Hard gold cyanide-free electroforming solution as well as preparation method and electroforming process thereof

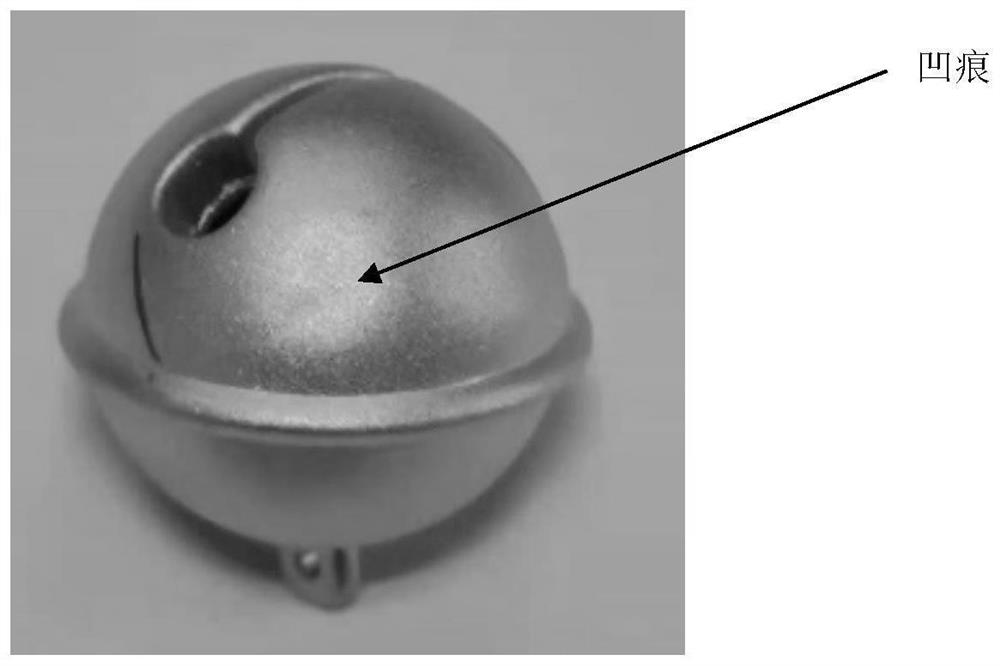

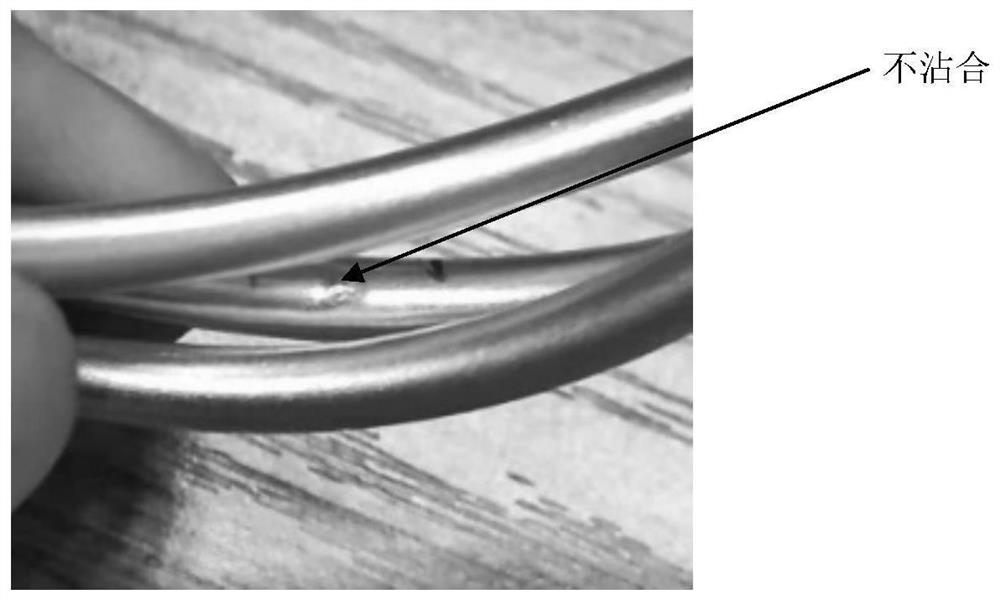

A technology of electroforming liquid and gold, applied in electroforming, electrolysis process, etc., can solve the problems of difficult to guarantee the thickness uniformity of electroforming layer, poor weldability of electroforming layer, unstable current efficiency, etc. Strong, good flatness, the effect of eliminating pinholes and pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The formula of hard gold cyanide-free electroforming fluid is as follows:

[0045] 8g / L gold sodium sulfite, 70g / L sodium sulfite, 30g / L dipotassium hydrogen phosphate, 0.5g / L EDTA-2Na, 0.05g / L sodium tellurite, 0.05g / L pyridinesulfonic acid, 1g / L saccharin and 0.01g / L sodium dibutylnaphthalene sulfonate

[0046] The preparation method is as follows:

[0047](1) Place the weighed 70 g of anhydrous sodium sulfite and 30 g of dipotassium hydrogen phosphate into a beaker, add an appropriate amount of deionized water and stir to a paste.

[0048] (2) Weigh 0.5 g of EDTA-2Na into the beaker, and stir evenly.

[0049] (3) Pipette an appropriate amount of prepared sodium gold sulfite solution into a beaker, and stir until all solids in the solution are dissolved.

[0050] (4) Mix 0.05 g of sodium tellurite, 0.05 g of pyridine sulfonic acid, 1 g of saccharin, and 0.01 g of sodium dibutylnaphthalene sulfonate with warm water at about 50° C., and pour into the beaker after ful...

Embodiment 2

[0055] The formula of electroforming fluid is as follows:

[0056] 10g / L gold sodium sulfite, 100g / L sodium sulfite, 50g / L dipotassium hydrogen phosphate, 2g / L EDTA-2Na, 1g / L sodium tellurite, 1g / L pyridinesulfonic acid, 5g / L saccharin and 5g / L Sodium dibutylnaphthalene sulfonate

[0057] The preparation method is as follows:

[0058] (1) Place the weighed 100 g of anhydrous sodium sulfite and 50 g of dipotassium hydrogen phosphate in a beaker, add an appropriate amount of deionized water and stir to a paste.

[0059] (2) Weigh 2g of EDTA-2Na into the beaker and stir evenly.

[0060] (3) Pipette an appropriate amount of prepared sodium gold sulfite solution into a beaker, and stir until all solids in the solution are dissolved.

[0061] (4) Mix 2 g of sodium tellurite, 2 g of pyridine sulfonic acid, 5 g of saccharin and 5 g of sodium dibutylnaphthalene sulfonate with warm water at about 50°C, fully dissolve and cool, and pour into the beaker.

[0062] (5) Adjust the pH of ...

Embodiment 3

[0066] The formula of electroforming fluid is as follows:

[0067] 10g / L gold sodium sulfite, 100g / L sodium sulfite, 40g / L dipotassium hydrogen phosphate, 1g / L EDTA-2Na, 0.2g / L sodium tellurite, 0.2g / L pyridinesulfonic acid, 1g / L saccharin and 2g / L sodium dibutylnaphthalene sulfonate

[0068] The preparation method is as follows:

[0069] (1) Place 100 g of anhydrous sodium sulfite and 40 g of dipotassium hydrogen phosphate weighed into a beaker, add an appropriate amount of deionized water and stir until it becomes a paste.

[0070] (2) Weigh 1 g of EDTA-2Na into the beaker and stir evenly.

[0071] (3) Pipette an appropriate amount of prepared sodium gold sulfite solution into a beaker, and stir until all solids in the solution are dissolved.

[0072] (4) Mix 0.2 g of sodium telluride, 0.2 g of pyridine sulfonic acid, 1 g of saccharin and 2 g of sodium dibutylnaphthalene sulfonate with warm water at about 50°C, and pour into the beaker after fully dissolving and cooling....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com