Anti-static layered board and preparation method thereof

A composite board, antistatic technology, applied in chemical instruments and methods, other chemical processes, synthetic resin layered products, etc. Social and economic benefits, improved antistatic effect, and feasible process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, fatty acid polyoxyethylene ether is selected as the antistatic agent.

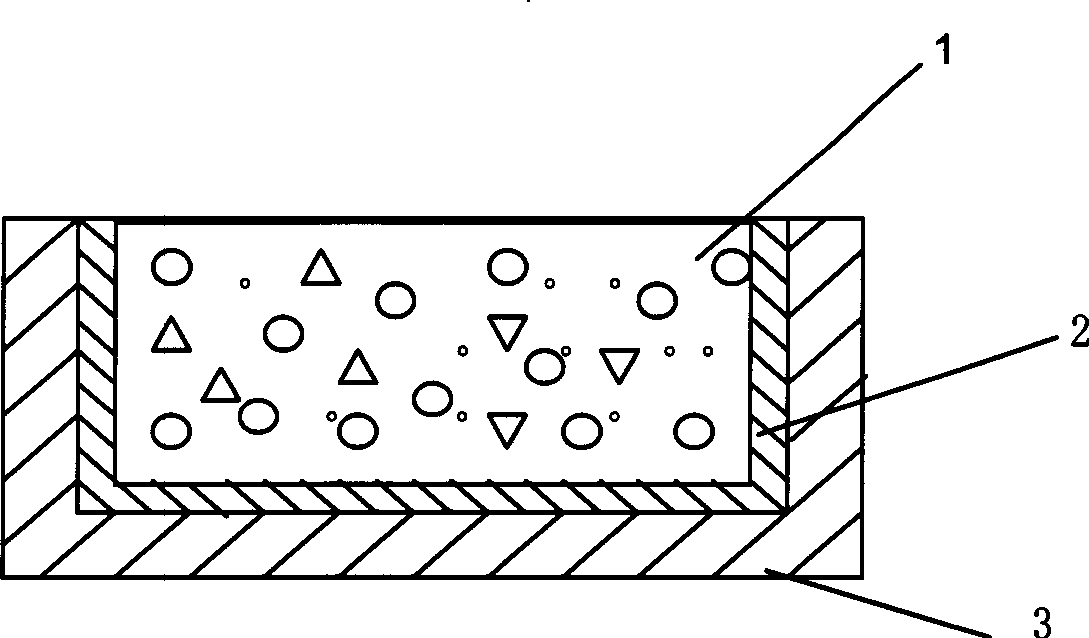

[0019] See attached figure 1 , to prepare a kind of antistatic composite board with hydraulic cementitious material as the base layer, polymer concrete as the transition layer, and polymer material as the cladding layer. The method is to mix the resin with the weight ratio of phenolic resin and epoxy resin 1:1, 400 mesh talcum powder, carbon black, ammonium polyphosphate, glass fiber, hexabromocyclododecane, fatty acid polyoxyethylene ether are mixed according to the weight ratio of 100:120:1:30:1:10:3 and Stir evenly, then add diethylenetriamine, the amount of which accounts for 15% of the weight of the resin, stir evenly, pour into the mold, and naturally cure at room temperature for 20-40min, then cure at 90°C for 100min to prepare a polymer Material cladding [3] with a thickness of 3mm.

[0020] Mix the above mixed resin, diethylenetriamine and No. 425 Portland cement in a ...

Embodiment 2

[0024] The antistatic agent of this embodiment selects conductive carbon black, first conducts super-dispersion treatment on conductive carbon black, mixes 100 parts of conductive carbon black, 5 parts of hyperdispersant and petroleum ether into a paste, and pulverizes it in a cone mill at room temperature for 40 minutes , mix until uniform.

[0025] See attached figure 1 , to prepare an antistatic composite board with hydraulic cementitious material as the base layer, polymer concrete as the transition layer, and polymer material as the cladding layer. The method is to mix unsaturated resin and epoxy resin with a weight ratio of 1:1, 500 mesh kaolin, iron yellow, ammonium polyphosphate, polypropylene fiber, brominated epoxy resin, and conductive carbon black are mixed in a weight ratio of 100:100:1:40:1:20:3 and stirred evenly , then add the curing system as triethylamine, methyl ethyl ketone and cobalt naphthenate, the weight ratio is 1:1:1, and the amount accounts for 15% ...

Embodiment 3

[0030] In this embodiment, graphite is selected as the antistatic agent. Firstly, the graphite is subjected to hyperdispersion treatment, and 100 parts of graphite, 4 parts of hyperdispersant and petroleum ether are mixed into a paste, and pulverized in a cone mill at room temperature for 50 minutes, and mixed until uniform.

[0031] See attached figure 1 , to prepare a kind of antistatic composite board with hydraulic cementitious material as the base layer, polymer concrete as the transition layer, and polymer material as the cladding layer. The method is to use a mixed resin of phenolic resin and unsaturated resin, and its weight ratio 1:1, 400 mesh calcium carbonate, carbon black, magnesium hydroxide, polybutadiene diol, chlorinated paraffin-70, and graphite are mixed in a weight ratio of 100:120:1:30:5:15:3 Stir evenly, then add dimethylaniline and benzoyl peroxide, the weight ratio is 1:1, and the amount accounts for 10% of the resin weight ratio, stir evenly, pour into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com