One-dimensional high-entropy oxide nano material as well as preparation method and application thereof

A nanomaterial and oxide technology, applied in chemical instruments and methods, nickel compounds, nanotechnology, etc., can solve the problems of reducing the energy storage capacity and working life of high-entropy oxide anode materials, poor structural stability, and small specific surface area. , to achieve the effects of excellent structural stability, high electrical conductivity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

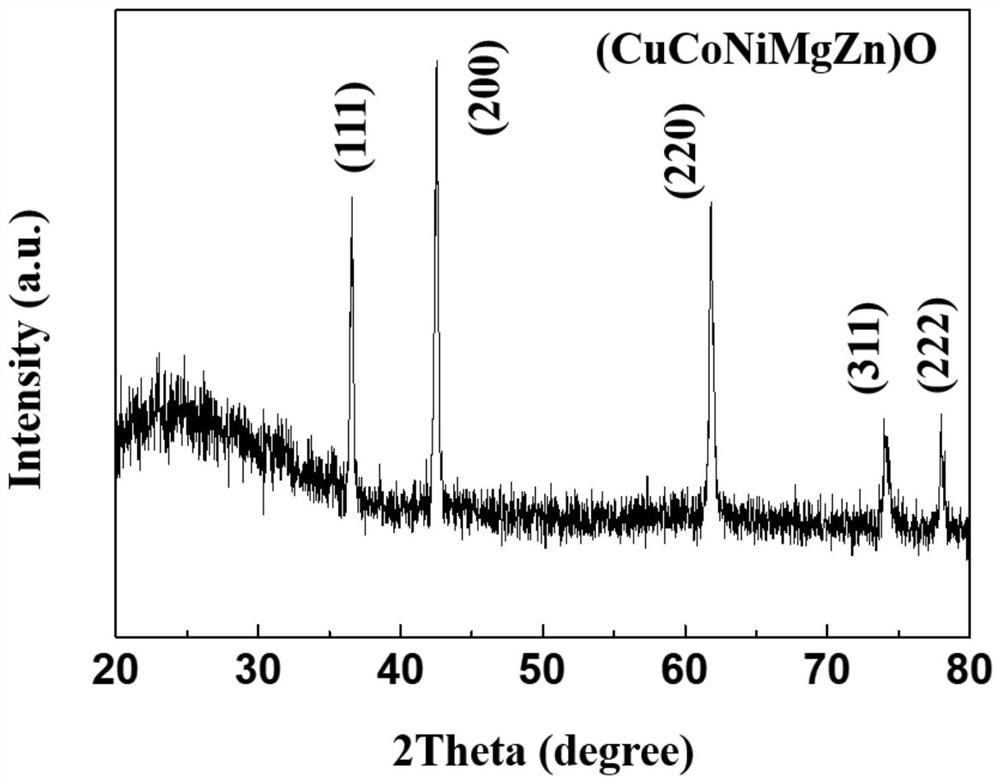

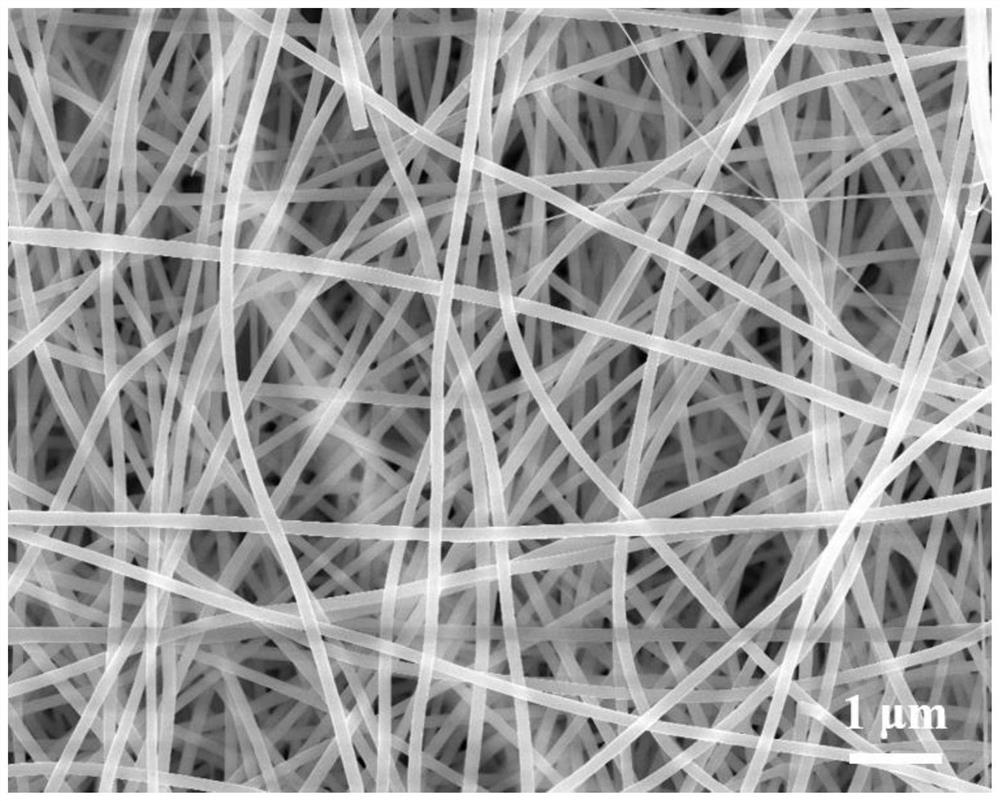

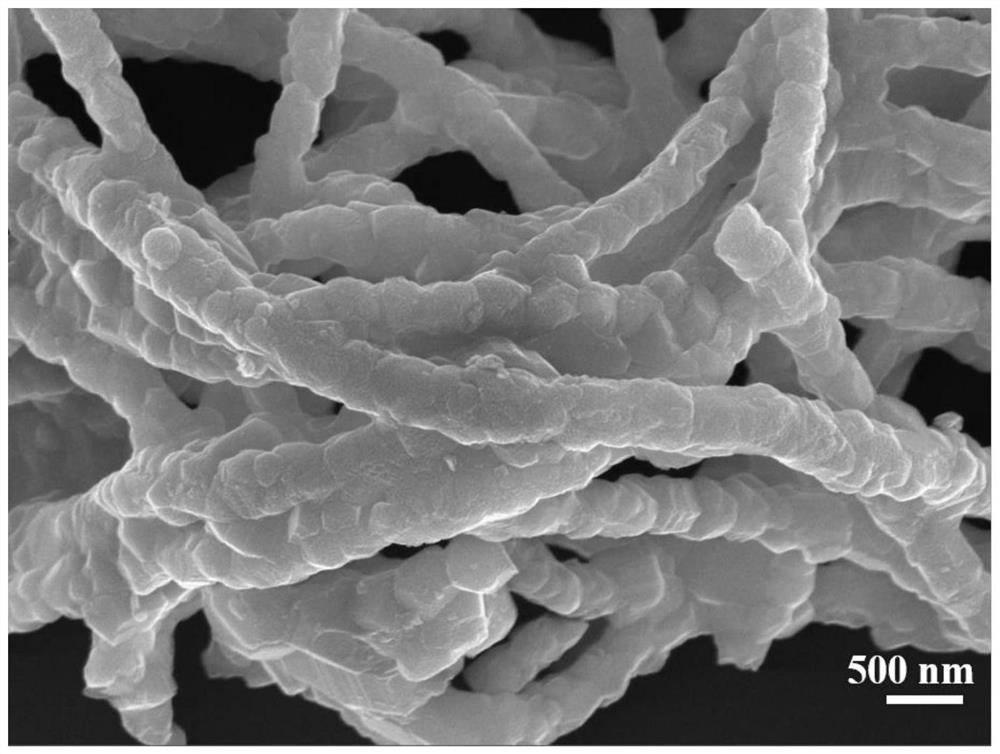

[0035] The preparation method of one-dimensional rock-salt type high-entropy oxide (CuCoNiMgZn)O nanomaterial comprises the following steps:

[0036] (1), get 2g of polyvinylpyrrolidone (Shanghai McLean Biochemical Technology Co., Ltd., molecular weight: 1,300,000) and pour it into 10 mL of N,N dimethylformamide solvent, and continue stirring for 12h to fully dissolve it to form a transparent solution;

[0037] (2), add 2mmol copper acetate, 2mmol cobalt acetate, 2mmol nickel acetate, 2mmol magnesium acetate and 2mmol zinc acetate successively in the solution prepared in step (1), continue to stir to dissolve completely, obtain dark blue slurry with this, The slurry is a metal precursor solution;

[0038] (3), suck the metal precursor solution prepared in step (2) through a syringe with a specification of 10mL, the syringe is equipped with a 19G stainless steel needle, and the syringe is fixed on the syringe pump, and the aluminum foil receiving plate is placed vertically 15c...

Embodiment 2

[0048] One-dimensional spinel-type high-entropy oxide (FeCoNiCrMn) 3 O 4 The preparation of nanomaterials includes the following steps:

[0049] (1) Pour 2g of polyvinylpyrrolidone (Shanghai McLean Biochemical Technology Co., Ltd., molecular weight: 1,300,000) into 10mL of N,N dimethylformamide solvent, and continue stirring for 12h to fully dissolve to form a transparent solution.

[0050] (2), add 1mmol ferric chloride, 1mmol cobalt chloride, 1mmol nickel chloride, 1mmol chromium chloride and 1mmol manganese chloride to the solution prepared in step (1) successively, continue stirring until the formation of uniform electrospinning silk pulp;

[0051] (3), transfer the electrospinning slurry prepared in step (2) into a 10mL syringe equipped with a 21G stainless steel needle, fix the syringe on the syringe pump, and receive the aluminum foil The plate was placed 15cm in front of the stainless steel needle, and the negative clip was connected, and the front end of the needle...

Embodiment 3

[0061] An application of a one-dimensional high-entropy oxide nanomaterial as a negative electrode material for a lithium ion battery, specifically a preparation method for a negative electrode material for a lithium ion battery, comprising the following steps:

[0062] 1. Take 40 mg of the (CuCoNiMgZn)O powder obtained in step (4) of Example 1, mix it with 5 mg of acetylene black and 5 mg of PVDF powder, and grind it into a uniform powder, add dropwise an appropriate amount of N-methylpyrrolidone ( NMP) continue to grind until a uniform slurry is formed for later use, take a piece of 20cm×20cm copper foil, fix it in a glass plate, clean and wipe with ethanol to remove surface contaminants;

[0063] 2. Pour the slurry prepared in step 1 on the copper foil, apply it with a 100μm scraper, so that the slurry is evenly spread on the surface of the copper foil, and then put the copper foil into a vacuum oven, vacuum at a temperature of 80 ℃ Dry for 12h;

[0064] 3. Take out the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com