Ultraviolet photosensitive corrosion-resistant and wear-resistant filler, preparation method thereof and application of ultraviolet photosensitive corrosion-resistant and wear-resistant filler in coating

An anti-corrosion and wear-resistant, ultraviolet light technology, applied in the field of coatings, can solve the problems of poor anti-corrosion and wear resistance, poor bonding performance between fillers and coating matrix, poor filler dispersion, etc., to enhance anti-corrosion performance and wear resistance, and improve dispersion , to solve the effect of uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In the preparation process of the ultraviolet photosensitive composite filler, the red phosphorus and the photosensitive filler undergo a hydrothermal reaction to form one or more phosphorus atom-based colloidal products, which can promote phosphorus passivation of the metal substrate. Due to the small size of the phosphorus atom-based colloid component, it is easy to disperse into the coating system, and can be evenly distributed on the surface of the metal substrate, which promotes phosphorus passivation of the metal substrate.

[0065] The invention also provides the application of a functional ultraviolet photosensitive filler in the coating, comprising the following steps:

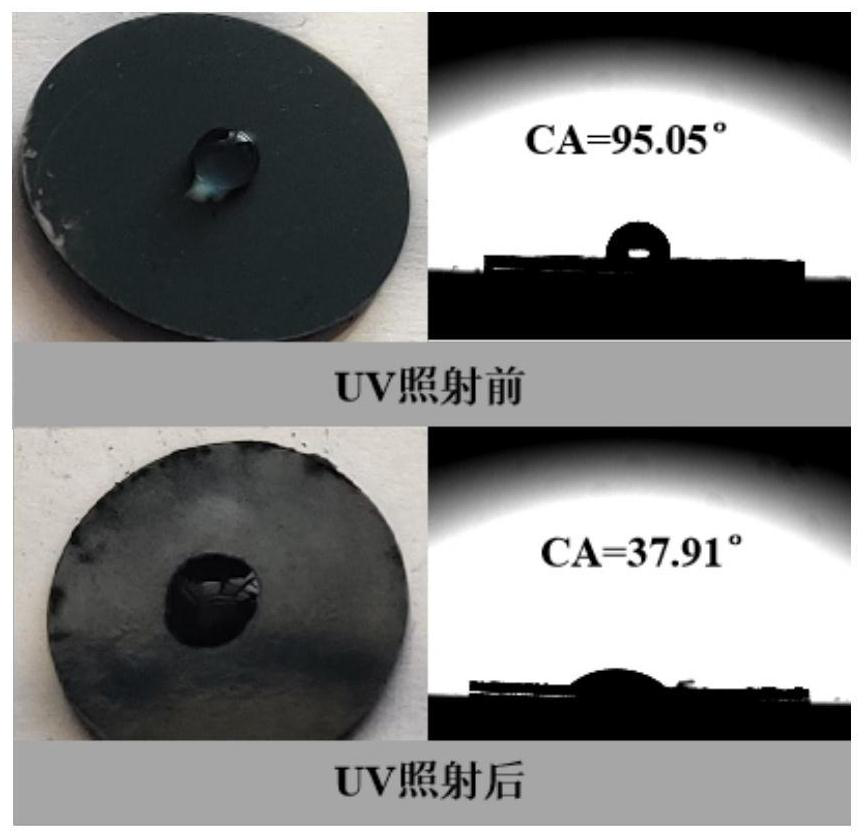

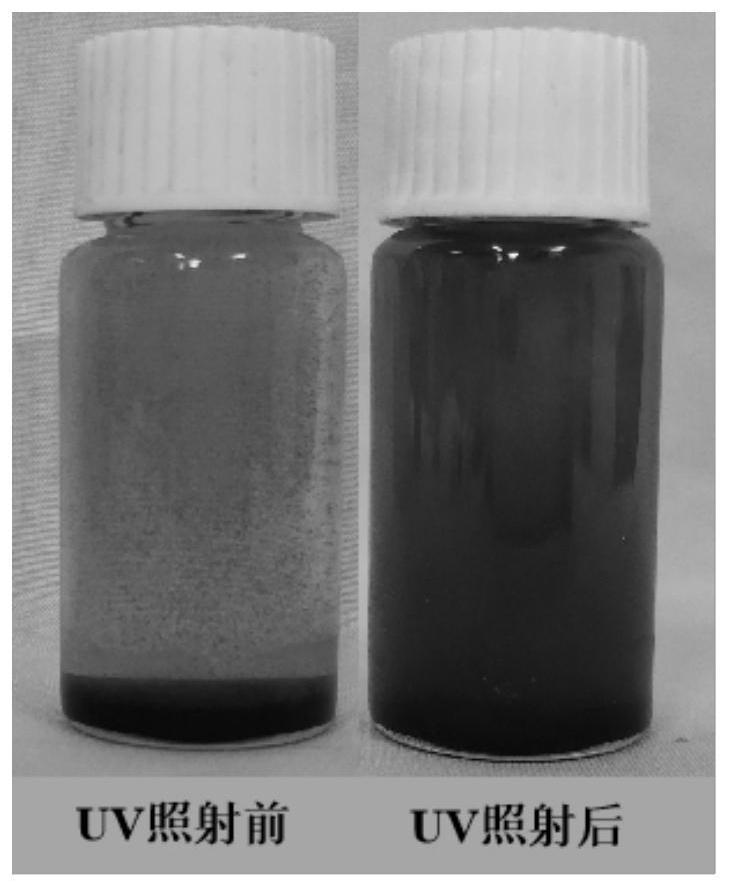

[0066] (1) After the functional photosensitive composite filler is exposed to ultraviolet light, it is de-dispersed into a mixed solution of de-ethanol and ethyl acetate to obtain a filler dispersion.

[0067] (2) Disperse epoxy resin, phenolic resin, fluorocarbon resin, polyurea resin, aliphat...

Embodiment 1

[0071] (1) Pretreatment of metal surface:

[0072] Use 240-mesh and 400-mesh sandpaper to polish the metal surface in turn, then put it into ethanol solution for ultrasonic cleaning, or treat the metal substrate with a high-pressure water jet with a water pressure greater than 20 MPa to remove dust, grease, etc. on the surface of the metal substrate Impurities, of which the concentration of the ethanol solution is 75%, are taken out and dried for later use.

[0073] (2) Preparation of UV photosensitive composite filler:

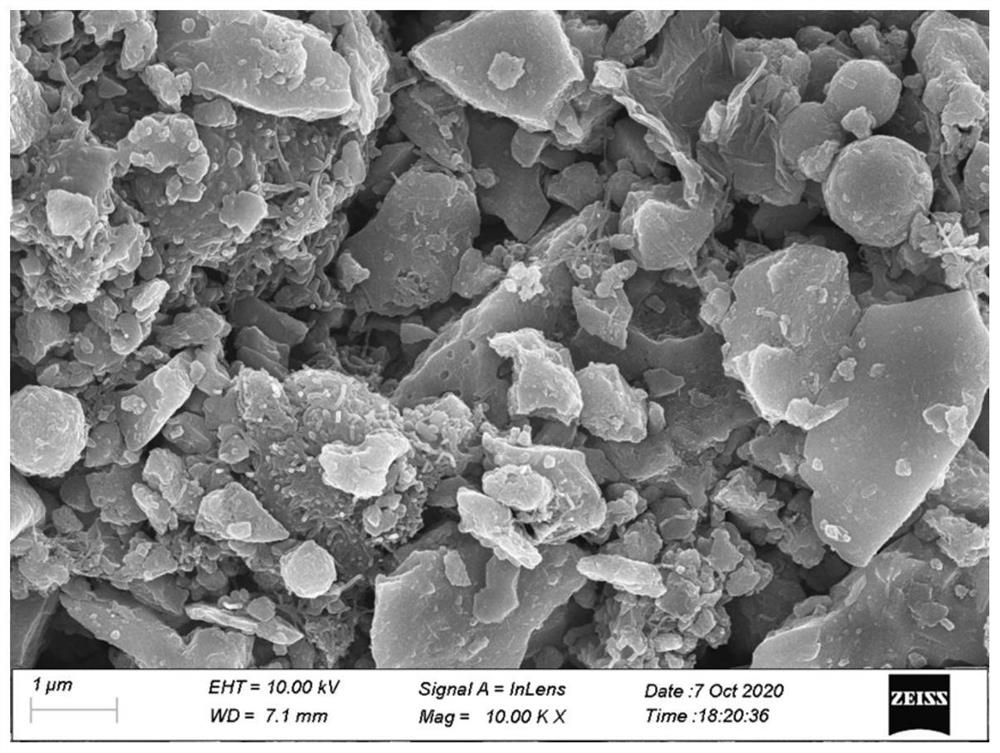

[0074] 150 parts of titanium dioxide, 100 parts of reducing titanium dioxide, 20 parts of zinc oxide, 100 parts of nickel oxide and 80 parts of tin oxide are dispersed in 50 parts of deionized water to obtain a photosensitive filler mixed solution. Disperse 3 parts of graphene oxide, 5 parts of molybdenum disulfide, 2 parts of montmorillonite, 50 parts of carbon nanotubes, 20 parts of carbon fibers and 40 parts of glass fibers into 150 parts of anhydrous eth...

Embodiment 2

[0086] (1) Pretreatment of metal surface:

[0087] Use 600-mesh and 800-mesh sandpaper to polish the metal surface in turn, then put it into ethanol solution for ultrasonic cleaning, or treat the metal substrate with a high-pressure water jet with a water pressure greater than 15 MPa to remove dust, grease, etc. on the surface of the metal substrate Impurities, of which the concentration of the ethanol solution is 75%, are taken out and dried for later use.

[0088] (2) Preparation of UV photosensitive composite filler:

[0089] 250 parts of titanium dioxide, 50 parts of reducing titanium dioxide, 150 parts of cadmium sulfide and 150 parts of tungsten oxide are dispersed in 50 parts of deionized water to obtain a photosensitive filler mixed solution. Disperse 50 parts of graphene, 30 parts of hexagonal boron nitride, 20 parts of mica, 10 parts of flake carbonyl iron and 15 parts of rod-shaped ceria into 150 parts of anhydrous ethanol solution to obtain a mixed solution of aux...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com