Method and device for directly synthesizing hydrogen peroxide at room temperature for epoxidation of propylene

A technology of hydrogen peroxide and epoxidation, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the difficulty of catalyst preparation , low hydrogen peroxide efficiency, difficult condition control and other problems, to solve the problem of heat removal, improve discharge uniformity, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (comparative example)

[0032] Hydrogen and oxygen are regulated by a flow meter and a regulating valve, and then mixed in the pipeline at a flow rate of 100 ml / min and 2 ml / min respectively, and then enter a common wire barrel type dielectric barrier discharge plasma generator. The shell of the generating device is made of silicate oxide hard glass, the wall thickness is 1.5 mm, the inner diameter is 9 mm, and the length of the discharge area is 220 mm. The generating device uses a metal copper wire with a smooth surface as the discharge electrode, and its diameter is 0.56 mm. The ground electrode of the generating device is a metal copper mesh tightly surrounding the glass shell. The generating device works in the atmospheric environment. The gas mixture after passing through the plasma of the generator was sparged in a trap containing 10 ml of methanol and then evacuated. After ventilating for 5 minutes, turn on the high-voltage AC power supply, adjus...

Embodiment 2

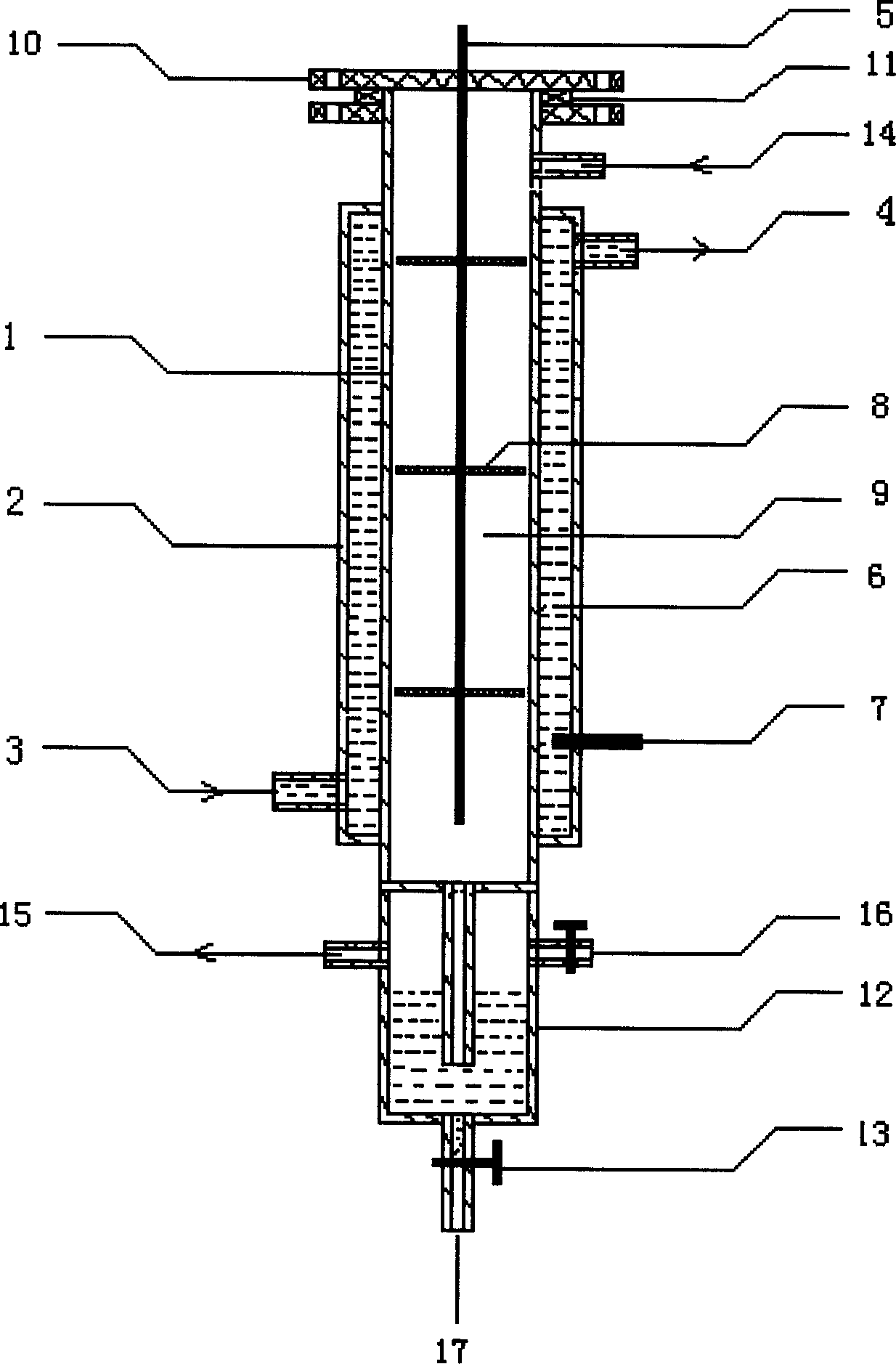

[0038] Example 1 was repeated, but using the self-cooling dielectric barrier discharge plasma generator of the present invention. The shell sleeve of the generating device is made of silicate oxide hard glass, the wall thickness of the inner cylinder is 1.5 mm, the inner diameter is 9 mm, and the length of the discharge area is 220 mm. The thickness of the annular gap between the inner and outer cylinders is 10 mm, and the length of the annular gap is the same as that of the discharge area. The generating device uses a metal copper wire with a smooth surface as the discharge electrode, and its diameter is 0.56 mm. The grounding electrode of the generator is served by tap water filled with annulus (conductivity is 0.078 mS / cm), the water temperature is constant at 16°C, the circulation flow rate is 1.4 liters / min, and the temperature difference between the inlet and outlet of the circulating water is controlled within 1°C. The current lead-out wire of the generating device is ...

Embodiment 3

[0044] Repeat Example 2, but the casing sleeve of the generating device is made of silicate oxide quartz glass, the discharge electrode is 18Ni9Ti stainless steel alloy, and the grounding electrode of the generating device is made of an annular gap containing 2% (mass) of sodium chloride The aqueous solution (conductivity is 9.2 3 mS / cm), then the discharge voltage of the generating device is 10KV, and the results obtained under different discharge times are:

[0045] Discharge for 10 minutes, the temperature of the inner wall of the generating device is 17oC, and the concentration of hydrogen peroxide in the collected liquid is 7.0 mmol / L;

[0046] Discharge for 30 minutes, the temperature of the inner wall of the generating device is 17oC, and the concentration of hydrogen peroxide in the collected liquid is 24.2 mmol / L;

[0047] Discharge for 60 minutes, the temperature of the inner wall of the generating device is 17oC, and the concentration of hydrogen peroxide in the col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com