Process for preparing tetragonal nanoparticles of barium titanate

A technology of phase barium titanate and nano powder, which is applied in the field of preparing tetragonal phase barium titanate nano powder, can solve the problems of low purity, growth, expensive raw materials, etc., and achieve simple preparation process, process parameter control, process parameter easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

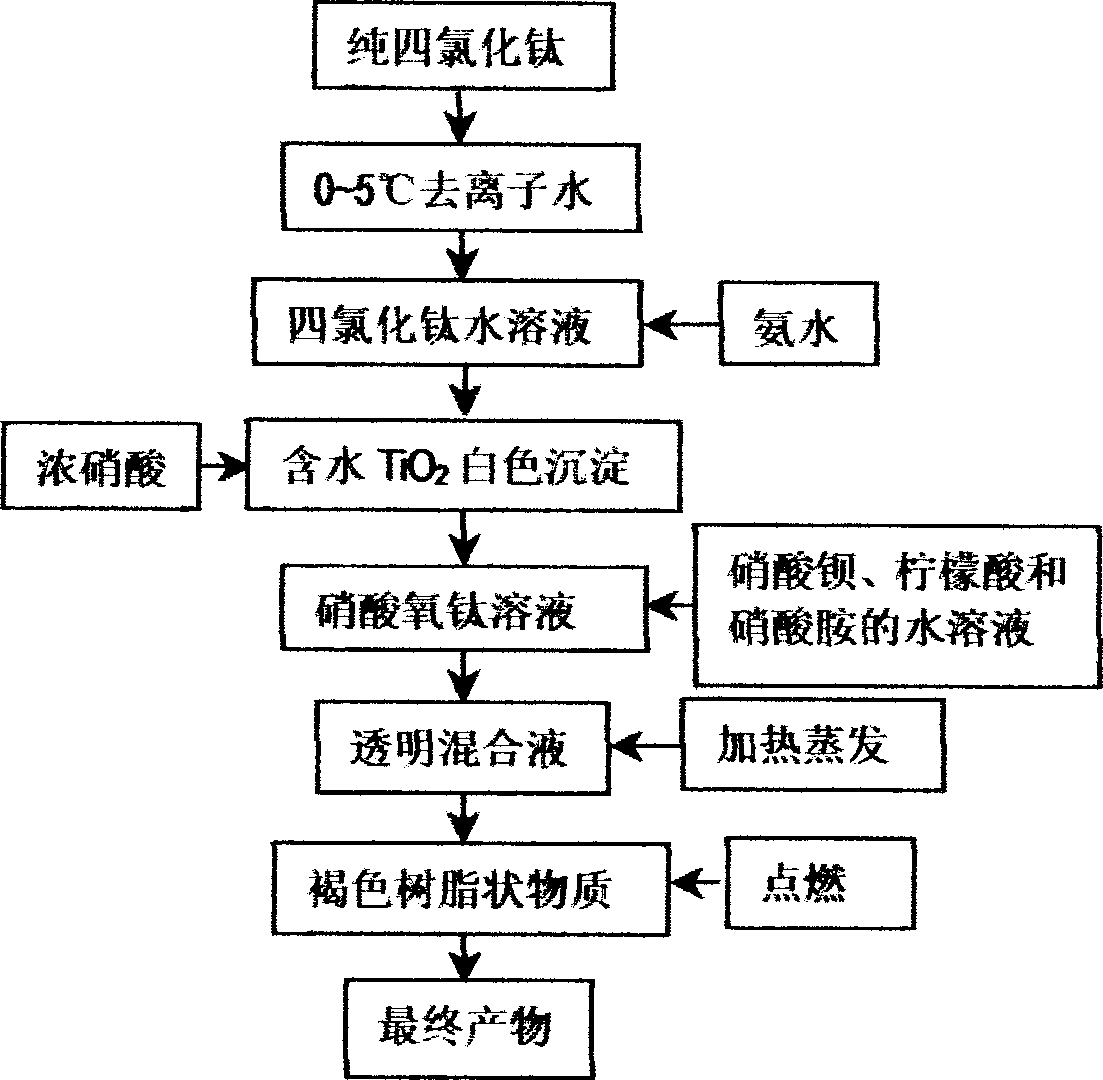

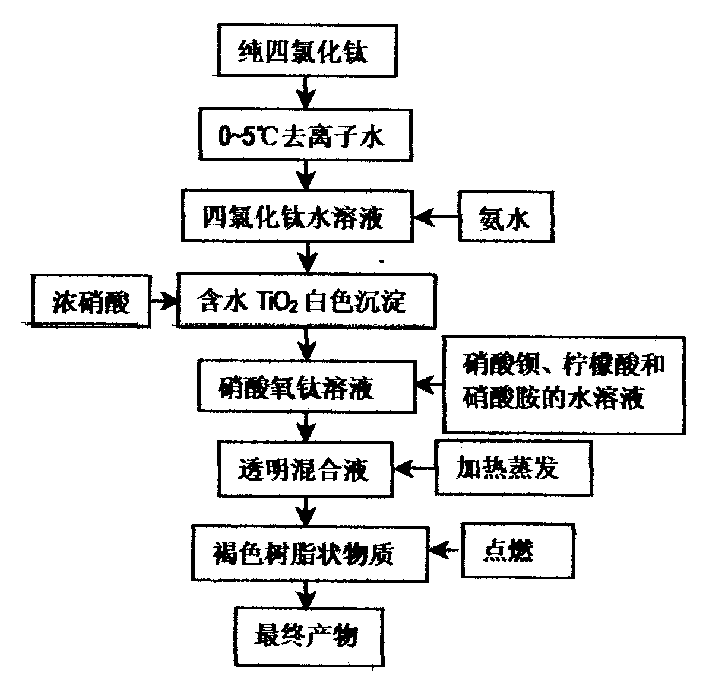

[0022] Example 1: Add 10ml of titanium tetrachloride dropwise to 50ml of ice water to form an aqueous solution of titanium tetrachloride, then add 1 liter of 1.5 mol / liter of ammonia water to form white hydrated TiO 2 The precipitate was dissolved in 12.2ml of concentrated nitric acid in an ice bath environment. If it cannot be dissolved temporarily, it can be placed in the freezer at low temperature to achieve dissolution. This gives a transparent titanyl nitrate solution. Barium nitrate, titanyl nitrate, citric acid and ammonium nitrate are mixed in a molar ratio of 1:1:3:17, and the mixed aqueous solution is adjusted to a pH value of 6-7 with ammonia water, and then heated and evaporated at 95°C until the water is evaporated to dryness. It is a brown viscous substance accompanied by bubbles. The ignition temperature is about 300°C when it is ignited and burns rapidly. The reaction is completed within a few minutes and a fluffy white titanium-barium powder is formed. It is ...

Embodiment 2

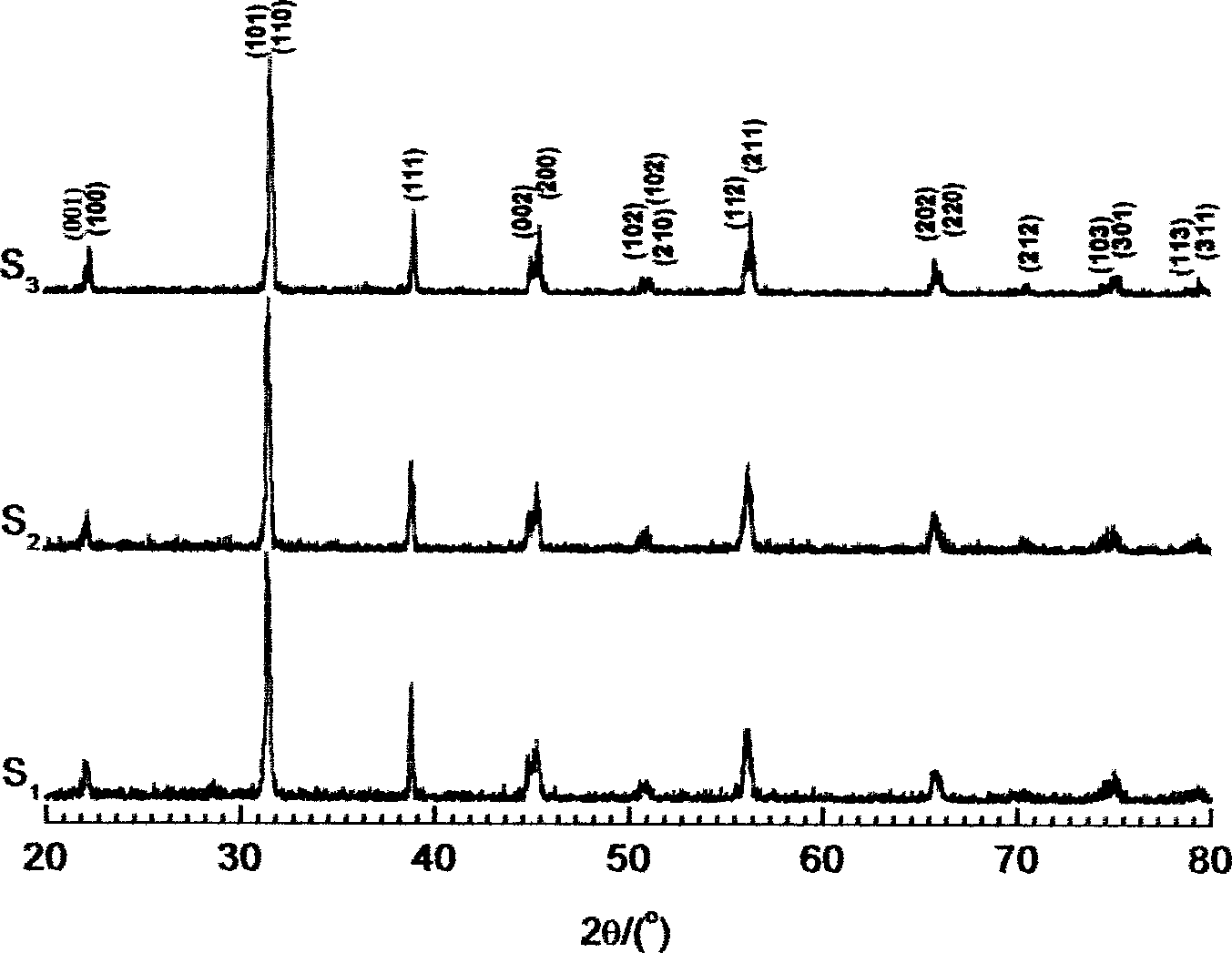

[0023] Embodiment 2: barium nitrate, titanyl nitrate, citric acid and ammonium nitrate are mixed with 1: 1: 2: 8 molar ratio, other is the same as embodiment 1. Such as figure 2 X-ray diffraction pattern (S 1 ), the X-ray diffraction analysis results show that the powder is tetragonal phase barium titanate, and does not contain the diffraction peaks of cubic phase barium titanate and barium carbonate. The grain size is about 50-80nm.

Embodiment 3

[0024] Embodiment 3: barium nitrate, titanyl nitrate, citric acid and ammonium nitrate are mixed with 1: 1: 4: 26 molar ratio, other is the same as embodiment 1. Such as figure 2 X-ray diffraction pattern (S 3 ), the X-ray diffraction analysis results show that the powder is tetragonal phase barium titanate, and does not contain the diffraction peaks of cubic phase barium titanate and barium carbonate. The grain size is about 100-150nm.

[0025] figure 2 For the X-ray diffraction pattern of the barium titanate nanocrystal prepared by the method provided by the invention, the diffraction pairs such as (001), (100), (200), (102), (112), (211) appearing in the figure The peak is the characteristic diffraction peak of tetragonal barium titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com