Moisture-absorption-resistant inorganic binder powder for casting, activation solution and use method

An inorganic binder and anti-hygroscopic technology, which can be used in casting molding equipment, molds, cores, etc., can solve the problems of inconvenient transportation, long production cycle, poor fluidity of sand mixture, etc., to improve strength and anti-hygroscopicity. The effect of improving the anti-hygroscopicity and improving the process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

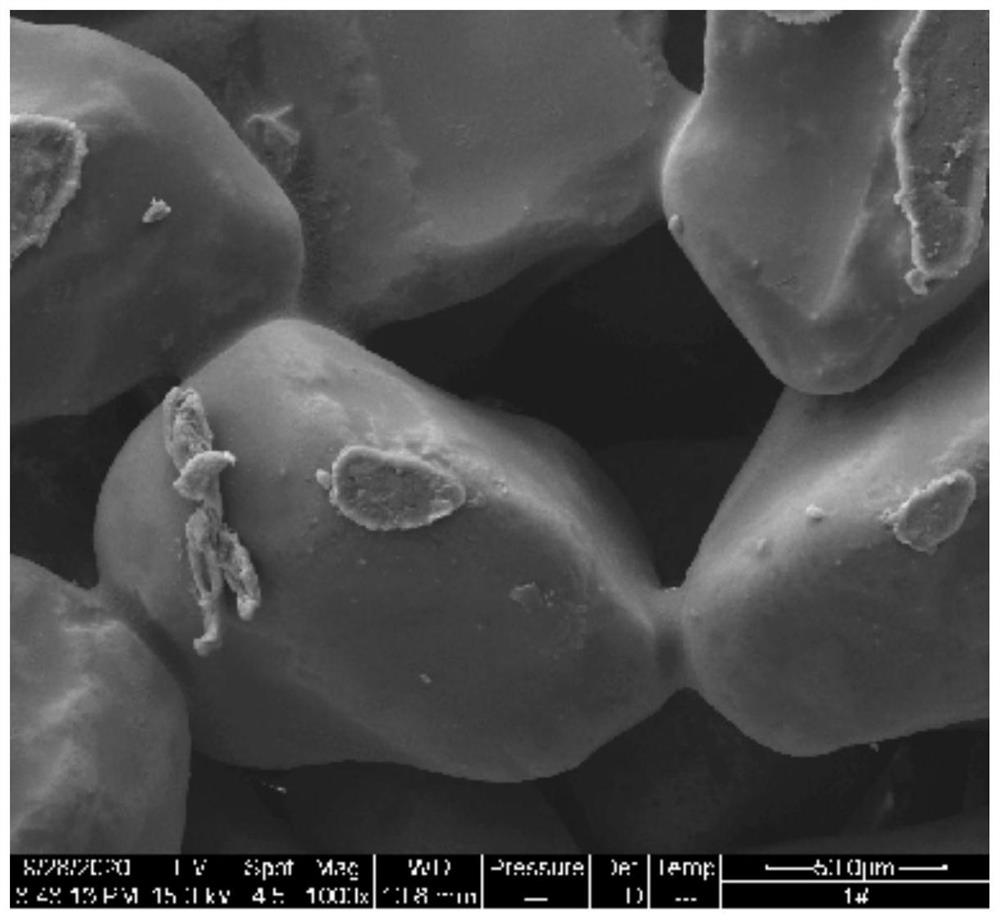

Image

Examples

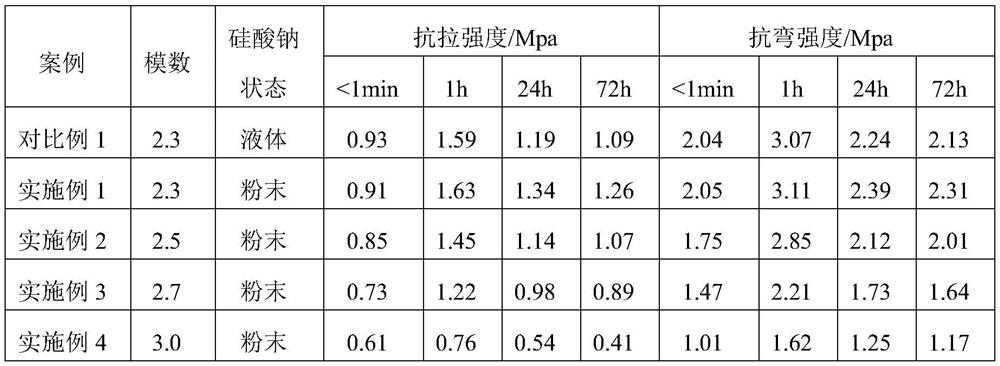

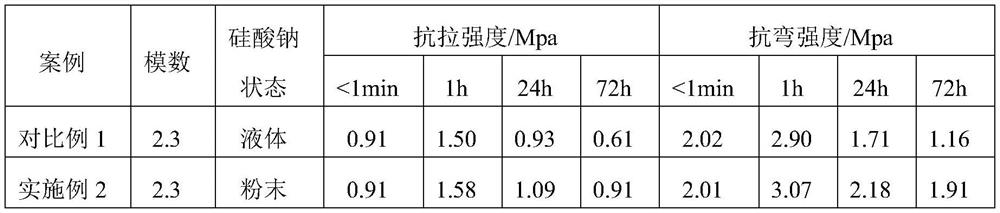

Embodiment 1

[0072] Embodiment 1: specifically include the following steps

[0073] (1), preparation composition A:

[0074] Weigh 16g of industrial grade instant sodium silicate powder with modulus 2.3, 2g of dodecylbenzenesulfonate and 2g of potassium feldspar and put them into a sand mixer for mixing, preferably using a vane sand mixer, at room temperature, Mix the materials for 1 min until the mixture is fully uniform, then stop stirring and turn off the mixer to obtain the composition A;

[0075] (2), preparation composition B:

[0076] Weigh 16g of microsilica, 2g of borax, 2g of sodium polymetaphosphate, 4g of maltodextrin, 2g of barium sulfate, 2g of lithium hydroxide monohydrate and 2g of nano-silicon dioxide. , Maltodextrin and barium sulfate are put into a sand mixer for mixing, preferably a blade type sand mixer, at room temperature, mix the materials for 0.5-3min, until fully mixed, then add lithium hydroxide, and continue mixing for 0.5- 3min, until fully mixed, finally ad...

Embodiment 2

[0083] Embodiment 2: specifically comprise the following steps:

[0084] (1), preparation composition A:

[0085] Weigh 16g of industrial grade instant sodium silicate powder with modulus 2.5, 2g of dodecylbenzene sulfonate and 2g of potassium feldspar and put them into a sand mixer for mixing, preferably a blade-type sand mixer, at room temperature, Mix the materials for 1 min until the mixture is fully uniform, then stop stirring and turn off the mixer to obtain the composition A;

[0086] (2), preparation composition B:

[0087] Weigh 16g of microsilica, 2g of borax, 2g of sodium polymetaphosphate, 4g of maltodextrin, 2g of barium sulfate, 2g of lithium hydroxide monohydrate and 2g of nano-silicon dioxide. , Maltodextrin and barium sulfate are put into a sand mixer for mixing, preferably a blade type sand mixer, at room temperature, mix the materials for 0.5-3min, until fully mixed, then add lithium hydroxide, and continue mixing for 0.5- 3min, until fully mixed, finally...

Embodiment 3

[0094] Embodiment 3: specifically comprise the following steps:

[0095] (1), preparation composition A:

[0096] Weigh 16g of industrial grade instant sodium silicate powder with modulus 2.7, 2g of dodecylbenzene sulfonate and 2g of potassium feldspar and put them into a sand mixer for mixing, preferably a blade-type sand mixer, at room temperature, Mix the materials for 1 min until the mixture is fully uniform, then stop stirring and turn off the mixer to obtain the composition A;

[0097] (2), preparation composition B:

[0098] Weigh 16g of microsilica, 2g of borax, 2g of sodium polymetaphosphate, 4g of maltodextrin, 2g of barium sulfate, 2g of lithium hydroxide monohydrate and 2g of nano-silicon dioxide. , Maltodextrin and barium sulfate are put into a sand mixer for mixing, preferably a blade type sand mixer, at room temperature, mix the materials for 0.5-3min, until fully mixed, then add lithium hydroxide, and continue mixing for 0.5- 3min, until fully mixed, finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com