Method for preparing trimethylamine gas sensor from NiO-In2O3 material with flower-shaped structure

A gas sensor, nio-in2o3 technology, applied in chemical instruments and methods, material resistance, gallium/indium/thallium compounds, etc., can solve the problems of difficult large-scale application, expensive, complex equipment, etc., and achieve low cost and good penetration The effect of stability and stability of the synthetic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Flower-like structure NiO-In 2 O 3 The composite material preparation method includes the following steps:

[0044] Step 1: Weigh a certain amount of indium chloride tetrahydrate InC l3 ⋅4H 2 O and Ni(NO) hexahydrate 3 ) 2 ⋅6H 2 O was dissolved in a mixed solution of 30 mL of distilled water and 10 mL of absolute ethanol. After stirring with a magnetic stirrer for 30 minutes at 40 °C, an appropriate amount of sodium lauryl sulfate and urea were added to the above solution, and stirring was continued for 30 minutes. Dissolve it completely to prepare a reaction solution of hydrothermal synthesis precursor;

[0045] Step 2: Pour the precursor reaction solution obtained in Step 1 into the polytetrachloroethylene lining of a 50 mL stainless steel reactor with a filling degree of 80%; keep it in a drying box at a temperature of 160 ° C for 5 hours, and then follow the furnace Cool to room temperature to obtain the reaction product;

[0046] Step 3: centrifuging the so...

Embodiment 1

[0055] (1) Preparation of flower-like structure In 2 O 3 Material

[0056] Step 1: Weigh 0.1466 g indium chloride tetrahydrate InCl 3 ⋅4H 2 O was dissolved in a mixed solution prepared by 30 mL of distilled water and 10 mL of absolute ethanol. After continuous stirring with a magnetic stirrer for 30 minutes at 40 °C, 0.2595 g of sodium dodecyl sulfate and 1.021 g of urea were added to the above solution, and continued. Stir for 30 minutes to make it completely dissolved, and prepare a reaction solution of hydrothermal synthesis precursor;

[0057] Step 2: Pour the precursor reaction solution obtained in Step 1 into the polytetrachloroethylene lining of a 50 mL stainless steel reactor, and the filling degree is 80% sealed;

[0058] Step 3: place the reaction kettle of Step 2 in a drying box and keep it at a temperature of 160°C for 5 hours, then cool down to room temperature with the furnace to obtain a reaction product;

[0059] Step 4: centrifuging the solution after the...

Embodiment 2

[0066] (1) Preparation of flower-like structure NiO-In 2 O 3 composite material

[0067] Step 1: Weigh 0.1466 g indium chloride tetrahydrate InCl 3 ⋅4H 2 O and 0.0044 g nickel nitrate hexahydrate (NO 3 ) 2 ⋅6H 2 O was dissolved in a mixed solution prepared by 30 mL of distilled water and 10 mL of absolute ethanol. After continuous stirring with a magnetic stirrer for 30 minutes at 40 °C, 0.2595 g of sodium dodecyl sulfate and 1.021 g of urea were added to the above solution, and continued. Stir for 30 minutes to make it completely dissolved, and prepare a reaction solution of hydrothermal synthesis precursor;

[0068] Steps two, three, four, five, and six are the same as in Example 1.

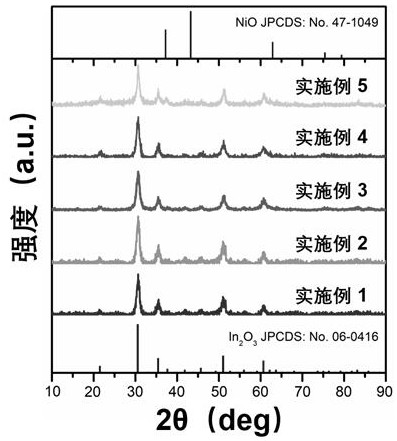

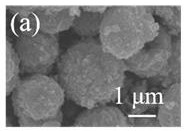

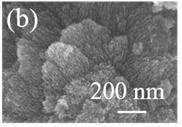

[0069] (2) Flower-like structure NiO-In 2 O 3 Structural Characterization of Composite Materials

[0070] The crystal structure of the product was characterized by XRD powder diffractometer (XRD, PANalytical X'Pert Pro). figure 1 X-ray diffraction (XRD) pattern of the sample. It can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com