Method for extracting high-purity nervonic acid from acer truncatum oil

A technology of nervonic acid and Yuanbao maple, which is applied in chemical instruments and methods, carboxylate preparation, fatty acid production, etc., can solve the problems of restricting the large-scale production of high-purity nervine acid, achieve large-scale production, low process cost, The effect of low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

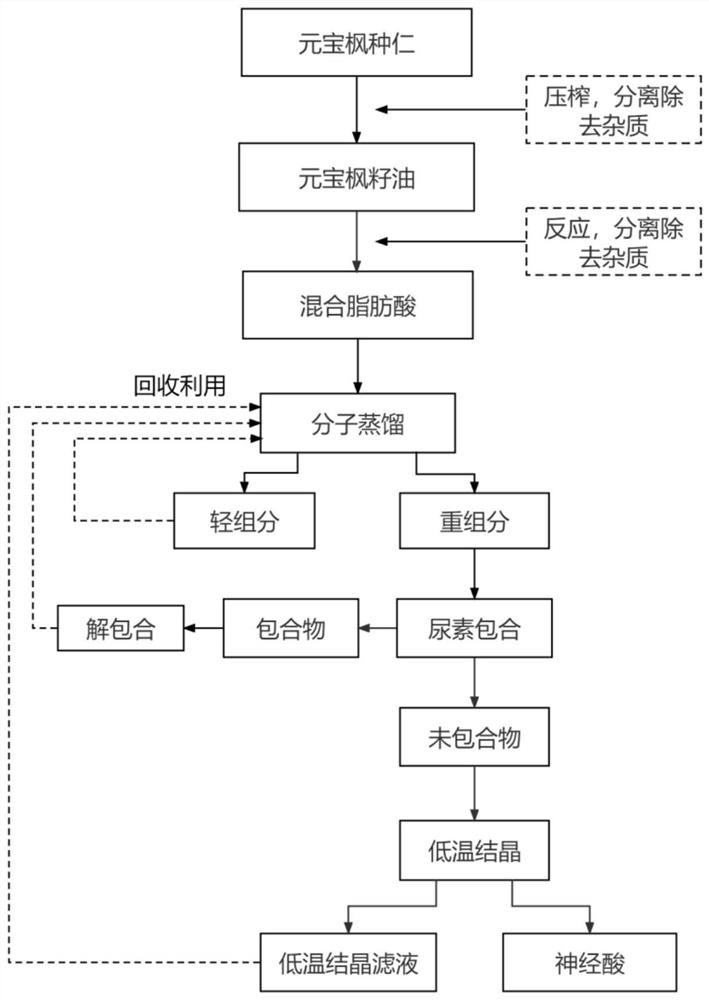

Image

Examples

Embodiment 1

[0057] (1) Yuanbao maple seed kernels are washed with water to remove residual shells, unshelled Yuanbao maple seeds and moldy grains; drying to adjust the water content of seeds to 3%, and pressing with a shaft screw press, the pressing temperature is 120 ℃, to obtain Yuanbao maple crude oil; centrifuge Yuanbao maple crude oil at 8000r / min to remove impurities to obtain Yuanbao maple seed oil;

[0058] (2) mixing absolute ethanol and Yuanbao maple seed oil in a mass ratio of 1:1, adding 10% potassium hydroxide catalyst by weight of Yuanbao maple seed oil, and reacting at 100 ° C for 4 hours;

[0059] (3) after the reaction finishes, adjust pH to 3 with 15% aqueous HCl solution, then extract twice with petroleum ether, and combine the petroleum ether layers obtained by extraction; At 70℃, under the condition of vacuum degree of 0.05Mpa, the petroleum ether was removed by evaporation, and the mixed fatty acid was obtained;

[0060] (4) the mixed fatty acids obtained in step (3...

Embodiment 2

[0064] (1) Yuanbao maple seed kernels are washed with water to remove residual shells, unshelled Yuanbao maple seeds and moldy grains; drying to adjust the water content of seeds to 2%, and pressing with a shaft screw press, the pressing temperature is 110 ℃, to obtain Yuanbao maple crude oil; centrifuge Yuanbao maple crude oil at 8000r / min to remove impurities to obtain Yuanbao maple seed oil;

[0065] (2) mixing absolute ethanol and Yuanbao maple seed oil in a mass ratio of 1:1, and adding a 7% potassium hydroxide catalyst by weight of Yuanbao maple seed oil, and reacting at 90 ° C for 5 hours;

[0066] (3) after the reaction finishes, adjust pH to 2 with 20% aqueous HCl solution, then extract twice with petroleum ether, and combine the petroleum ether layers obtained by extraction; At 80°C, under the condition of vacuum degree of 0.05Mpa, the petroleum ether was removed by evaporation, and the mixed fatty acid was obtained;

[0067] (4) the mixed fatty acids obtained in st...

Embodiment 3

[0071] (1) Yuanbao maple seed kernels are washed with water to remove residual shells, unshelled Yuanbao maple seeds and moldy grains; drying to adjust the water content of seeds to 3%, and pressing with a shaft screw press, the pressing temperature is 120 ℃, to obtain Yuanbao maple crude oil; centrifuge Yuanbao maple crude oil at 8000r / min to remove impurities to obtain Yuanbao maple seed oil;

[0072] (2) mixing absolute ethanol and Yuanbao maple seed oil in a mass ratio of 1:1, adding 7% potassium hydroxide catalyst by weight of Yuanbao maple seed oil, and reacting at 95 ° C for 5 hours;

[0073] (3) after the reaction finishes, adjust pH to 2 with 20% aqueous HCl solution, then extract twice with petroleum ether, and combine the petroleum ether layers obtained by extraction; At 80°C, under the condition of vacuum degree of 0.05Mpa, the petroleum ether was removed by evaporation, and the mixed fatty acid was obtained;

[0074] (4) the mixed fatty acids obtained in step (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com