Method for extracting, separating and purifying glabridin from glycyrrhiza glabra residues

A technology of licorice glabra residue and glabridin, applied in chemical instruments and methods, organic chemistry, lignin derivatives, etc., to achieve high extraction rate, high purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

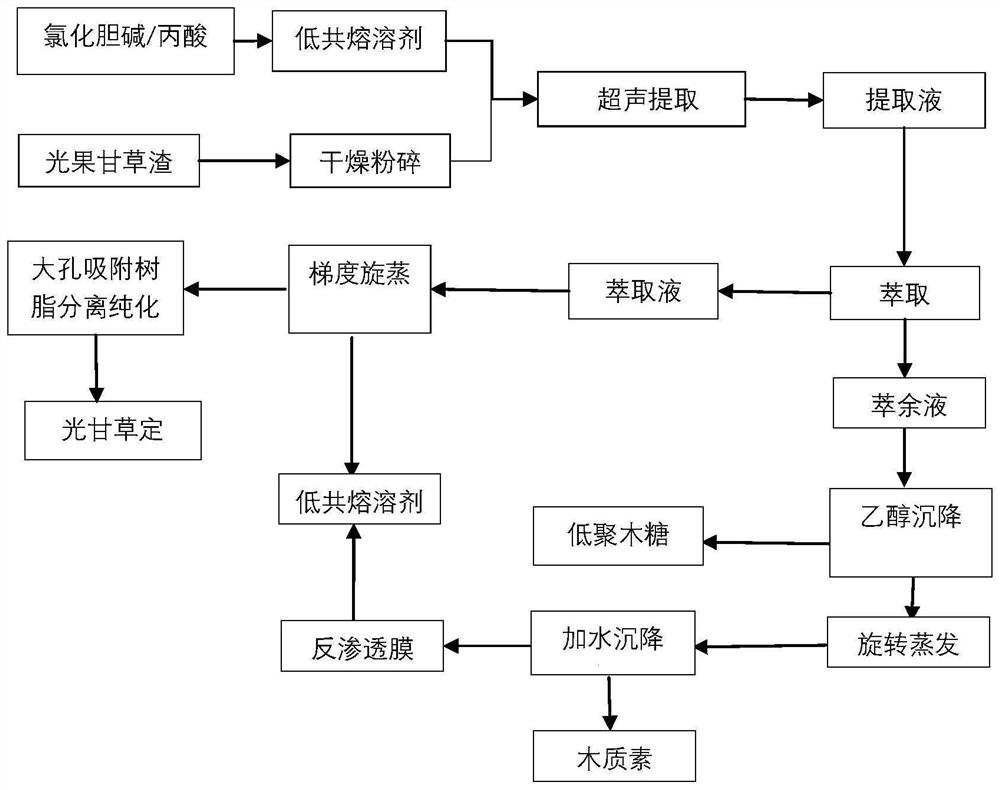

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Extraction of Glycyrrhizin

[0033] (1) preparation of extraction solvent: choline chloride and propionic acid are stirred at room temperature for 0.5h in a water-bath magnetic stirring pot in a molar ratio of 1:2-4 to obtain a transparent and uniform deep eutectic solvent, which is 10% by volume, Deionized water was added to 20% and 30% to configure the extraction solvent.

[0034] (2) Extraction: take 2 kg of Glycyrrhiza glabra slag, dry at 60°C for 12 hours, pulverize, and pass through an 80-mesh sieve to obtain Glycyrrhiza glabra slag powder. Take 2g of Glycyrrhiza glabra slag powder respectively in a 100mL conical flask, add the extraction solvent prepared in step (1) according to the material-to-liquid ratio of 1:20, 1:30 or 1:40 mg / mL, and divide the extraction solvent into 1-3 times Add, 30-80 ℃ ultrasonic-assisted extraction for 0.5-2h, suction filtration to obtain the glabridin crude extract, HPLC to determine the content of glabridin, calculate th...

Embodiment 2

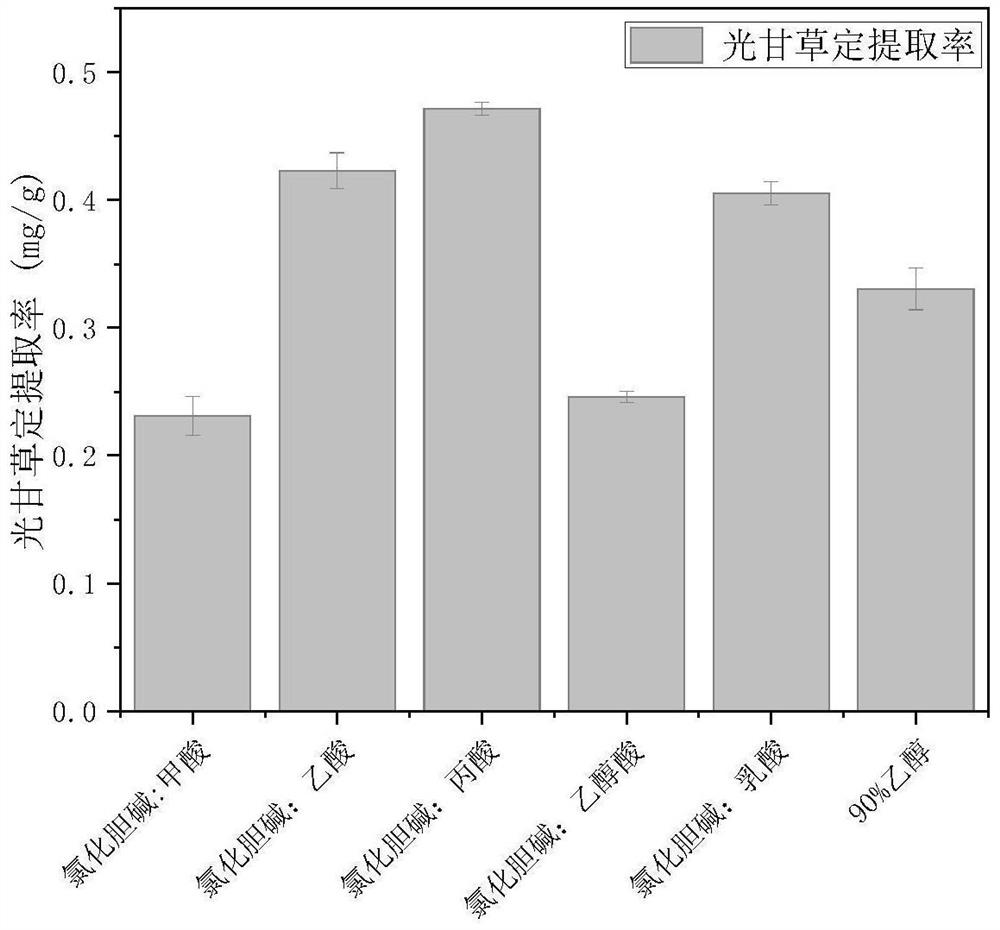

[0035] Example 2: Screening of extraction solvents and extraction conditions

[0036] (1) preparation of extraction solvent: choline chloride is respectively mixed with formic acid, acetic acid, glycolic acid, lactic acid and propionic acid in a molar ratio of 1:4, stirring at room temperature for 30min to obtain a transparent and uniform deep eutectic solvent, by volume The percentage is 20%, and deionized water is added to configure it as an extraction solvent. Another 90% ethanol was prepared as the extraction solvent.

[0037](2) Extraction: take 2 kg of Glycyrrhiza glabra slag, dry at 60°C for 12 hours, pulverize, and pass through an 80-mesh sieve to obtain Glycyrrhiza glabra slag powder. Take 2g of Glycyrrhiza glabra slag powder in a 100mL conical flask, add extraction solvent according to the material-to-liquid ratio of 1:20 mg / mL, extract at 60 °C for 1 h, and filter with suction to obtain a crude extract of Glycyrrhiza glabra. The content of Glycyrrhizin is determine...

Embodiment 3

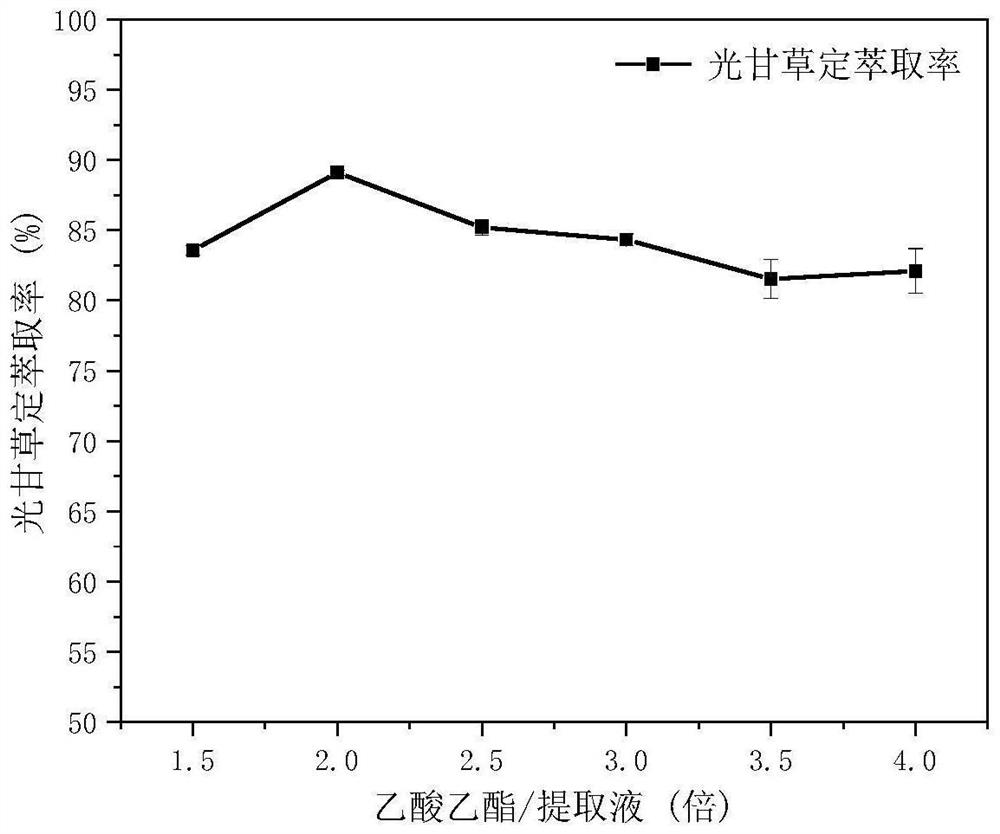

[0040] Embodiment 3: the screening of extractant and the amount of extractant

[0041] (1) preparation of extraction solvent: choline chloride and propionic acid are stirred at room temperature for 0.5h in a water-bath magnetic stirring pot in a molar ratio of 1:4 to obtain a transparent and uniform deep eutectic solvent, which is 10% by volume and deionized Water, configured as extraction solvent.

[0042] (2) Extraction: take 2 kg of Glycyrrhiza glabra slag, dry at 60°C for 12 hours, pulverize, and pass through an 80-mesh sieve to obtain Glycyrrhiza glabra slag powder. Take 10g of Glycyrrhiza glabra slag powder in a 500mL conical flask, add the extraction solvent prepared in step (1) according to the material-to-liquid ratio of 1:20mg / mL, 40 ℃ ultrasonic-assisted extraction for 1h, and suction filtration to obtain the crude extract of Glycyrrhiza liquid, the extraction rate of glabridin was 0.49 mg / g.

[0043] (3) extraction: get petroleum ether, cyclohexane, ethyl acetate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com