Composite nano carbon-base film electrode and use therefor

A nano-carbon-based thin-film and composite thin-film technology, applied in fixed capacitor electrodes, fixed capacitor parts, coatings, etc., can solve the problems of complicated carbon nanotube technology, not suitable for mass production, and difficult to guarantee repeatability, etc. Achieve excellent ion adsorption performance, reduce energy consumption, manufacture and use costs, simplify the structure and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

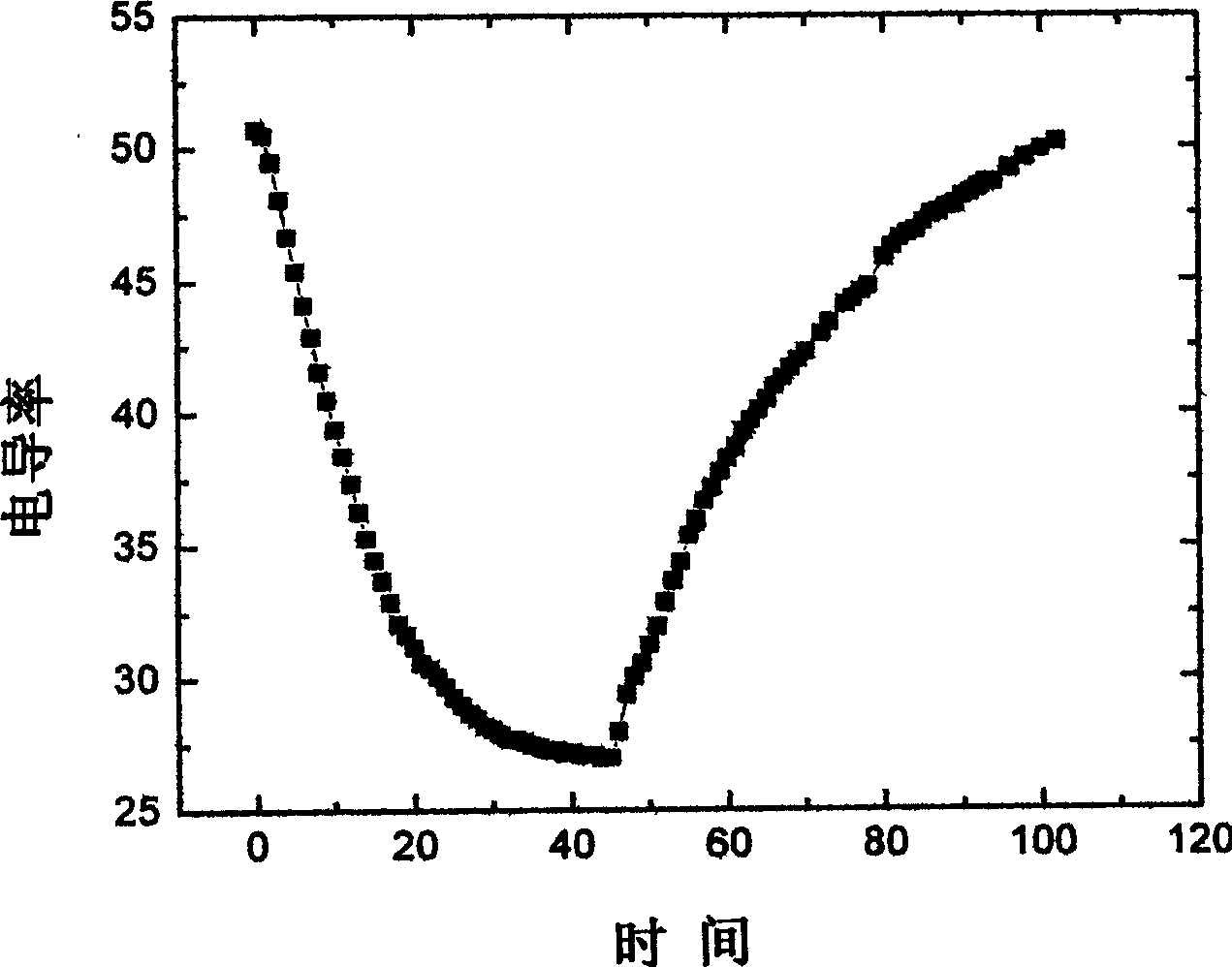

[0031]A capacitor unit is used, and the electrode is a carbon nanotube and fiber composite film grown on a Ni sheet with a diameter of 85 mm, and the number of electrodes used is 2. The solution to be treated was 30ml of NaCl solution with an initial conductivity of 50 μS / cm, and the NaCl solution was circulated by a constant flow pump. The applied voltage is U=1.2V. image 3 It is shown that with the increase of electrification time, the conductivity of the solution decreases, indicating that the capacitive device has a deionization effect on NaCl solution. After 45 minutes of electrification, the electrode was short-circuited and discharged, and the conductivity of the solution increased. After 100 minutes, the conductivity returned to the initial value before electrification, indicating that the adsorbed ions were completely desorbed and the electrode was regenerated.

example 2

[0033] A capacitor unit is used, and the electrode is a carbon nanotube and fiber composite film grown on a Ni sheet with a diameter of 85 mm, and the number of electrodes used is 2. The solution to be treated was 30ml of NaCl solution with an initial conductivity of 50 μS / cm, and the NaCl solution was circulated by a constant flow pump. Power on for a period of t1=15 minutes at U=1.2V, then short circuit, when the conductivity is close to the initial value before power on, power on again for a period of t2=20 minutes, then short circuit, the conductivity still returns to the initial value before power on. Figure 4 The change of the conductivity of the solution with the increase of electrification time is given. From Figure 4 It is obvious that the nano-carbon-based thin film electrodes used in the present invention can be reused.

example 3

[0035] A capacitor unit is used, and the electrode is a carbon nanotube and fiber composite film grown on a Ni sheet with a diameter of 85 mm, and the number of electrodes used is 2. The solution to be treated was 30ml of NaCl solution with an initial conductivity of 50 μS / cm, and the NaCl solution was circulated by a constant flow pump. Under different voltages U=0.4V, 0.6V, 0.8V, 1.0V, 1.2V, 2.0V, the same time t=20 minutes. Figure 5 The decrease trend of the conductivity of the solution is given with the increase of electrification time. It can be seen that within the applied voltage range, as the voltage increases, the capacitive deionization efficiency increases. When U=2.0V, the capacitive deionization efficiency reaches 50%, and when U=1.2V, the capacitive deionization efficiency also reaches 40%. When U=2.0V, no water decomposition was observed. The theoretical decomposition voltage of water is 1.23V. Considering the voltage drop caused by the impedance inside the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com