Lithium metal negative electrode composite modification method

A lithium metal negative electrode, modification and modification technology, applied in battery electrodes, lithium storage batteries, secondary battery repair/maintenance, etc., can solve problems such as unfavorable low-carbon production, increase production energy consumption, etc. Effects of non-uniform growth, low condition requirements, excellent ionic conductivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

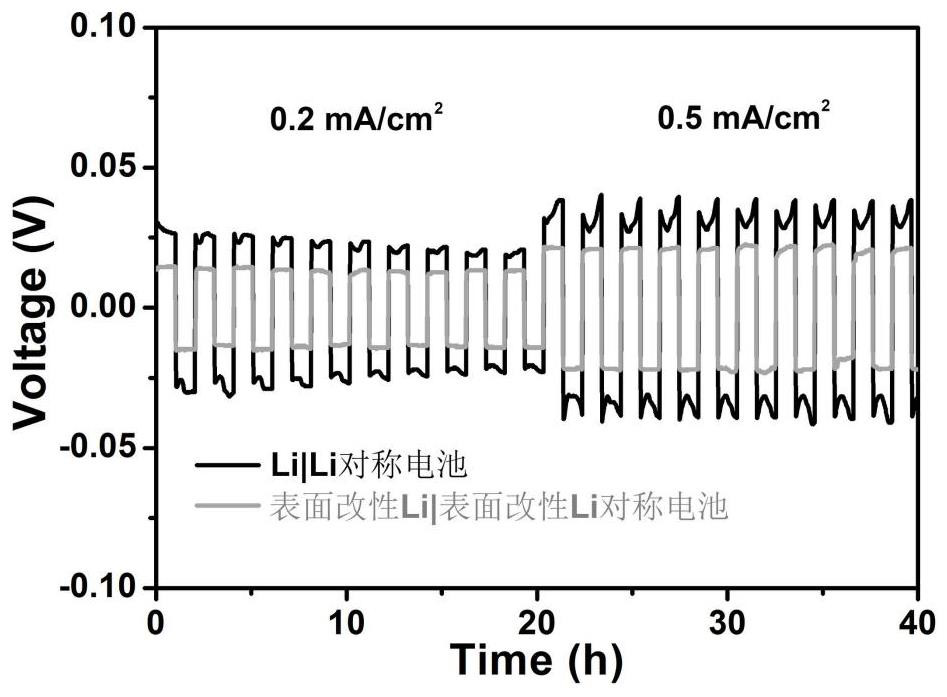

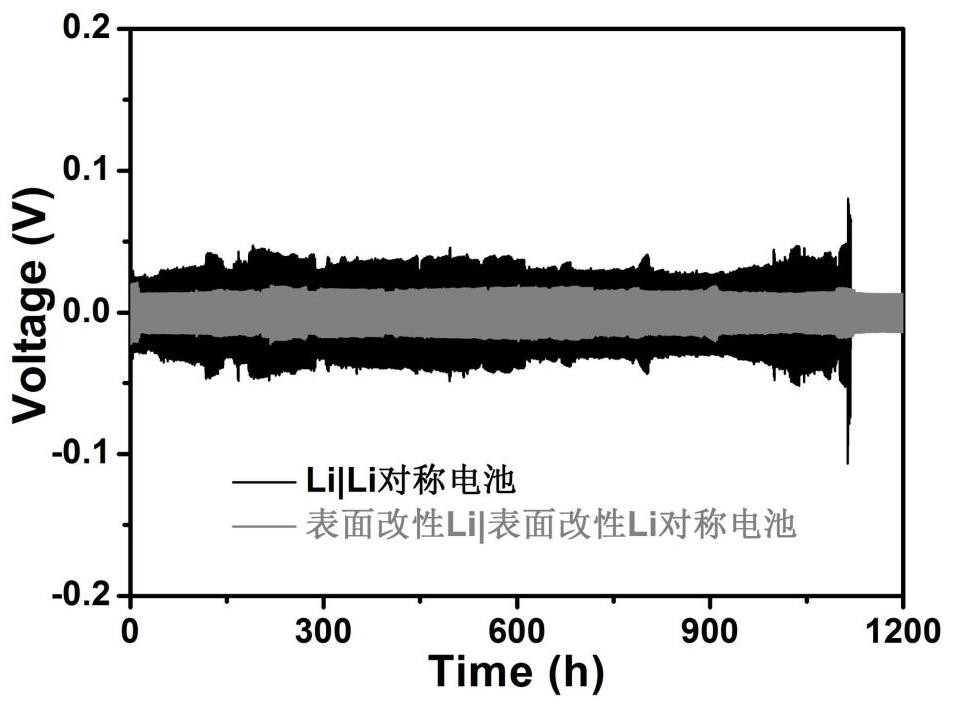

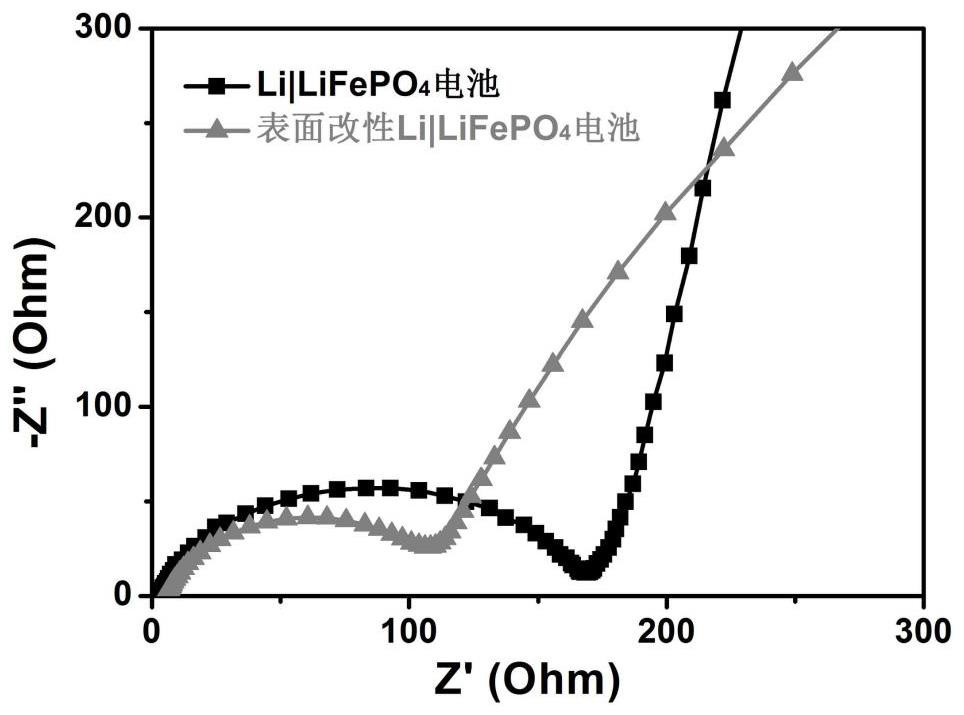

Examples

Embodiment 1

[0044] A method for compound modification and modification of a lithium metal negative electrode, comprising the following steps:

[0045] (1) Preparation of α-lipoic acid solution:

[0046] In an argon-protected glove box, dissolve α-lipoic acid in propylene carbonate, and stir at room temperature to prepare α-lipoic acid solution;

[0047] (2) Dissolving antimony trifluoride:

[0048] In an argon-protected glove box, dissolve antimony trifluoride in α-lipoic acid solution, stir at room temperature to prepare a mixed solution; the concentration of α-lipoic acid in the mixed solution is 0.05mol / L, SbF 3 The concentration of 0.1mol / L;

[0049] (3) Lithium metal sheet pretreatment:

[0050] Place the lithium metal sheet in a glove box protected by argon gas, and use a brush to brush the lithium metal sheet in tetrahydrofuran until the surface is glossy to obtain a polished lithium metal sheet, which is to be dried at 25°C after polishing;

[0051] (4) Modification of lithium m...

Embodiment 2

[0060] A method for compound modification and modification of a lithium metal negative electrode, comprising the following steps:

[0061] (1) Preparation of α-lipoic acid solution:

[0062] In an argon-protected glove box, dissolve α-lipoic acid in propylene carbonate, and stir at room temperature to prepare α-lipoic acid solution;

[0063] (2) Dissolving antimony trifluoride:

[0064] In an argon-protected glove box, dissolve antimony trifluoride in α-lipoic acid solution and stir at room temperature to prepare a mixed solution; the concentration of α-lipoic acid in the mixed solution is 0.01 mol / L, SbF 3 The concentration of 0.02mol / L;

[0065] (3) Lithium metal sheet pretreatment:

[0066] Place the lithium metal sheet in a glove box protected by argon gas, and use a brush to brush the lithium metal sheet in tetrahydrofuran until the surface is glossy to obtain a polished lithium metal sheet, which is to be dried at 25°C after polishing;

[0067] (4) Modification of li...

Embodiment 3

[0073] A method for compound modification and modification of a lithium metal negative electrode, comprising the following steps:

[0074] (1) Preparation of α-lipoic acid solution:

[0075] In an argon-protected glove box, dissolve α-lipoic acid in a mixed solvent with an equal molar ratio of propylene carbonate and dimethyl ether, and stir at room temperature to prepare α-lipoic acid solution;

[0076] (2) Dissolving antimony trifluoride:

[0077] In an argon-protected glove box, dissolve antimony trifluoride in α-lipoic acid solution, stir at room temperature to prepare a mixed solution; the concentration of α-lipoic acid in the mixed solution is 0.02mol / L, SbF 3 The concentration of 0.2mol / L;

[0078] (3) Lithium metal sheet pretreatment:

[0079] Place the lithium metal sheet in a glove box protected by argon gas, and use a brush to brush the lithium metal sheet in tetrahydrofuran until the surface is glossy to obtain a polished lithium metal sheet, which is to be drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com