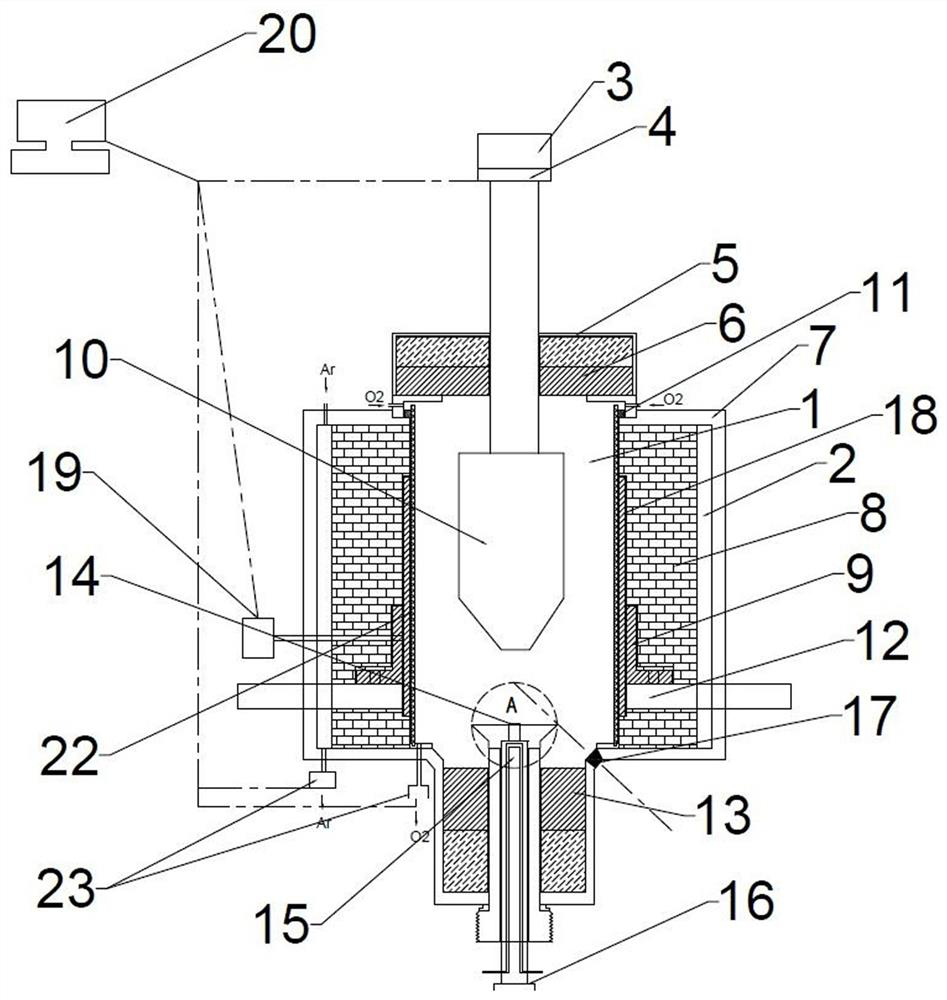

Growth device and growth method of iridium-free zone-melting gallium oxide crystal

A growth device, gallium oxide technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problem of not meeting the needs of large-scale and large-scale industries, affecting the crystal growth process and crystal quality, and high maintenance costs , to achieve the effect of no macroscopic defects, elimination of instability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

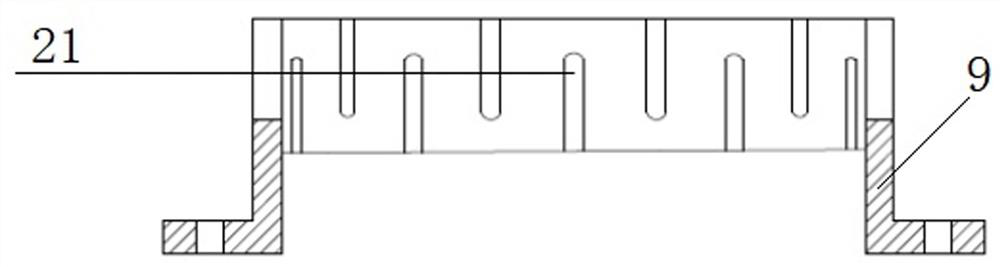

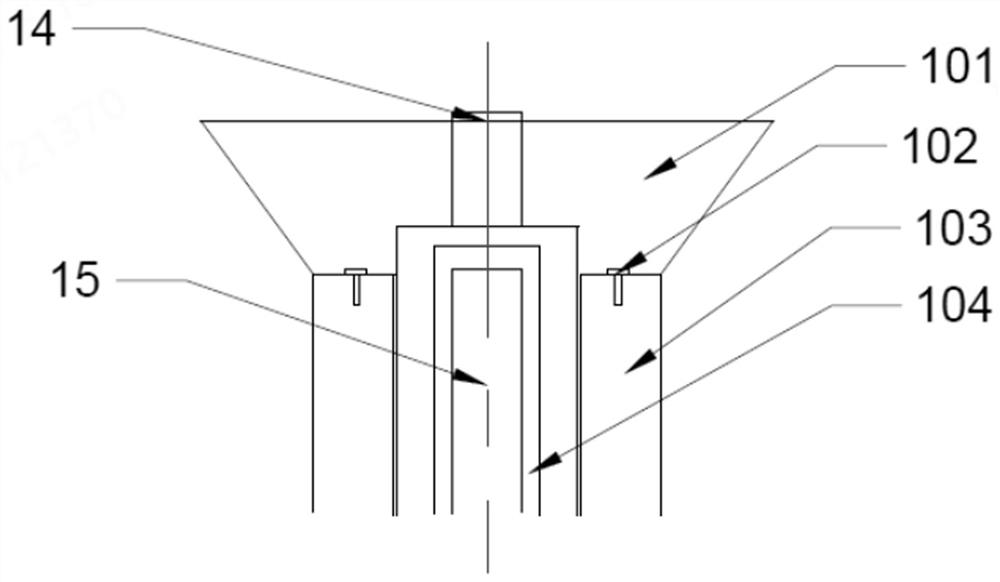

Method used

Image

Examples

Embodiment 1

[0068] The present embodiment provides a method for growing a gallium oxide crystal by melting in an iridium-free zone, comprising the following steps:

[0069] 1) Rod preparation: 5N grade gallium oxide powder or dopant mixed with doping elements is pressed into powder rods with molds and hydraulic devices, and sintered at 1300 °C in a vertical rotating sintering furnace for 32 hours to obtain external 2) Rod processing: Use diamond wire cutting or laser cutting to trim the rod to obtain a raw rod with a diameter of 50mm and a length of 100mm. The alloy fixing parts are fixed, and there are rigid connecting joints on the fixing parts.

[0070] 3) Material rod installation: Lift the first rotating pulling device to the top of the furnace, fix the prepared gallium oxide material rod on the first rotating pulling device through a latch or a holding connection, and calibrate the material rod with a laser calibrator. Straight, lower the first rotary pulling device at a speed of 2...

Embodiment 2

[0075] The present embodiment provides a method for growing a gallium oxide crystal by melting in an iridium-free zone, comprising the following steps:

[0076] 1) Preparation of material rod: directly use the pure gallium oxide material rod obtained as patent CN202210047059.0.

[0077] 2) Material bar processing: Use diamond wire cutting or laser cutting to trim the material bar to obtain a raw material bar with a diameter of 100mm and a length of 200mm. Rigid connection connector.

[0078] 3) Material rod installation: Lift the first rotating pulling device to the top of the furnace, fix the prepared gallium oxide material rod on the first rotating pulling device through a latch or a holding connection, and calibrate the material rod with a laser calibrator. Straight, lower the first rotary pulling device at a speed of 2000mm / h to the highest temperature setting that has been calibrated, and install the zirconia fiber insulation material and quartz cylinder on the upper par...

Embodiment 3

[0083] The present embodiment provides a method for growing a gallium oxide crystal by melting in an iridium-free zone, comprising the following steps:

[0084] 1) Preparation of material rod: directly use the Si-doped material rod obtained as patent CN202210047059.0;

[0085] 2) Material bar processing: Use diamond wire cutting or laser cutting to trim the material bar to obtain a raw material bar with a diameter of 50mm and a length of 200mm. Rigid connection connector.

[0086] 3) Material rod installation: Lift the first rotating pulling device to the top of the furnace, fix the prepared gallium oxide material rod on the first rotating pulling device through a latch or a holding connection, and calibrate the material rod with a laser calibrator. Straight, lower the first rotary pulling device at a speed of 2000mm / h to the highest temperature setting that has been calibrated, and install the zirconia fiber insulation material and quartz cylinder on the upper part of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com