Preparation method of biological composite material of hydroxyapatite and high polymer

A technology of hydroxyapatite and composite materials, applied in medical science, prosthesis, etc., can solve the problems of no microstructure, poor interface bonding strength, lack of chemical bonding, etc., and achieve improved biomechanical properties and biocompatibility. Improved, high bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

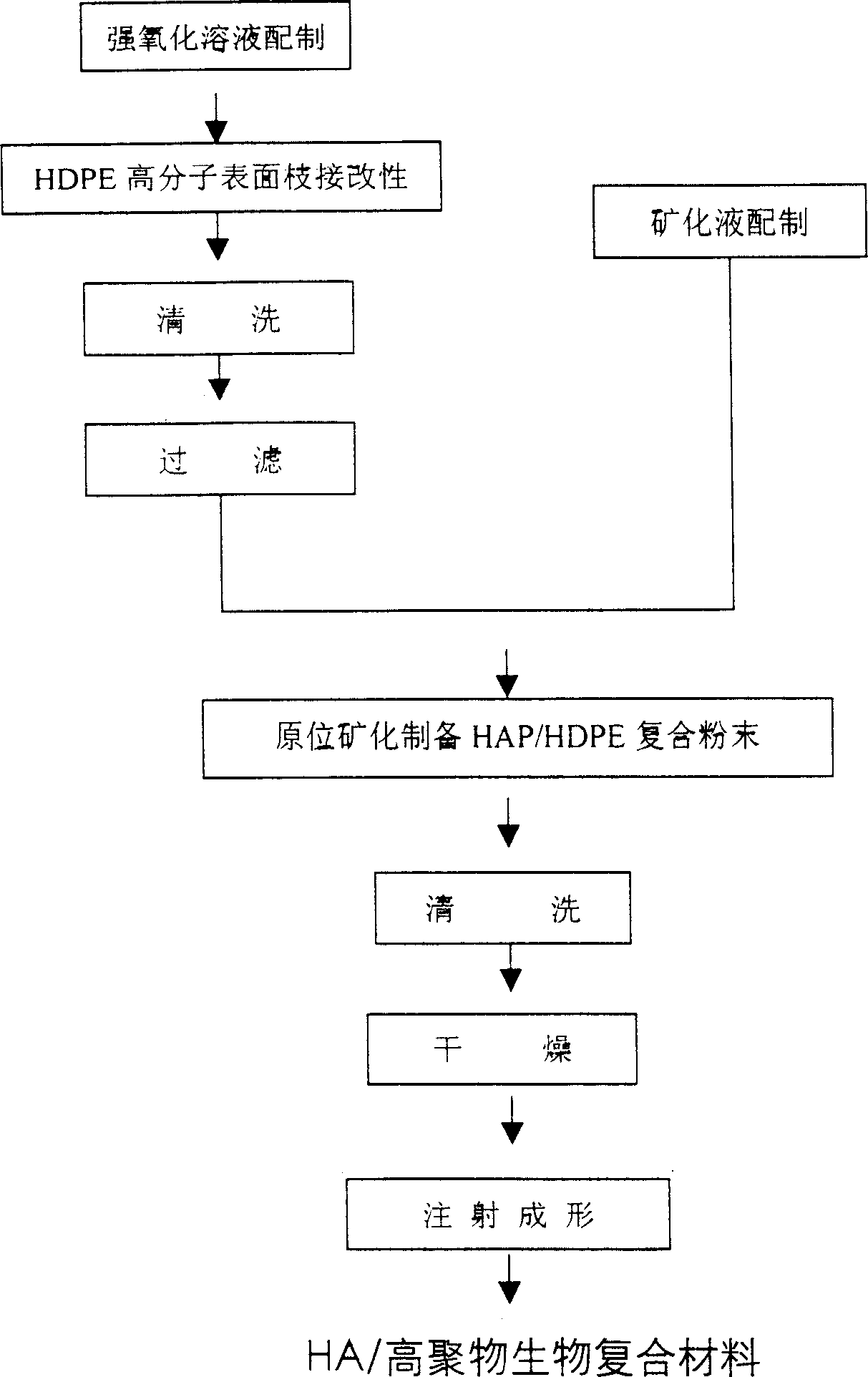

[0018] ① Mix benzoyl peroxide, acetone, and acrylic acid in a ratio of 5:24:40 mass percent to prepare a uniform strong oxidizing solution, immerse high-density polyethylene HDPE in the strong oxidizing solution, soak at 50°C for 2 hours, and make the high-density polyethylene A layer of peroxide layer is formed on the surface of ethylene HDPE, and benzoyl peroxide generates free radicals after being heated, triggering acrylic acid to graft onto the molecular chain of high-density polyethylene HDPE; cleaning, filtering, and drying;

[0019] ②Ca(NO 3 ) 2 4H 2 O, NaCl, (NH 4 )H 2 PO 4 and NaHCO 3 Dissolve in deionized water in turn to form a mineralization solution, control the temperature at 37°C, Ca / P=1.67, [Ca 2+ ]=4mmol / L, pH=7.4 or so, solution ionic strength l=0.15mol / L, immerse high-density polyethylene HDPE in the mineralization solution and mineralize for 3 days, filter, wash and dry to obtain HA / HDPE composite powder;

[0020] ③The HA / HDPE biocomposite was prepa...

Embodiment 2

[0022] ① Mix chromic acid, potassium permanganate, hydrogen peroxide and methyl methacrylate at a mass percentage of 5:8:50:100 to make a uniform strong oxidizing solution, immerse high-density polyethylene HDPE in it, and soak for 2 hours at room temperature. Make methyl methacrylate grafted onto the molecular chain of high-density polyethylene HDPE;

[0023] ② KCl, MgCl 2 , CaCl 2 、Na 2 SO 4 、K 2 HPO 4 , NaHCO 3 , NaCl is dissolved in deionized water to form a uniform solution, in which the concentration of each substance is: KCl is 3mmol / L, MgCl 2 1.5mmol / L, CaCl 2 2.5mmol / L, Na 2 SO 4 0.5mmol / L, K 2 HPO 4 1mmol / L, NaHCO 3 4.2mmol / L, NaCl 2mmol / L, use 3-hydroxymethyl-aminomethane and HCl as a buffer solution to maintain pH = 7.4, temperature 37 ° C, immerse high-density polyethylene HDPE in the mineralization solution for 3 days , filtered, washed and dried to obtain HA / HDPE composite powder;

[0024] ③The HA / HDPE biocomposite was prepared by injection molding...

Embodiment 3

[0026] ① Mix benzophenone, acrylic acid, and acetone into a homogeneous solution, immerse high-density polyethylene HDPE in it, soak at 50°C for 24 hours, and then use ultraviolet light (UV) to radiate energy at 7×10 3 Under J radiation, acrylic acid is grafted onto the surface of high-density polyethylene HDPE, cleaned, filtered, and dried;

[0027] ②Ca(NO 3 ) 2 4H 2 O, NaCl, (NH 4 )H 2 PO 4 and NaHCO 3 Dissolve in deionized water in turn to form a mineralization solution, control the temperature at 37°C, Ca / P=1.67, [Ca 2+ ]=4mmol / L, pH=7.4 or so, solution ionic strength l=0.15mol / L, immerse high-density polyethylene HDPE in the mineralization solution and mineralize for 3 days, filter, wash and dry to obtain HA / HDPE composite powder;

[0028] ③The HA / HDPE biocomposite was prepared by injection molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com