Accurate metal cluster-based composite catalyst as well as preparation method and application thereof

A technology of composite catalysts and metal clusters, applied in the field of organic chemistry, can solve problems such as limited applications, frequent occurrence of extreme weather, and exacerbated instability of the climate system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

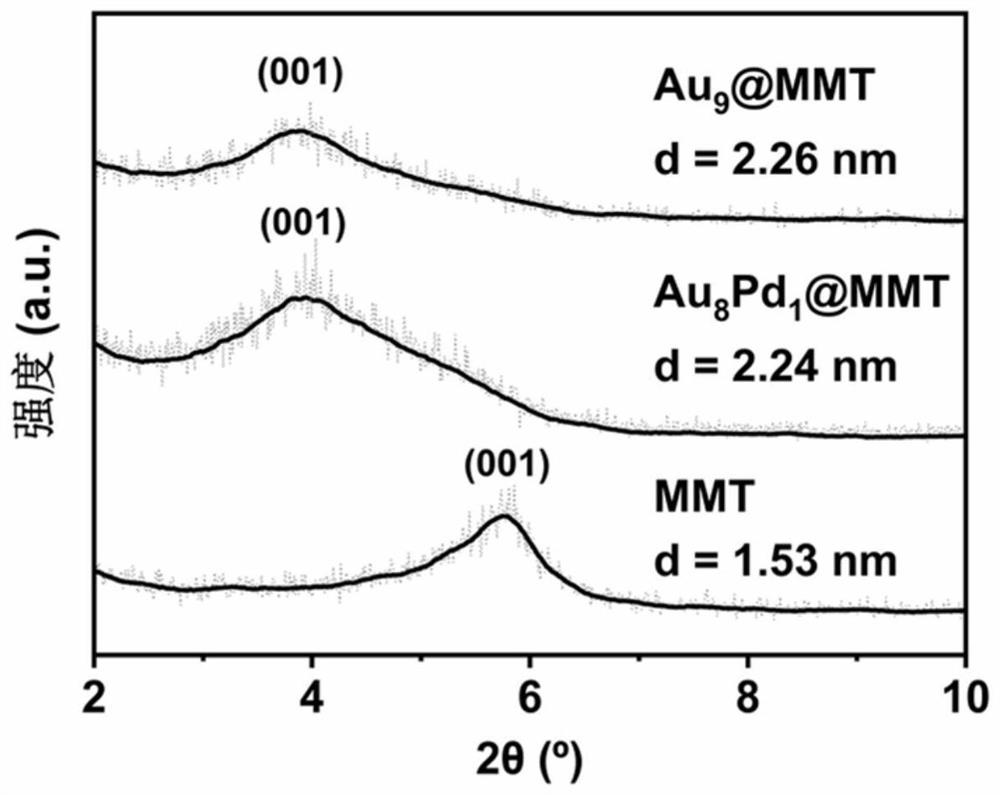

[0037] The technical scheme is that the number of atoms is 9, 25 and 44, and the metal type is gold, silver, palladium, platinum and metal nanoclusters of alloys of the above metals are composite catalysts with active centers, and the specific preparation method includes the following steps:

[0038] ①Ligand coordination and multi-distribution metal sol molding: prepare a solution of metal precursors or a mixed solution of metal precursors with a mass fraction of 1% to 10%. One or more of the above-mentioned metal salt solutions or suspension solutions are added to the flask, and under vigorous stirring, organic phosphine ligands or thiol ligands with a mass of 0.5 to 10 times the molar weight of the metal salt are added to the liquid phase. middle;

[0039] ②NaBH 4 Reduction: prepare sodium borohydride (NaBH) with a mass fraction of 0.1% to 5% 4 )The solution. The above NaBH 4 The solution (0.1-10 ml) is added dropwise or rapidly to the solution in step ①, and after conti...

Embodiment 1

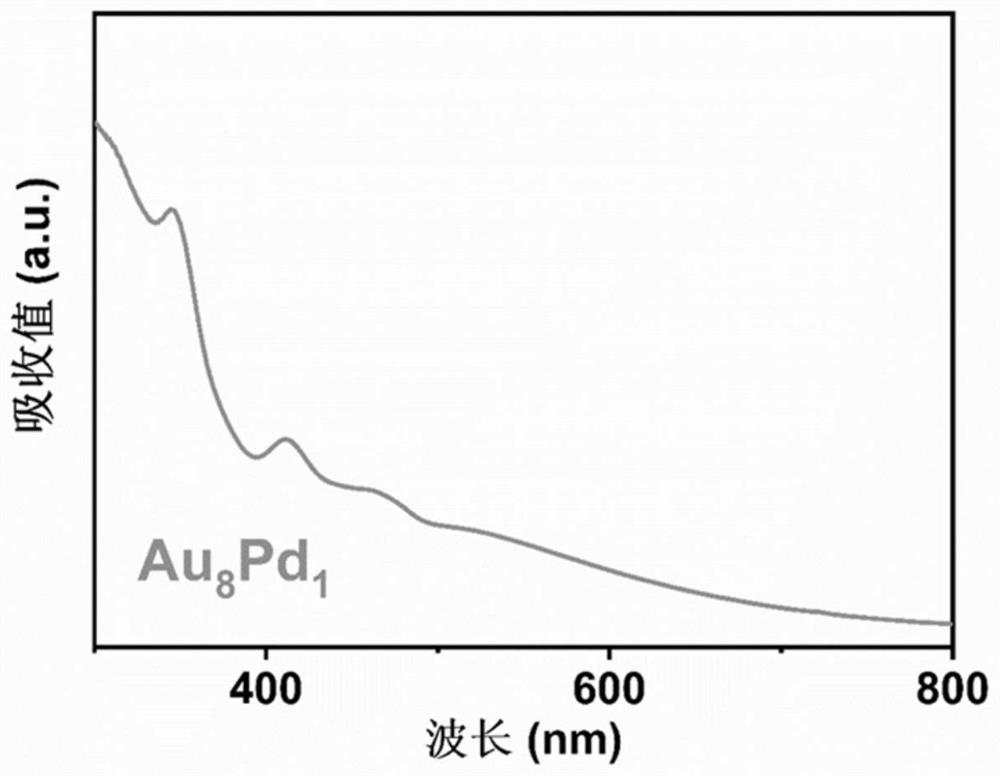

[0046] Dissolve 1600 mg of tetrachloroauric acid in 40 ml of dichloromethane, stir to obtain a yellow transparent solution, add 2350 mg of triphenylphosphine and continue stirring for 30 minutes to obtain a colorless solution. Then, 500 mg of tetrakistriphenylphosphine palladium was dissolved in 40 ml of dichloromethane, and a dark red transparent solution was obtained after stirring. The above two solutions were added to a 200-mL flask, and after stirring for 10 minutes, a dark purple solution was obtained. 76 mg NaBH 4 Dissolve in 20 mL of ethanol solution and add this solution dropwise to the flask. After 30 minutes of reaction, the product was evaporated to dryness using a rotary evaporator to obtain a black solid. The solid was extracted with 40 mL of ethanol and filtered through celite, and the filtrate was evaporated to dryness in vacuo. The resulting black solid was washed three times with ether, extracted with dichloromethane and dried by vacuum evaporation to give...

Embodiment 2

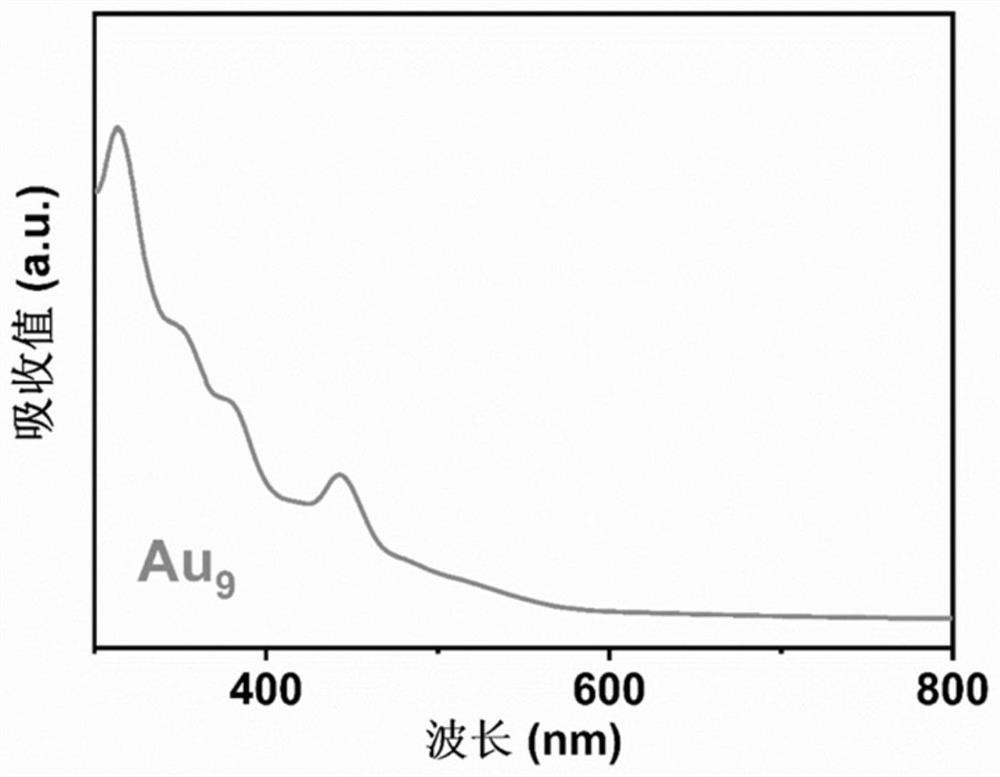

[0050] Dissolve 1600 mg of tetrachloroauric acid in 80 ml of dichloromethane, stir to obtain a yellow transparent solution, add 2350 mg of triphenylphosphine, and continue stirring for 30 minutes to obtain a colorless solution. Then, silver nitrate was added in a 1.5-fold molar amount of tetrachloroauric acid. After stirring for 60 minutes, a colorless solution was obtained, which was transferred to a 200 mL flask. 76 mg NaBH 4 Dissolve in 20 mL of ethanol solution and add this solution dropwise to the flask. After 30 minutes of reaction, the product was evaporated to dryness using a rotary evaporator to give a black solid. The solid was extracted with 40 mL of ethanol and filtered through celite, and the filtrate was evaporated to dryness in vacuo. The resulting black solid was washed three times with ether, extracted with dichloromethane and dried by vacuum evaporation to give a black solid. Through ultraviolet-visible spectroscopy (UV-Vis) test, the obtained metal nanoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com