table.

[0038] The two ends of the gene sequence obtained after PCR amplification have NdeI and HindIII sites, and the gene sequence obtained after PCR amplification is inserted into the pET30a vector, and the high-expression genetic engineering vector plasmid obtained is named pET30Ad5SSDH, and then The plasmid pET30Ad5SSDH was transformed into the re...

Embodiment 2

[0058] Expression and purification of oxidase Ad5SSDH or reductase LnSSFabG

[0059] (1) Activation in the seed culture medium The colonies of the high-yield oxidase genetically engineered bacteria and the high-yield reductase genetically engineered bacteria on the petri dish were respectively placed in 5mL LB (Kan100μg / mL) medium, and the seeds activated overnight at 37°C and 200rpm liquid.

[0060] (2) Fermentation culture Inoculate 10% of overnight activated seed solution into 800 mL LB fermentation medium (kan 100 g / mL) and culture at 37° C. and 200 rpm until OD600=0.6 in the mid-logarithmic phase.

[0061] (3) Induction culture Lactose was added for induction at the mid-log phase, so that the final concentration was 1 mM, and the induction culture was carried out at 25-30° C. and 180 rpm for 4-6 hours.

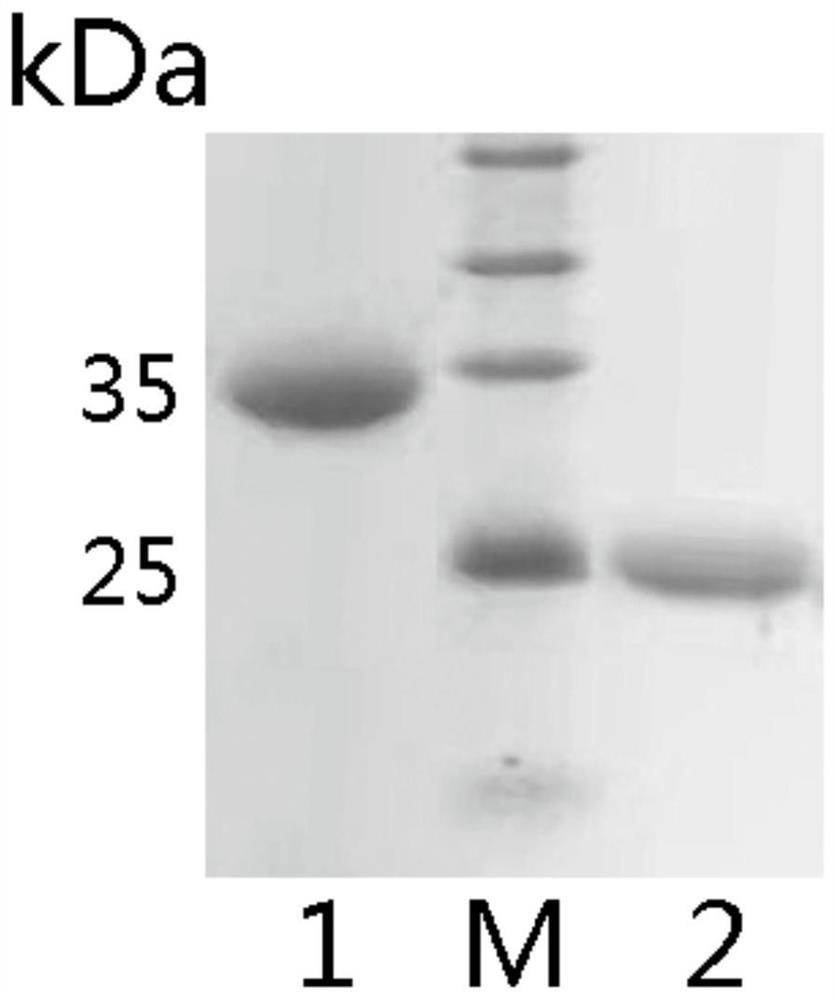

[0062] (4) SDS-PAGE Take 4 mL of the fermented broth that has been induced, centrifuge at 12,000 rpm for 90 sec, add 800 μL of deionized water, and sonicate for 5 min. ...

Embodiment 3

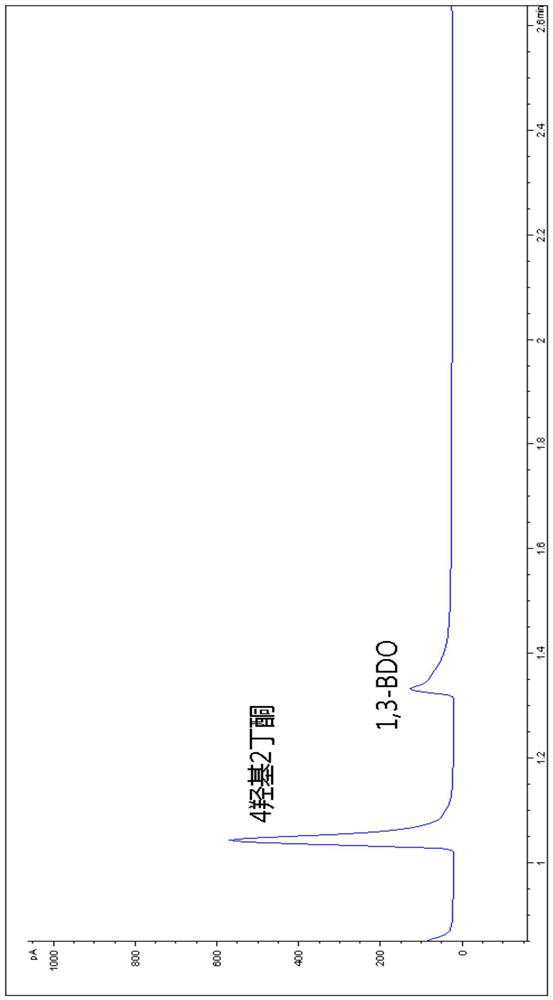

[0069] The method for preparing Ad5SSDH oxidase whole-cell catalyst and the experiment of converting racemate 1,3-BDO into R-1,3-BDO by using the whole-cell catalyst:

[0070] (1) Activation of seed medium Pick a single colony on a petri dish and place it in 5 mL of LB (Kan 100 μg / mL) medium, and activate overnight at 37° C. and 200 rpm.

[0071] The seed medium is LB medium, and the formula is as follows: peptone 10g / L, yeast extract 5g / L, NaCl 10g / L; NH3·H2O adjusted to pH 7.0, the plate medium is LB medium and 15g / L agar powder is added, Sterilize at 121°C for 20 minutes.

[0072] (2) Fermentation culture Inoculate 10% of the overnight activated seed solution into 1L TB fermentation medium (Kan 100 μg / mL) and culture at 37°C and 200 rpm until mid-log phase OD600=0.6-1.

[0073] The fermentation medium is TB medium, and the formula is as follows: peptone 12g / L, yeast extract 24g / L, glycerin 4ml / L, set the volume to 900mL, and prepare 100ml 0.17M potassium dihydrogen phospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com