Prepn process of oxygen place doped lithium ferric phosphate powder

A lithium iron phosphate, doping-type technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as ineffective effects, and achieve the effects of improving the basic capacity of the matrix, wide application prospects, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The specific method of preparing the oxygen-doped lithium iron phosphate powder is as follows:

[0029] 1) One-time mixing method of adulterants and parent raw materials

[0030] According to the lithium salt, ferrous salt and phosphate, mix the parent material according to the molar ratio of Li:Fe:P=1:1:1, and then mix the parent material once by the molar ratio of the parent body:dopant=1:0.001~2 material, and then add at least one of deionized water, industrial alcohol and absolute ethanol as a mixed medium to mix, mix and mill for 6 to 12 hours, and dry at 40 to 70°C; after drying, the powder is dried in nitrogen, argon Gas, at least one of nitrogen and hydrogen mixed gas in an inert atmosphere or a reducing atmosphere, heated at 400-550 ° C, and kept for 2-10 hours for pre-calcination; the matrix pre-calcined material was ball-milled for 6-12 hours, at 40-70 ℃, and then in an inert atmosphere or a reducing atmosphere of at least one of nitrogen, argon, and nitrogen-...

Embodiment 1

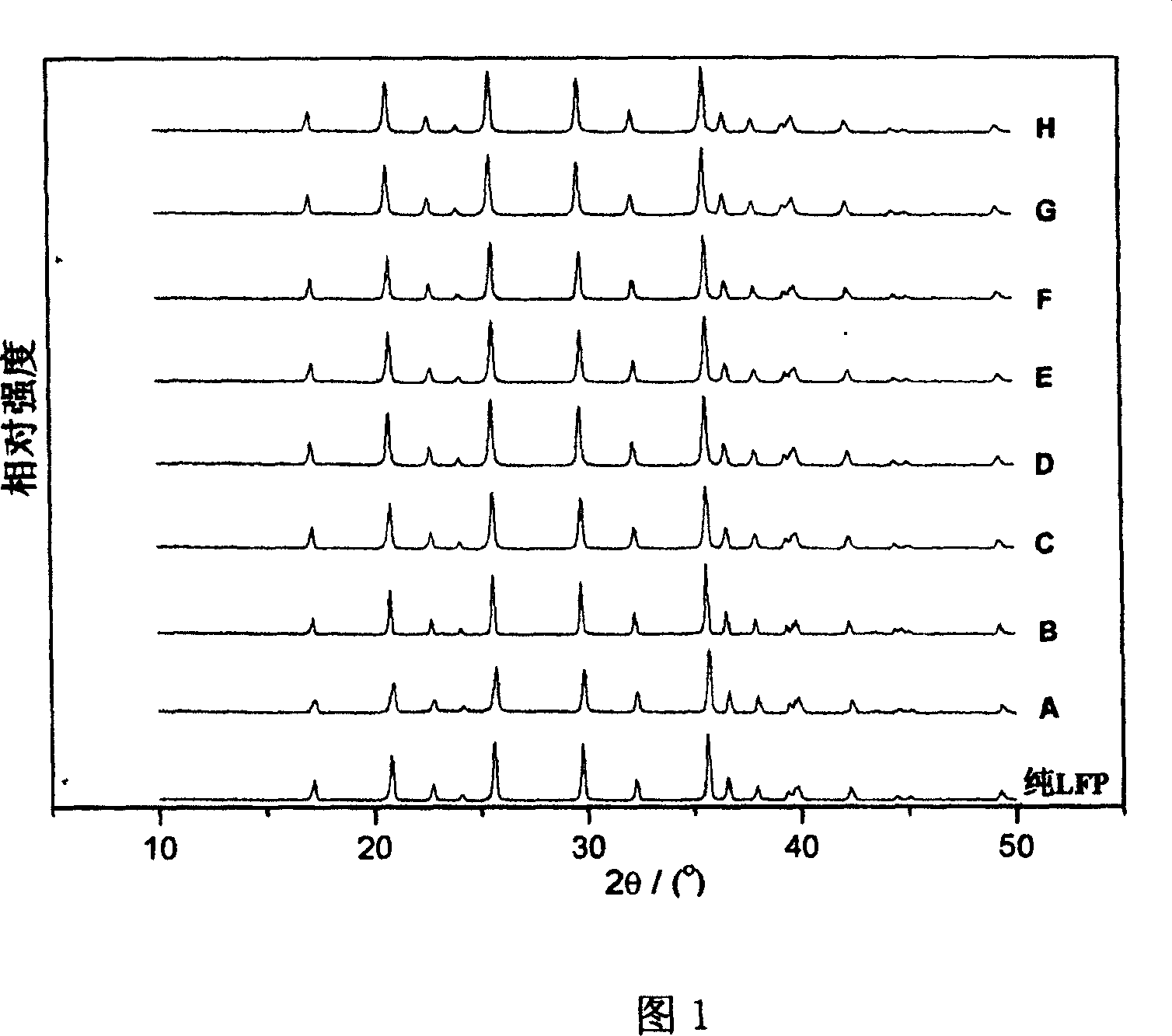

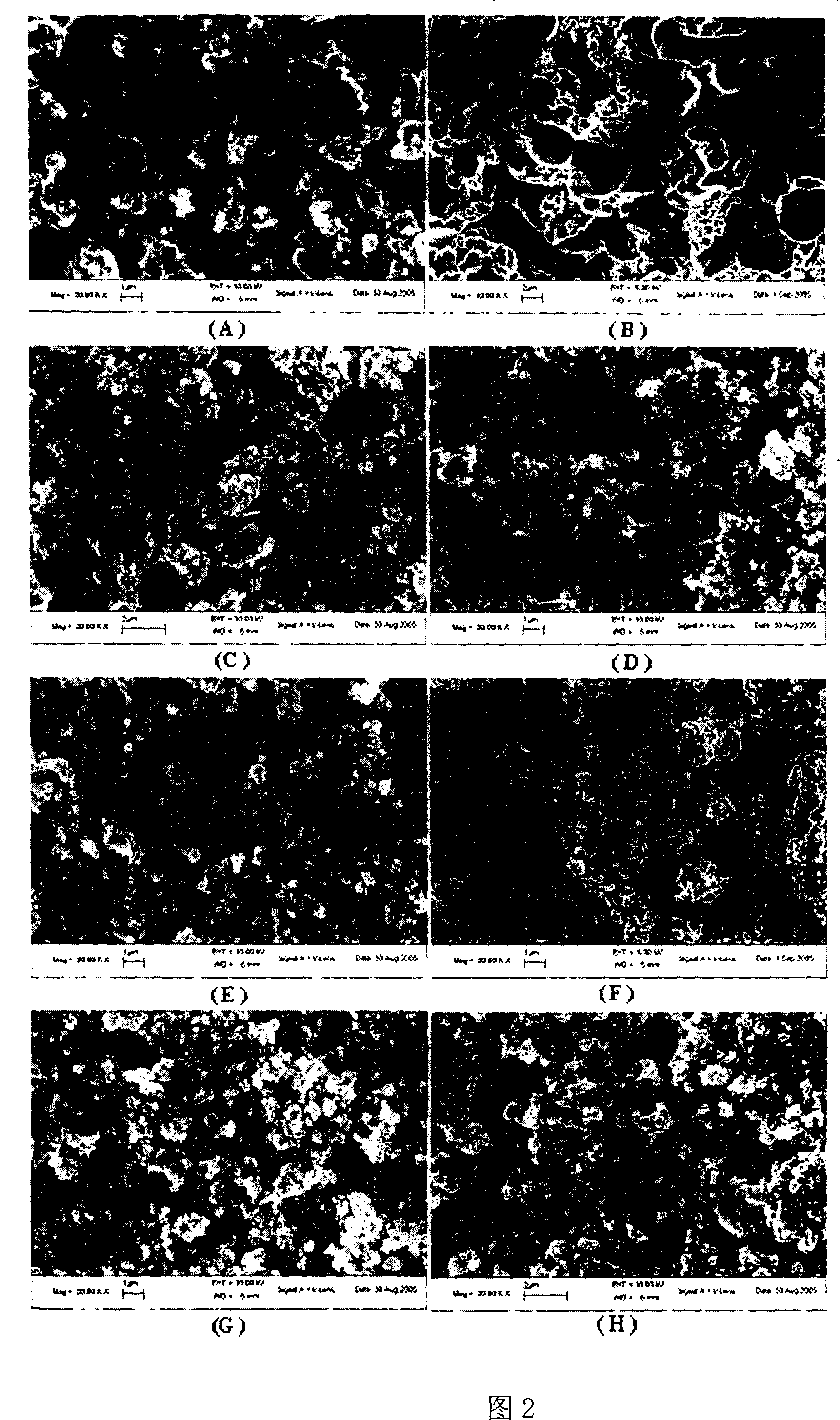

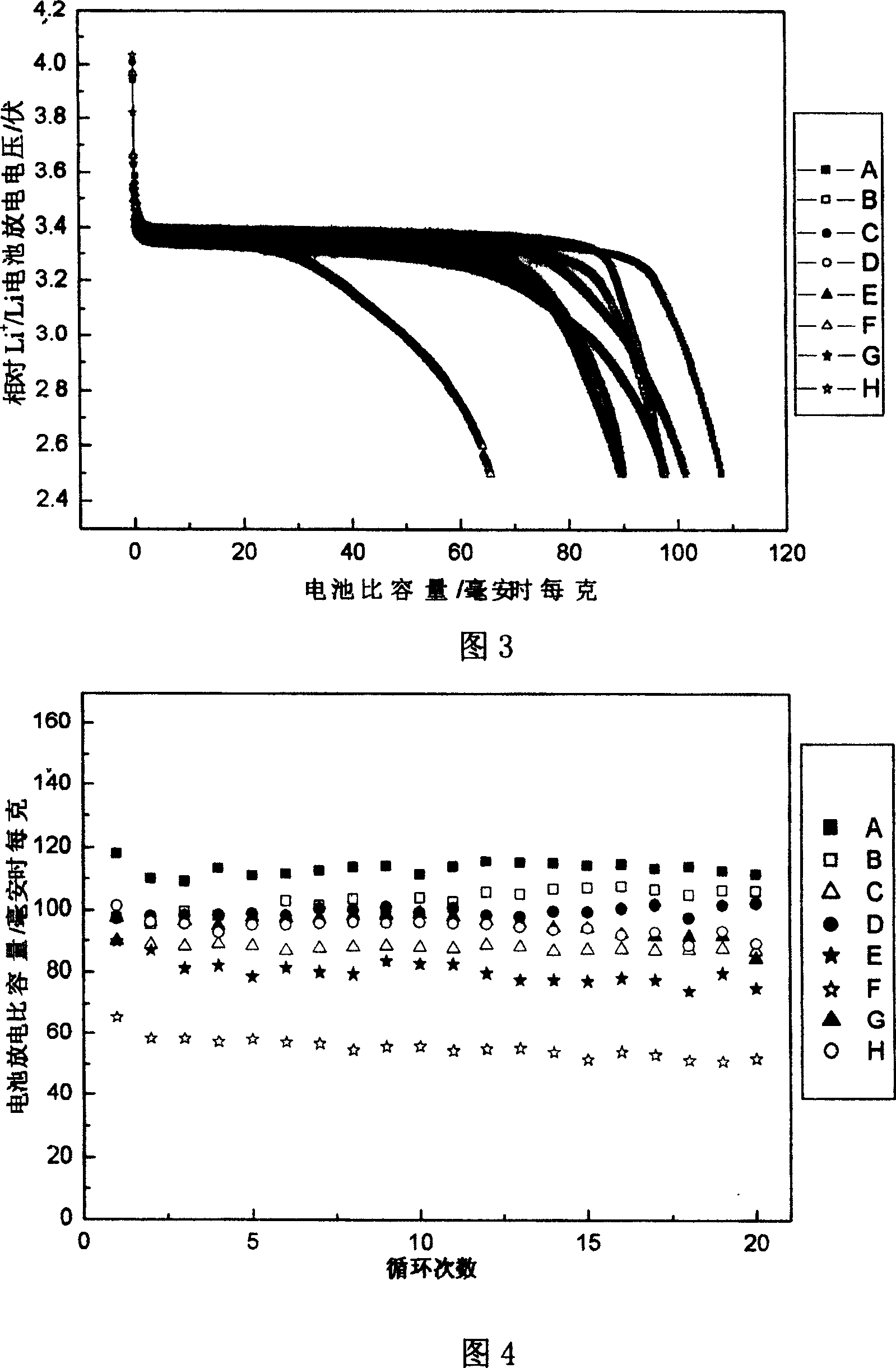

[0045] Mix 0.05 mol of lithium carbonate, 0.1 mol of ferrous oxalate and 0.1 mol of ammonium dihydrogen phosphate, add it to a polyester tank, add 25ml of absolute alcohol, seal it and mix it on a planetary ball mill for 10 hours, under 0.3 liters / minute of nitrogen Under the atmosphere, raise the temperature up to 400°C at a rate of 5°C / min, keep at this temperature for 8 hours, and cool down to room temperature with the furnace, take out 0.1 mole of precursor pre-fired material, add 0.04 mole of thiourea to the polyester tank, and add an appropriate amount of alcohol , ball milled for 6 hours after sealing, and then raised to 700°C at a rate of 4°C / min under a nitrogen atmosphere of 0.3 liters / min, kept at this temperature for 8 hours, and cooled to room temperature with the furnace. The resulting cathode material is LiFePS 0.4 o 3.6 , denoted as sample A. A in Figure 1 is the obtained LiFePO 4 The XRD pattern of the dopant did not change the LiFePO 4 The crystal structu...

Embodiment 2

[0048] Mix 0.05 lithium carbonate with 0.1 mole of ferrous oxalate, 0.1 mole of ammonium dihydrogen phosphate and 0.062 mole of elemental sublimed sulfur, add it to a polyester tank, add 30ml of absolute alcohol, seal it and mix it on a planetary ball mill for 6 hours. Under the nitrogen atmosphere of l / min, raise the temperature to 430°C at a rate of 5°C / min, keep at this temperature for 7.5 hours, cool down to room temperature with the furnace, take out 0.1 mole of the precursor pre-fired material and add it to the polyester tank, add an appropriate amount Alcohol, sealed and ball milled for 10 hours, then in a nitrogen-hydrogen mixed atmosphere of 0.3 liters / min (nitrogen: hydrogen = 9:1, volume ratio), the temperature rises to 720°C at a rate of 4°C / min, and is kept at this temperature After 7 hours, cool down to room temperature with the furnace. The resulting cathode material is LiFePS 0.6 2O 3.38 , denoted as sample B. B in Figure 1 is the obtained LiFePO 4 The XRD ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com