Recycling and regenerating method of waste lithium cobalt oxide positive electrode material

A cathode material, the technology of old lithium cobalt oxide, which is applied in the field of lithium ion battery material recycling and reuse, can solve the problems that the electrochemical performance of regenerated LiCoO2 needs to be improved, the final product of the lithium mixing step is uneven, and the sintering time is long, and the regeneration process can be achieved. Mild and controllable conditions, stable high voltage, structural stability, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for recycling and regenerating waste lithium cobalt oxide cathode material, the specific steps are as follows:

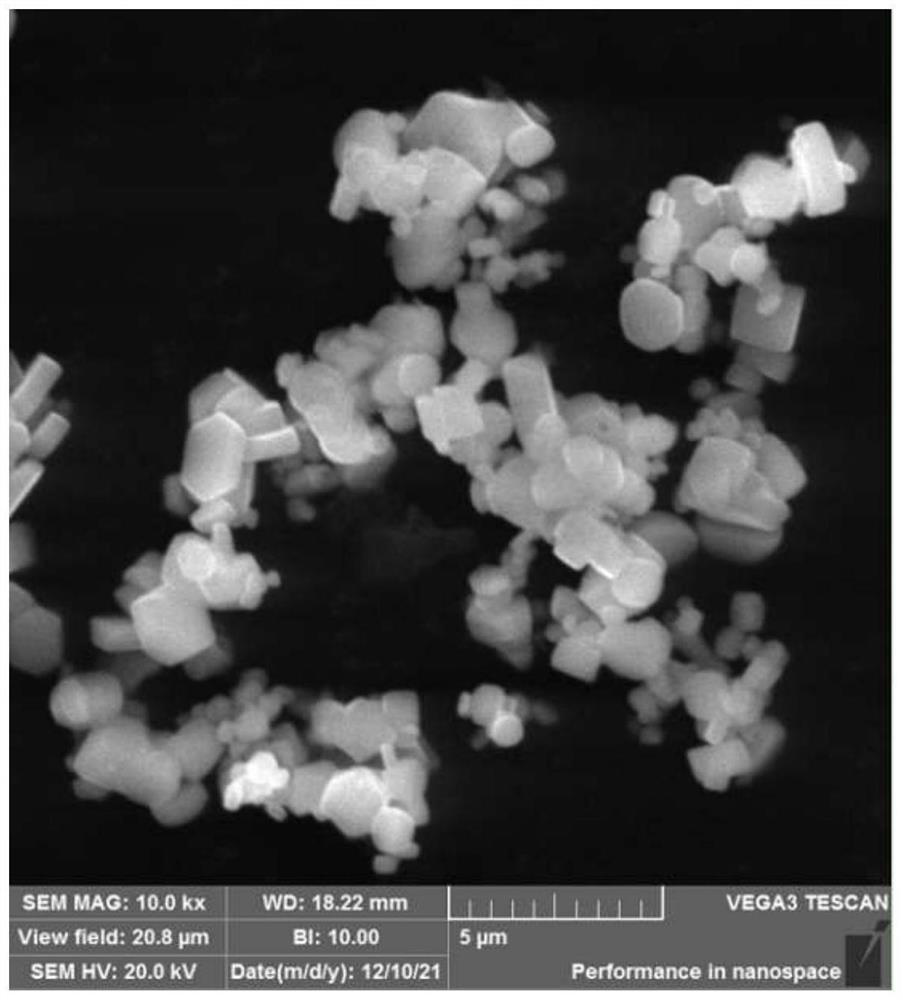

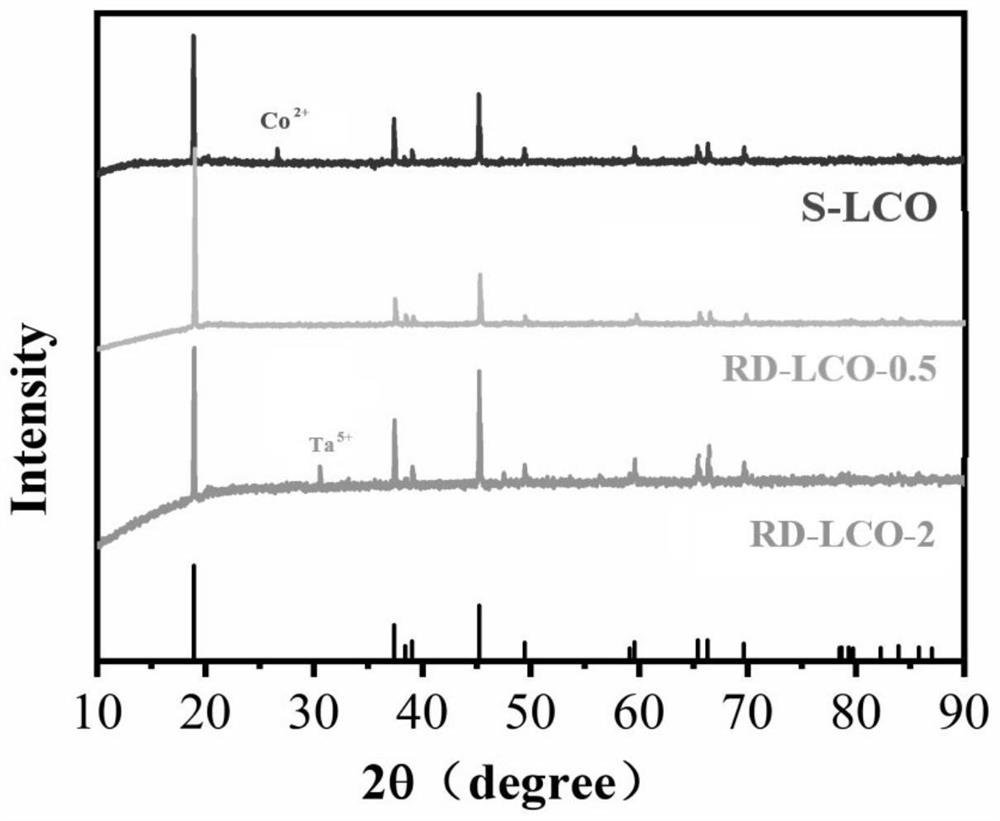

[0027] S1. According to the solid-liquid ratio of the waste lithium cobalt oxide battery positive electrode sheet and ethylene glycol as 8g / L, put the waste lithium cobalt oxide battery positive electrode sheet in ethylene glycol, and then put the mixture under oxygen, and the oxygen flow rate is 0.06 L / min, ultrasonic-assisted leaching, ultrasonic power is 120W, ultrasonic temperature is 50°C, ultrasonic time is 3h, after the leaching treatment is completed, pass through a 300-mesh sieve, separate the positive electrode material from the aluminum foil, and put the undersize in a vacuum drying oven for 120 Placed at ℃ for 8h, the waste lithium cobalt oxide cathode powder was obtained and recorded as S-LCO;

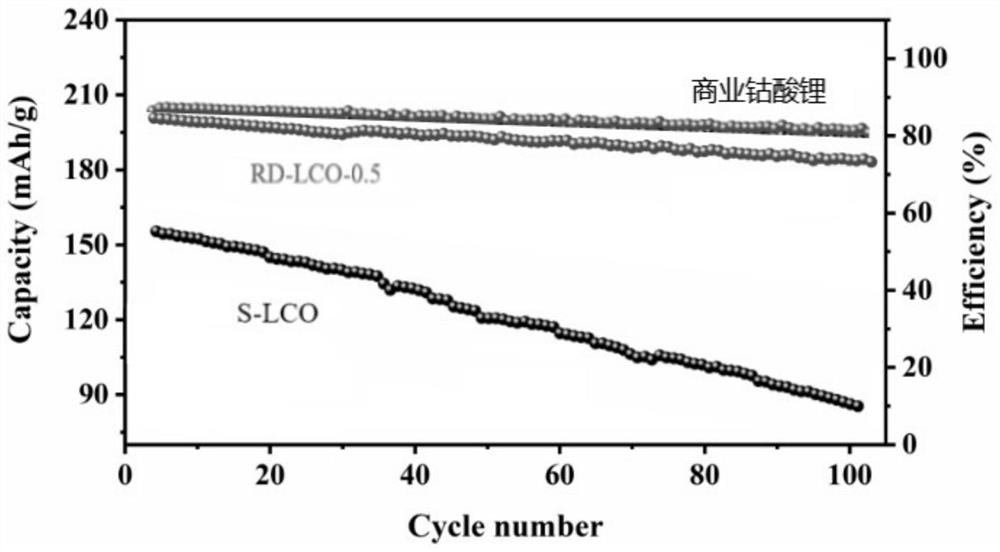

[0028] S2. Put lithium isopropoxide and waste lithium cobalt oxide cathode powder S-LCO in ethanol, the mass ratio of lithium isopropoxide and w...

Embodiment 2

[0031] A method for recycling and regenerating waste lithium cobalt oxide cathode material, the specific steps are as follows:

[0032]S1. According to the solid-liquid ratio of the waste lithium cobalt oxide battery positive electrode sheet and ethylene glycol as 10g / L, put the waste lithium cobalt oxide battery positive electrode sheet in ethylene glycol, and then put the mixture under oxygen, and the oxygen flow rate is 0.1 L / min, ultrasonic-assisted leaching, ultrasonic power is 100W, ultrasonic temperature is 40°C, ultrasonic time is 3h, after the leaching treatment is completed, pass through a 300-mesh sieve, separate the positive electrode material from the aluminum foil, and put the material under the sieve in a vacuum drying oven for 120 Placed at ℃ for 8h, the waste lithium cobalt oxide cathode powder was obtained and recorded as S-LCO;

[0033] S2. Put lithium isopropoxide and waste lithium cobalt oxide cathode powder S-LCO in ethanol, the mass ratio of lithium isop...

Embodiment 3

[0036] A method for recycling and regenerating waste lithium cobalt oxide cathode material, the specific steps are as follows:

[0037] S1. According to the solid-liquid ratio of the waste lithium cobalt oxide battery positive electrode sheet and ethylene glycol as 9g / L, put the waste lithium cobalt oxide battery positive electrode sheet in ethylene glycol, and then put the mixture under oxygen, and the oxygen flow rate is 0.08 L / min, ultrasonic-assisted leaching, ultrasonic power is 80W, ultrasonic temperature is 30°C, ultrasonic time is 4h, after the leaching treatment is completed, pass through a 300-mesh sieve, separate the positive electrode material from the aluminum foil, and put the undersize in a vacuum drying oven for 120 Placed at ℃ for 8h, the waste lithium cobalt oxide cathode powder was obtained and recorded as S-LCO;

[0038] S2. Put lithium isopropoxide and waste lithium cobalt oxide cathode powder S-LCO in ethanol, the mass ratio of lithium isopropoxide and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com