CrAlN/CrAlSiN/TaC composite coating with low friction coefficient and high wear resistance and preparation method of CrAlN/CrAlSiN/TaC composite coating

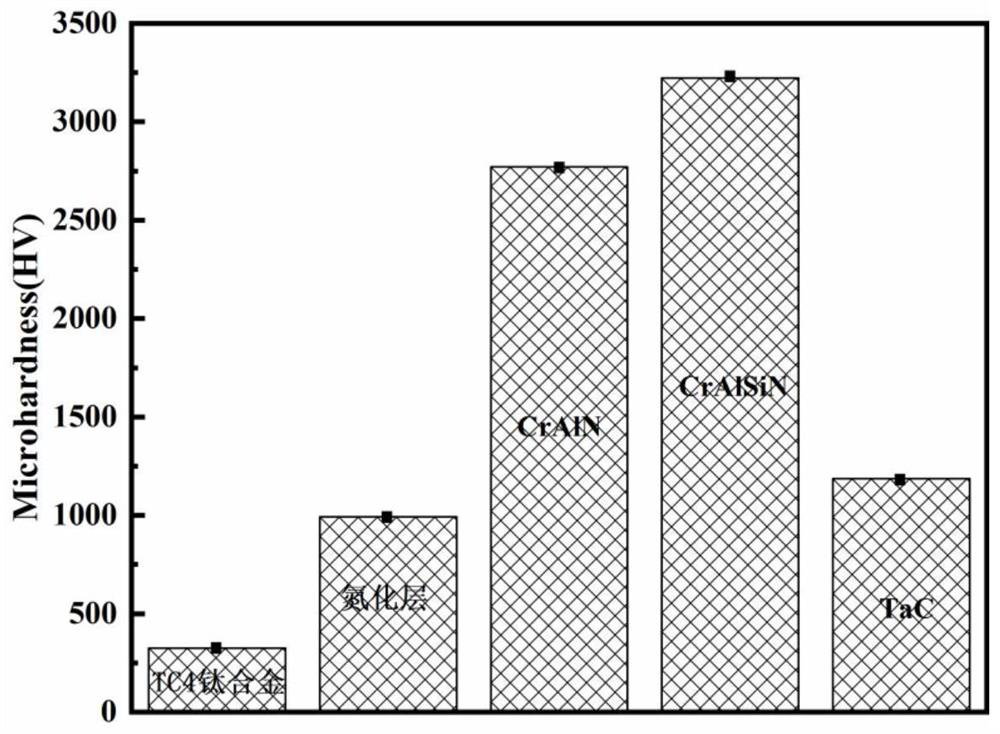

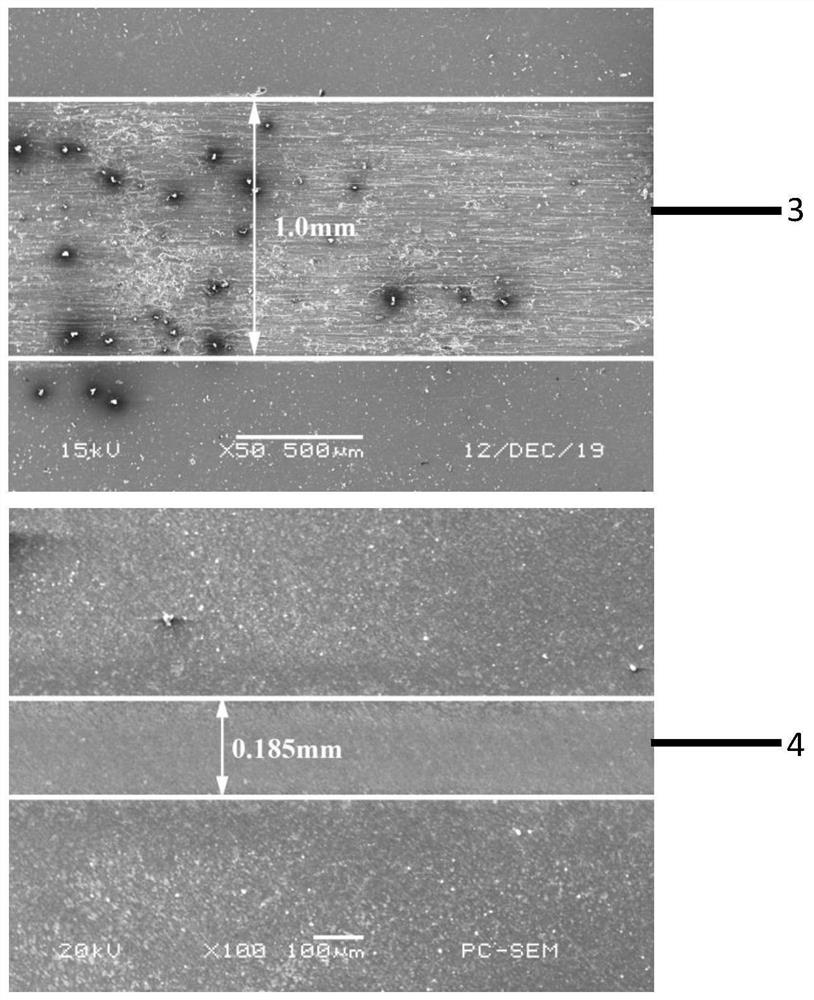

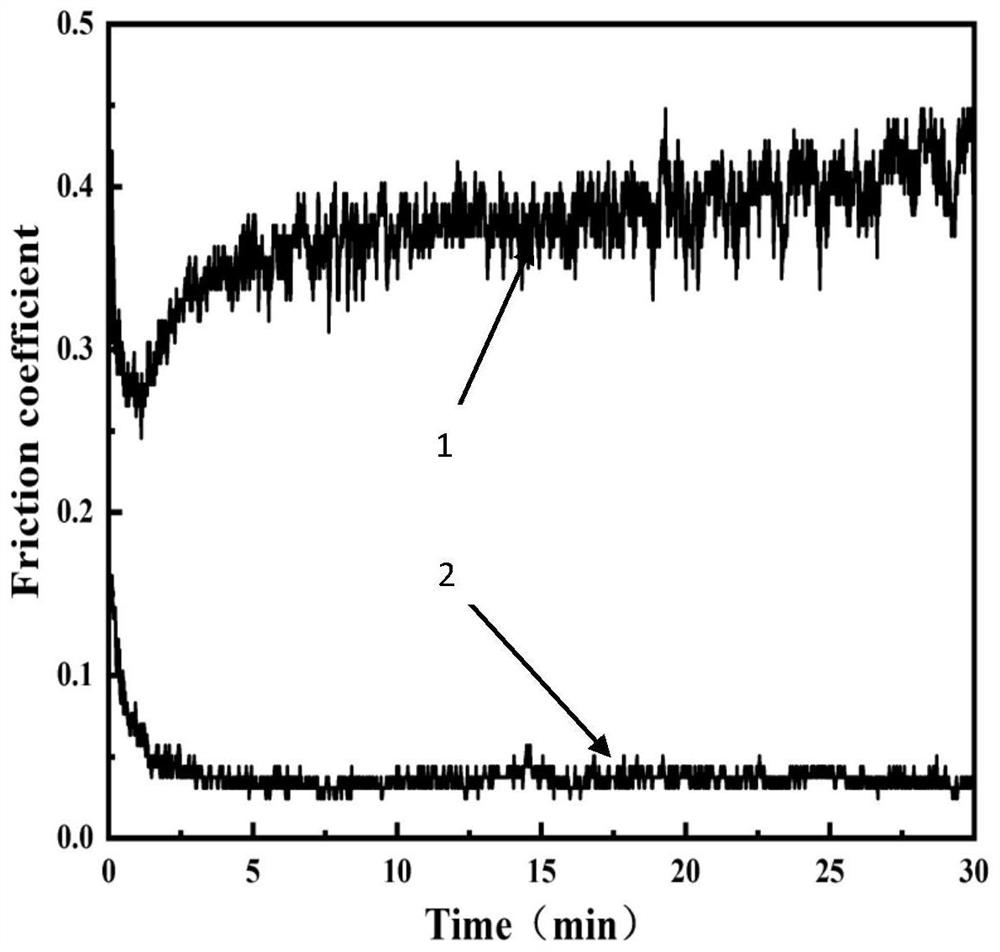

A low friction coefficient, composite coating technology, applied in the coating, metal material coating process, superimposed layer plating, etc., can solve the problem of poor bonding strength, low material fatigue strength, poor wear resistance and corrosion resistance, etc. Problems, to achieve high interface bonding strength, high hardness wear resistance, excellent wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a CrAlN / CrAlSiN / TaC composite coating with low friction coefficient and high wear resistance and a preparation method thereof, comprising the following steps:

[0031] Step 1. Cut the TC4 titanium alloy sheet into 10mm×10mm×4mm samples, then use sandpaper and polishing machine to polish and clean;

[0032] Step 2. Plasma nitriding is performed on the sample in Step 1;

[0033] Step 3, vertically suspend the sample in Step 2 on the turret in the multi-arc ion plating chamber to deposit the composite coating;

[0034] Step 4. After the deposition is completed, turn off the power supply, stop the flow of argon and nitrogen, and take out the sample after cooling to room temperature with the furnace.

[0035] Further, the samples in step 1 are respectively placed in absolute ethanol, acetone and deionized water for ultrasonic cleaning for 10-15 minutes, and then taken out and dried;

[0036] Further, the temperature of the plasma nitriding in step 2 ...

Embodiment 2

[0044] The invention provides a CrAlN / CrAlSiN / TaC composite coating with low friction coefficient and high wear resistance and a preparation method thereof, comprising the following steps:

[0045] Step 1. Cut the TC4 titanium alloy sheet into 10mm×10mm×4mm samples, then use sandpaper and polishing machine to polish and clean;

[0046] Step 2. Plasma nitriding is performed on the sample in Step 1;

[0047] Step 3, vertically suspend the sample in Step 2 on the turret in the multi-arc ion plating chamber to deposit the composite coating;

[0048] Step 4. After the deposition is completed, turn off the power supply, stop the flow of argon and nitrogen, and take out the sample after cooling to room temperature with the furnace.

[0049] Further, the samples in step 1 are respectively placed in absolute ethanol, acetone and deionized water for ultrasonic cleaning for 10-15 minutes, and then taken out and dried;

[0050] Further, the temperature of the plasma nitriding in step 2 is...

Embodiment 3

[0058] The invention provides a CrAlN / CrAlSiN / TaC composite coating with low friction coefficient and high wear resistance and a preparation method thereof, comprising the following steps:

[0059] Step 1. Cut the TC4 titanium alloy sheet into 10mm×10mm×4mm samples, then use sandpaper and polishing machine to polish and clean;

[0060] Step 2. Plasma nitriding is performed on the sample in Step 1;

[0061] Step 3, vertically suspend the sample in Step 2 on the turret in the multi-arc ion plating chamber to deposit the composite coating;

[0062] Step 4. After the deposition is completed, turn off the power supply, stop the flow of argon and nitrogen, and take out the sample after cooling to room temperature with the furnace.

[0063] Further, the samples in step 1 are respectively placed in absolute ethanol, acetone and deionized water for ultrasonic cleaning for 10-15 minutes, and then taken out and dried;

[0064] Further, the temperature of the plasma nitriding in step 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com