Iron-silver co-doped biochar with high adsorption capacity and preparation method of iron-silver co-doped biochar

A technology of co-doping and high adsorption, applied in the fields of biofuels, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of uneven load, large consumption of chemical reagents, uneven materials, etc. Resource utilization, low consumption of chemical reagents and small amount of iron leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Preparation of iron-silver co-doped biochar (FSHC) and iron-doped biochar (FHC)

[0037] 1. Preparation method of FSHC

[0038] After drying the Li Shihe plant body to constant weight to obtain Li Shihe biomass, then co-doping with iron and silver, operate according to the following steps:

[0039] (1) Take 50 mL of ultrapure water to prepare a mixed solution system: under stirring conditions, add 3 mL of concentrated H into the beaker in turn 3 PO4 (concentration 85wt%), 3gFe (NO 3 ) 3 ·9H 2 O, 0.3g AgNO 3 , placed in an ultrasonic cleaner for 10min to disperse the solution uniformly;

[0040] (2) get 3g dried to constant weight of Li's wort biomass (that is, the sample obtained after Li's wort plant body is dried), pulverize to the size below 1cm, then add 100ml of polytetrafluoroethylene together with the solution obtained in step (1) In the lining of the reaction kettle, ultrasonicate for 10min to make the mixing uniform;

[0041] (3) The reaction ...

Embodiment 2

[0049] Embodiment 2, FSHC and FHC product detection

[0050] The FSHC and FHC prepared in Example 1 were detected.

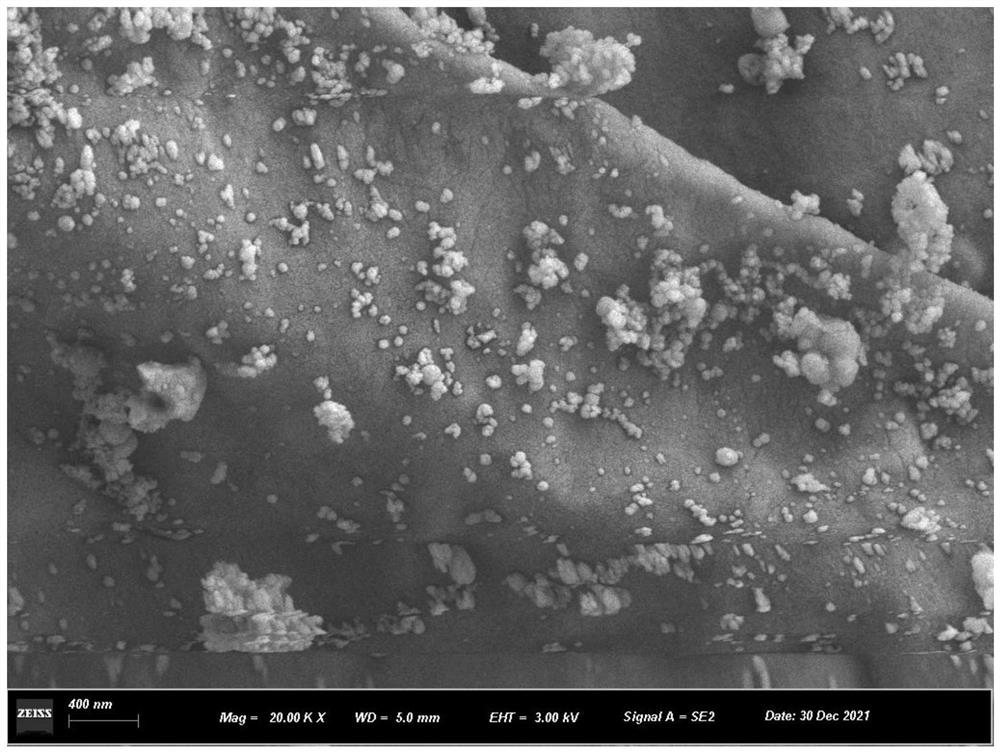

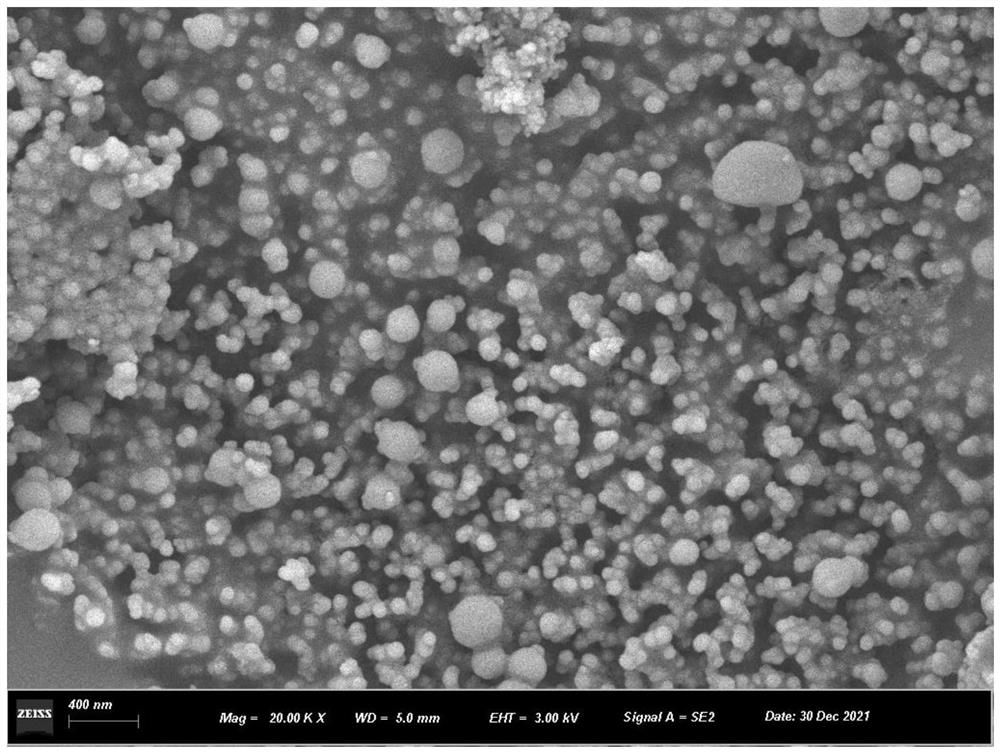

[0051] figure 1 and figure 2 The SEM images of FSHC and FHC are respectively. The Fe particles in FHC are successfully loaded on the hydrothermal carbon, but the particle size is large and it is easy to aggregate into agglomerates. Compared with FHC, due to the introduction of Ag, the Fe loading of FSHC is uniformly distributed on the hydrothermal carbon, with a particle size of about 100 nm and is not easy to aggregate into agglomerates.

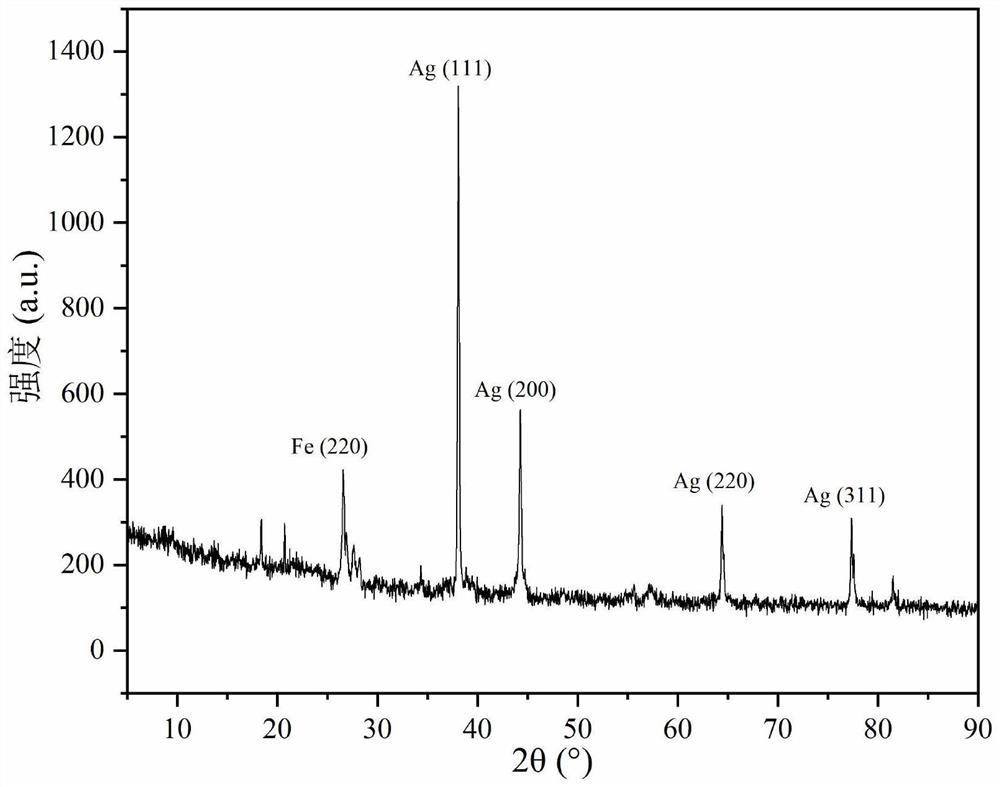

[0052] The XRD scan results of FSHC are as follows image 3 As shown, 38.1°, 44.3°, 64.4°, and 77.4° correspond to the Ag(111), Ag(200), Ag(220), and Ag(311) crystal planes respectively (JCPDS No. 04-783), indicating that the silver particles are in the Biochar has been successfully doped with biochar during the preparation process; 34.3°, 57.8° correspond to Fe 3 O 4 (220) and (511) crystal planes (JCPDS No.19-0629), ...

Embodiment 3

[0055] Example 3, Cr(VI) removal experiment

[0056] Get the FSHC, FHC prepared in Example 1 for the treatment of Cr (VI)-containing waste water:

[0057] Take 0.04 g of the prepared FSHC and FHC materials and add them to a polyvinyl chloride centrifuge tube, and then add 40 mL of simulated wastewater containing 100 mg / LCr(VI) and a pH of 2, and quickly transfer them to an air-bath constant temperature oscillator. Adsorption at 25°C for 24h. The results showed that the adsorption capacities of FSHC and FHC materials for 100 mg / L Cr(VI) wastewater were 85.41 mg / g and 65.64 mg / g, respectively, and the leaching amounts of Fe in the solution after 24 h of reaction were 0.25 mg / L and 0.05 mg / L, respectively. , the Fe leaching amount of FSHC meets the drinking water standard (GB 5749-2006) of 0.3mg / L.

[0058] The initial pH is one of the important leading factors for the removal efficiency of Cr(VI) from water, which affects the degree of protonation of functional groups on the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com