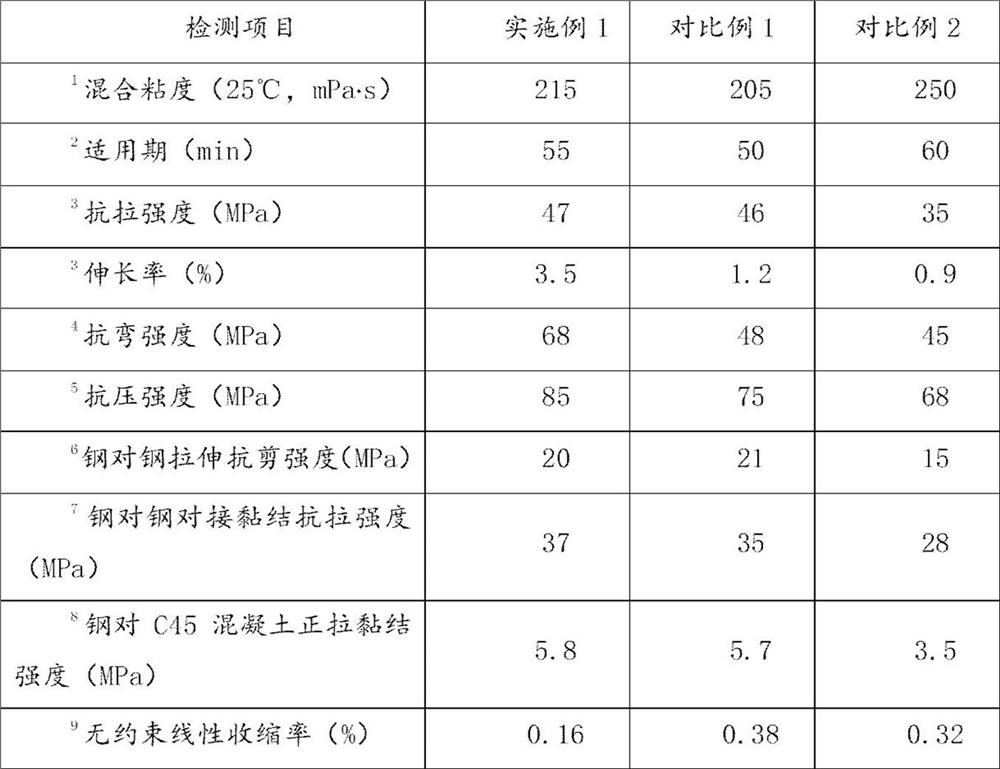

Solvent-free low-shrinkage epoxy pouring adhesive for repairing concrete cracks and preparation method of solvent-free low-shrinkage epoxy pouring adhesive

A low-shrinkage, crack-repairing technology, applied in the field of pouring glue, can solve the problems of low mechanical strength, achieve high bond strength, improve toughness, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a solvent-free low-shrinkage type concrete crack repair epoxy pouring glue, and the preparation method is specifically as follows:

The preparation method of A component comprises the following steps:

S11. Preheat 100-120 parts of epoxy resin at 60° C. for 6-8 hours.

[0028] S12, at normal temperature, add 100-120 parts of epoxy resin and 10-15 parts of diluent in proportion to the reaction kettle, stir for 15-20 minutes, and keep the vacuum degree at -0.095--0.100MPa.

[0029] S13, add 0.5-1 part of defoaming agent and 0.2-0.5 part of leveling agent in proportion, stir for 10-15 minutes, and keep the vacuum degree at -0.095--0.100MPa.

[0030] S14. Clean the stirring teeth and the wall of the kettle, continue stirring for 5 to 6 minutes, keep the vacuum degree at -0.095 to -0.100 MPa, and then discharge the materials for separate packaging.

[0031] The preparation method of B component comprises the following steps:

Preparation of modified n...

Embodiment 1

Component A consists of the following components by weight:

50 parts of 618 bisphenol A type epoxy resin, 10 parts of 6002 bisphenol A type epoxy resin, 30 parts of 170 bisphenol F type epoxy resin, 10 parts of 165 bisphenol F type epoxy resin, 5 alkyl glycidyl ethers part, 8 parts of butanediol glycidyl ether, 0.5 part of defoamer, and 0.2 part of leveling agent.

[0042] Component B consists of the following components by weight:

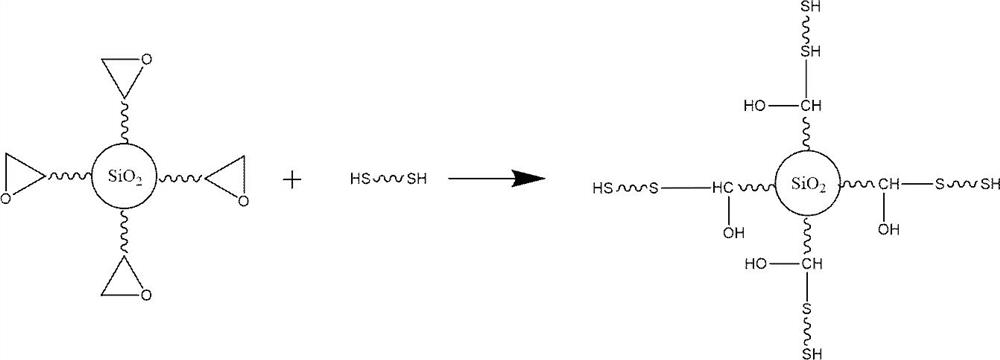

①Preparation of modified nano-silica powder

10g of KH560 was added to 190g of absolute ethanol in the flask, and acetic acid was added dropwise to adjust the pH value of the solution to about 4. Stir at room temperature for 5 h. After stirring, add 12 g of SiO to the 2 Put it into the stirred solution, ultrasonically dispersed for 30 min, stirred at 75 °C for 4 h, cooled and centrifuged, and dried at 140 °C for 24 h to obtain the modified nano-silica powder containing epoxy groups on the surface.

[0043] ②Preparation of modified toughening a...

Embodiment 2

[0047] Component B consists of the following components by weight:

[0048] ②Preparation of modified toughening agent

[0049] 40 parts of N-aminoethylpiperazine, 40 parts of isophorone diamine, 10 parts of D230 polyetheramine, 10 parts of 651 low viscosity polyamide, 8 parts of modified toughening agent, 6 parts of accelerator, KH550 silane coupler 2 parts of the joint agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com