Polysaccharose film of brevibacterium and its use in bacteria preservisation

A pullulan polysaccharide and film technology, which is applied in the preservation of microorganisms and other directions, can solve the problems of long preservation period and high cost, and achieve the effects of low preservation cost, convenient use and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

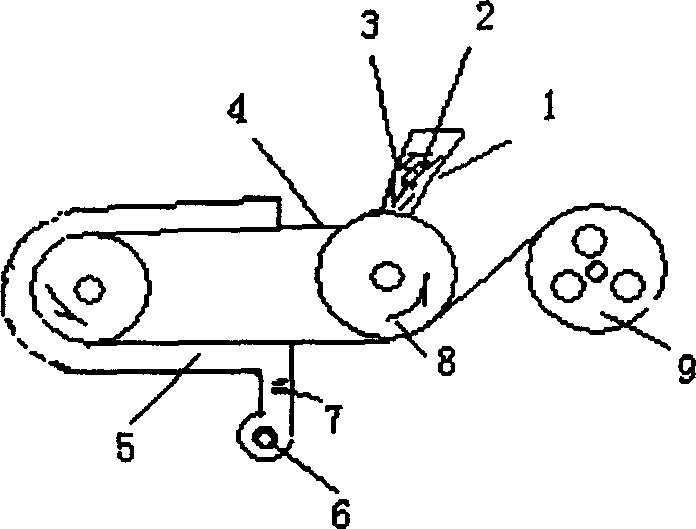

[0032] Rice starch is hydrolyzed to obtain a mixture of glucose and oligosaccharides, and the mixture is prepared into a culture medium, which is fermented by Aureobasidium into pullulan. The polysaccharide is separated by bacteria, decolorized, filtered, refined, concentrated to a concentration of 20g / 100ml, injected into the spray film head, the nozzle opening is 0.1mm, sprayed with a constant pressure of 0.09MPa, and the circulating stainless steel belt is evenly connected to the film. Dry with hot air at 80°C to obtain a roll of 0.03mm thick transparent and dry polysaccharide film. The measured performance indicators are as follows:

[0033] Tensile strength 32Mpa right angle tear strength 38KN / m

[0034] Light transmittance 96% Oxygen transmission rate 1.6cm 3 / m 2 .bar.d

Embodiment 2

[0036] Cut the polysaccharide film prepared in Example 1 into 10mm×10mm unit pieces, place them in a sterile room, and irradiate the film with a 15W ultraviolet lamp at a distance of 20cm for 5 minutes, 10 minutes, 15 minutes, 20 minutes, and 30 minutes respectively. Sterilization, after sterilization, dissolve the diaphragm with a small amount of physiological saline, and then spread it on the plates of complete medium and broth medium respectively and culture it at 30°C for 6 days. The observation results are as follows:

[0037] Irradiation time (minutes) 5 10 15 20 30

[0038] Number of colonies on complete medium 17 3 0 0 0

[0039] Number of colonies on broth medium 13 1 0 0 0

[0040] The polysaccharide membrane can be completely sterilized by ultraviolet irradiation for 15 minutes. For safety reasons, the irradiation time can be extended to 20 minutes

Embodiment 3

[0042] Several polysaccharide membranes prepared in Example 1 were irradiated with ultraviolet rays for 20 minutes for use, and the commercially available nylon composite membranes were cut into a size of 15mm×15mm, and sterilized at 121°C for 30 minutes for use.

[0043] Take the slant strains of Escherichia coli (AS1.751), Corynebacterium Beijing (AS1.299), Bacillus subtilis (AS1.339) and Brevibacterium flavum (AB91058) respectively, smear them on the plate broth medium, and culture them at 32°C , grow into a single colony;

[0044]Smear the yeast (AY91014) on the malt juice agar medium of the plate, culture at 30°C to form a single colony; take out Aureobasidium pullulans AS3. In the sterile room, pick the above-mentioned 6 strains of single colonies from the petri dish (the size of each colony of each strain is basically equal), and spread them on the above-mentioned sterile polysaccharide film irradiated by ultraviolet rays, and then apply a thin layer on the other Glyce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com