Method for synthesizing and purifying electronic-grade hydrogen peroxide

A purification method, hydrogen peroxide technology, applied in chemical instruments and methods, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, electrodes, etc., can solve the problems of low added value of hydrogen, etc. The effect of low production cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

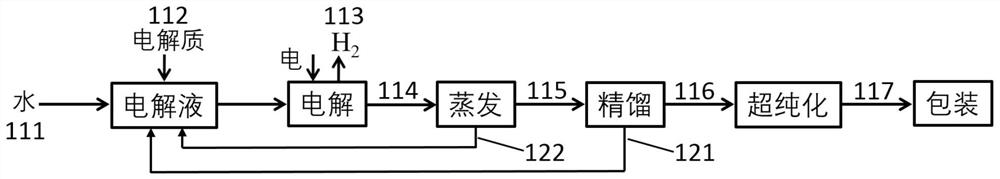

[0026] Embodiment 1: adopt the electronic grade hydrogen peroxide synthesis and purification method of bismuth vanadate method

[0027] In this embodiment, the electrolyzers, evaporators and rectification towers in the main production equipment are provided with ordinary high-purity fusible polytetrafluoroethylene PFA as the inner lining to avoid contamination of hydrogen peroxide and ensure stability. Among them, the electrolytic cell adopts doped bismuth vanadate single crystal as the anode material, nickel-based alloy as the cathode material, and the cathode and the anode are separated by a proton exchange membrane. The evaporator adopts a falling film evaporator, and the rectification column adopts a primary rectification column. The ultra-purification step is distillation, and the lining of the evaporator and the rectifying tower is made of special ultra-pure electronic grade PFA material. The applied bias voltage is 2.7V, and the current density during electrolysis is 0...

Embodiment 2

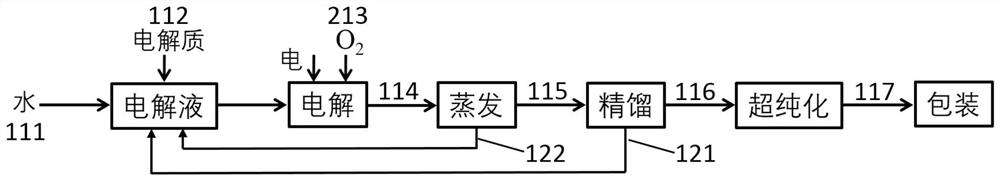

[0031] Embodiment 2: adopt the electronic grade hydrogen peroxide synthesis and purification method that the bismuth vanadate method and the oxygen cathode reduction method are combined

[0032] Based on the structure of the main production equipment in Example 1, in this example, the cathode of the electrolysis cell was changed to a carbon-based material, that is, graphite / carbon black / polytetrafluoroethylene composite, and the applied bias voltage was reduced to 2.5V, and the current during electrolysis Density is 0.25A / cm 2 .

[0033] like figure 2 As shown, on the basis of the flow process of Example 1, the electrolytic solution flows through the electrolytic cell to generate an electrolysis reaction, and the high-purity oxygen 213 of the raw material that feeds into the cathode generates an oxygen reduction reaction to obtain hydrogen peroxide, and the anode generates a two-electron water oxidation reaction and also obtains. Hydrogen oxide; when the hydrogen peroxide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com