Method for regulating and controlling crystal face orientation of metal material, metal material obtained through method and application of metal material

A technology of metal material and crystal plane orientation, applied in structural parts, electrolytic components, circuits, etc., can solve the problems of growth rate difference, unfavorable metal uniform deposition and peeling, etc., and achieve the effect of eliminating zinc dendrites and improving electrode activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

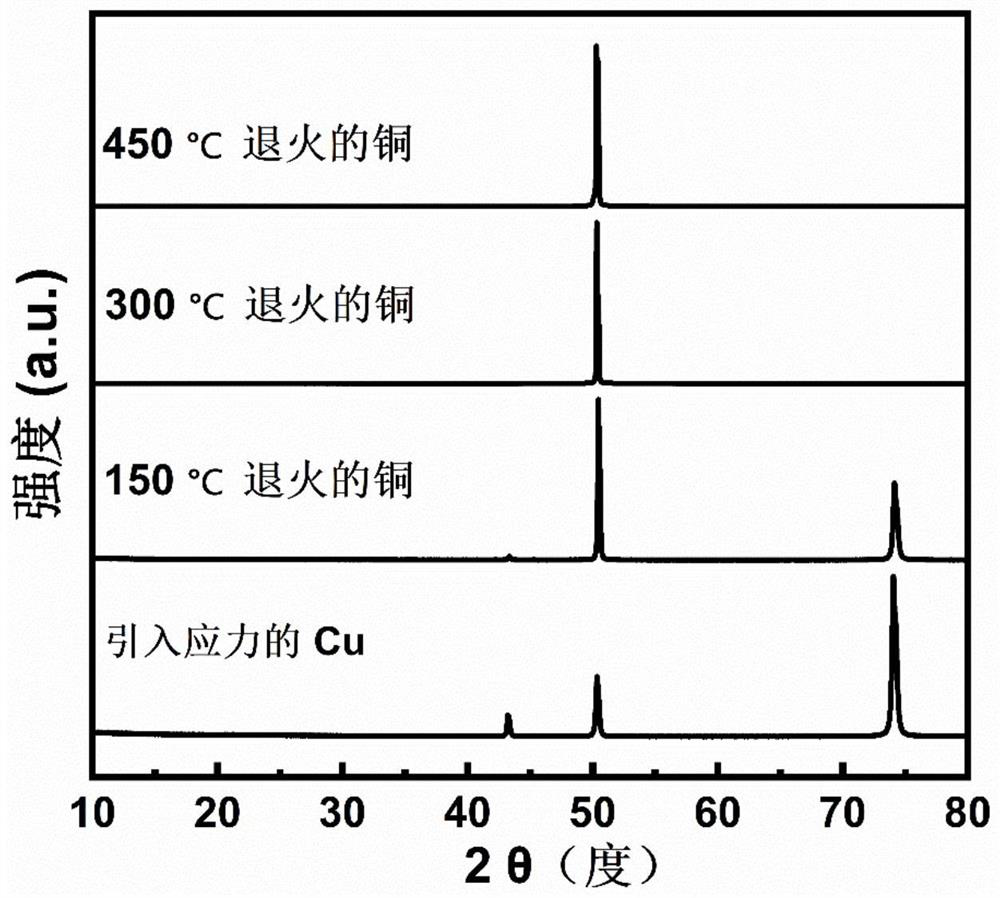

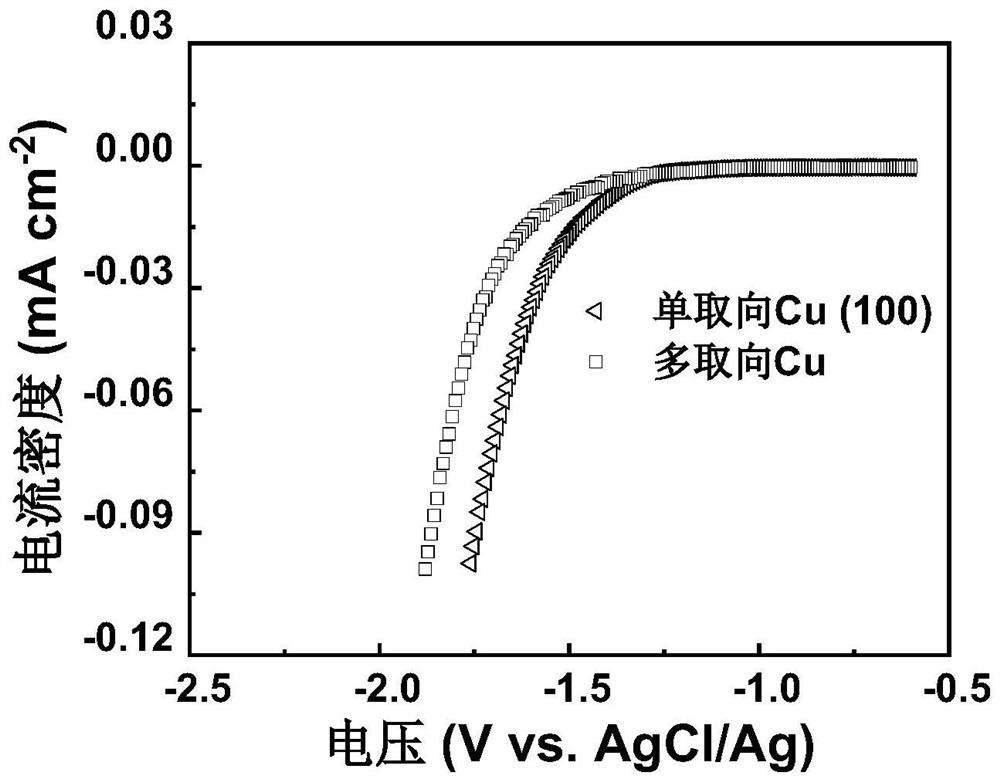

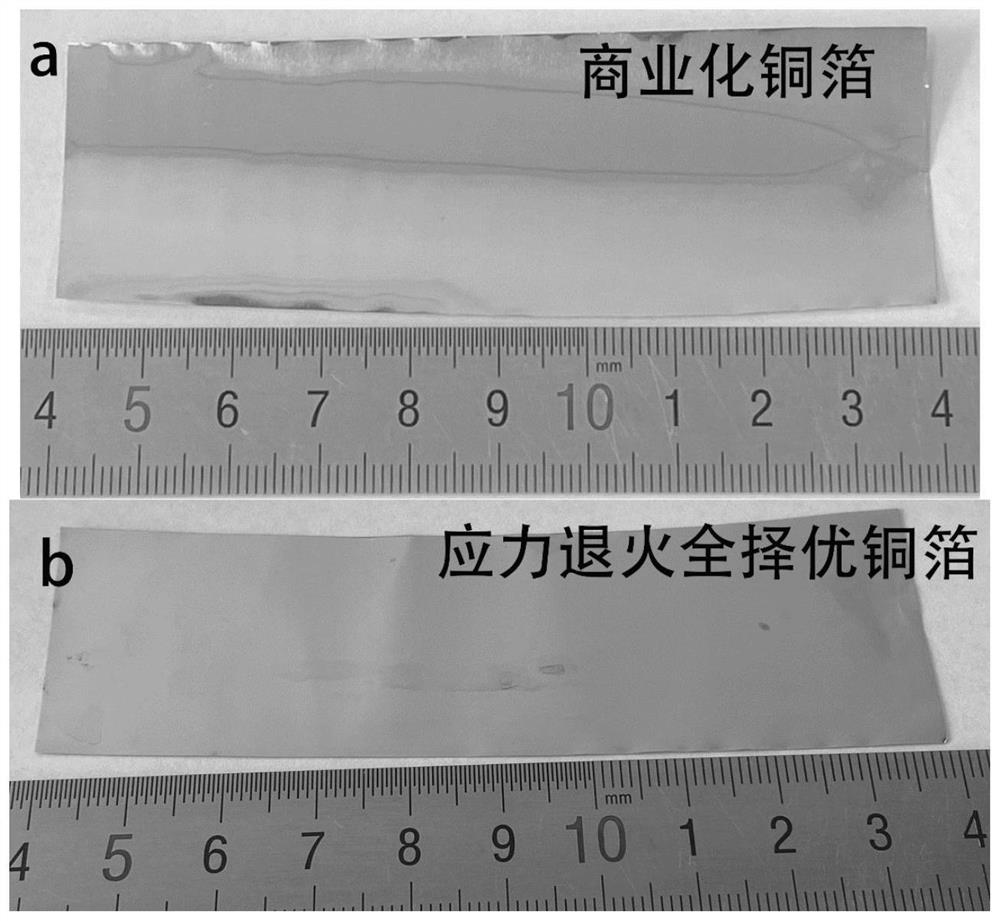

Embodiment 1

[0051] 1. The commercial copper foil substrate of 30 microns (thickness) is rolled 5 times under a pressure of 200 MPa using a roller press. The speed of the roller is 0.5m / s, and then the stress-introduced copper foil is annealed at 150°C, 300°C and 450°C for 4h, the heating rate is 5°C / min, and 5% H 2 and 95% Ar atmosphere. Driven by the residual thermal stress, the commercialized copper foil was successfully transformed into a copper foil with only a single (100) crystal plane orientation. This experimental phenomenon has been successfully proved by XRD test, and it is the first time that this kind of metal substrate that undergoes a single crystal plane orientation transition at a low temperature (relative to the melting point of copper, 1073°C) has been discovered. figure 1 It is the XRD spectrum of the copper foil annealed at different temperatures in this embodiment. It can be seen that with the increase of the annealing temperature, the copper foil gradually transform...

Embodiment 2

[0057] 1. A commercial zinc foil substrate with a thickness of 30 microns is first rolled 5 times under a pressure of 200 MPa using a pair of rollers. The speed of the roller is 0.5m / s, and then the surface oxide layer is removed by simple chemical polishing using dilute sulfuric acid, and the annealing atmosphere is Ar / H 2 In a mixed atmosphere, the heating rate was 10°C / min, and the annealing was performed at 415°C for 12 hours to obtain a 0002 zinc foil with a single preferred crystal plane orientation. Figure 8 In this example, the XRD patterns of the commercialized zinc foil and the fully preferred single crystal plane orientation zinc foil indicate that the single crystal plane orientation Zn foil was successfully obtained at 415°C.

[0058] 2. The Zn||Zn symmetric battery assembled with fully preferred single-crystal plane orientation zinc foil and commercial zinc foil was tested for cycle life, and the electrolyte used was 2mol ZnSO 4 , glass fiber as a separator, as...

Embodiment 3

[0060] 1. The commercial Ni foil with a thickness of 30 microns was first rolled 5 times with a roller press, and the pressure and speed were 500MPa and 0.4m / s, respectively. After annealing, use dilute sulfuric acid to remove the oxide layer on the metal surface. Then anneal at 1000°C for 4h, the annealing atmosphere is Ar / H 2 Mixed atmosphere, the heating rate is 10°C / min. The corresponding crystal orientation changes were investigated. Figure 10 is the XRD pattern of the corresponding Ni foil, indicating that after annealing at 1000 ° C, the exposed crystal plane will change significantly, and it is found that the Ni foil after stress annealing has a high degree of preference (90%) in the (200) crystal plane orientation.

[0061] 2. The untreated commercial nickel foil and the Ni(200) preferred crystal plane orientation nickel foil prepared by stress annealing at 1000°C were subjected to LSV test in 3mol KCl aqueous solution. The test was to use Pt as the counter electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com