High dielectric constant composition and its preparing method and use

A high dielectric constant, polymer technology, applied in the field of high dielectric constant polyquinone radical polymers or their derivatives-polymer composites, can solve the problem of poor dispersion, material breakdown, and reduce the use range of materials, etc. problem, to achieve the effect of easy processing and stable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

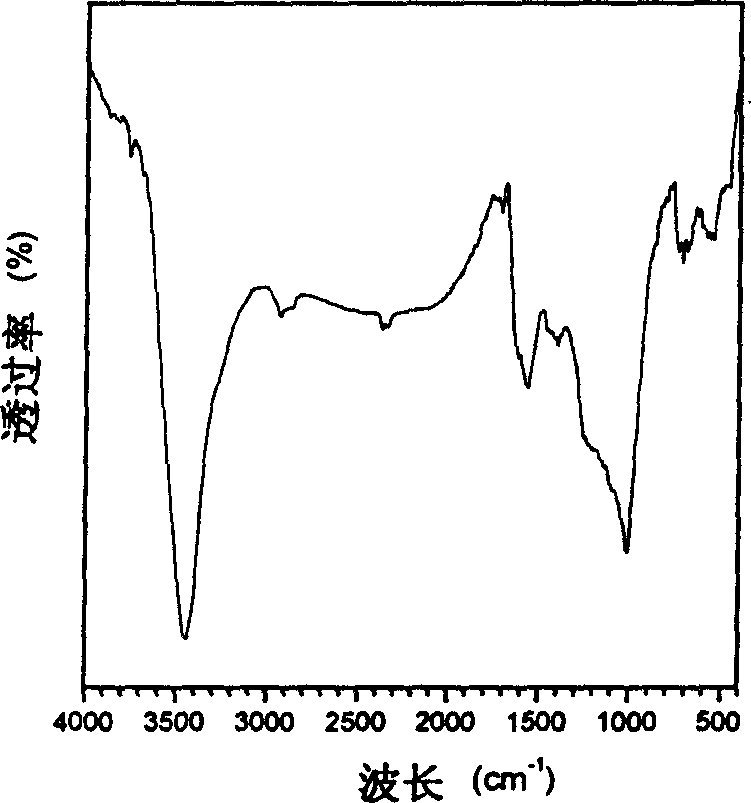

[0035] The synthesis of embodiment 1, polyoxyquinone radical polymer (PAQR)

[0036] Anthraquinone and pyromellitic anhydride (molar ratio 1:1), appropriate amount of zinc chloride (molar ratio to monomer 1:1) are mixed and ground evenly, put into heat-resistant glassware, wrap evenly with aluminum foil, put Put into a heating furnace and react at 300°C for 48 hours. The resulting solid was wrapped with filter paper and placed into a Soxhlet extractor, and extracted with dilute hydrochloric acid, ethanol, and xylene for 24 hours to remove unreacted reactants and catalysts. The dried product was taken out. Its infrared spectrum is shown in Figure 1a .

Embodiment 2

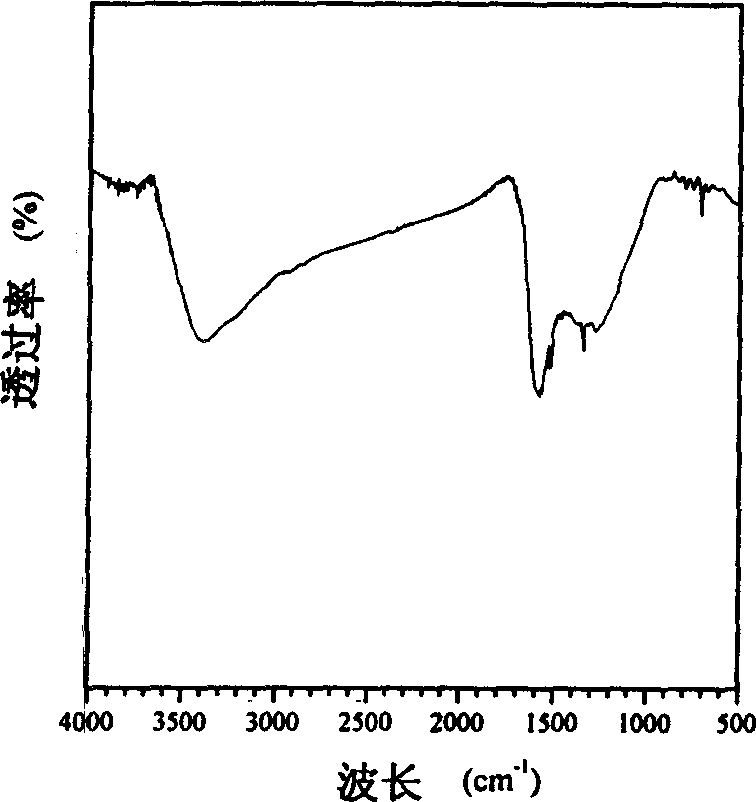

[0037] Embodiment 2, the synthesis of hydroxylated quinone radical polymer (abbreviated HO-PAQR)

[0038] The anthraquinone in Example 1 was changed to 1, 8-dihydroxyanthraquinone, and the rest of the steps were the same as in Example 1, and finally a hydroxylated polyoxyquinone free radical polymer was obtained. Its infrared spectrum is shown in Figure 1b .

Embodiment 3

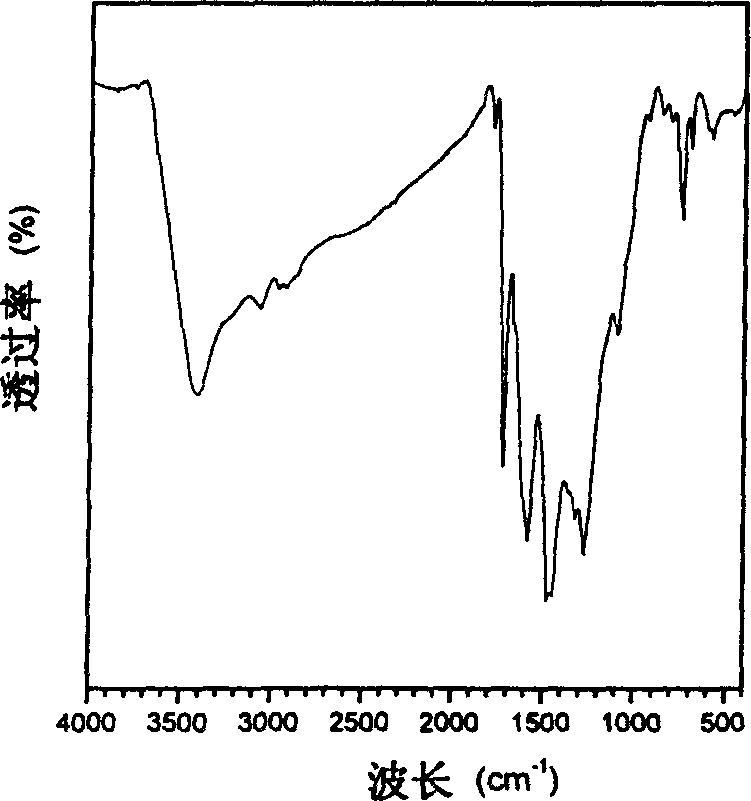

[0039] Embodiment 3, the synthesis of methoxy polyoxyquinone free radical polymer

[0040] A blend of 1,4-dimethoxyanthraquinone and pyromellitic anhydride (molar ratio 1:1), an appropriate amount of anhydrous aluminum trichloride (molar ratio to monomer 1:2) was dissolved in nitro Benzene solvent (mass concentration 5%), put into four-necked bottle. Install a reflux condenser and pass nitrogen gas, first mechanically stir for about 4 hours to dissolve the mixture, and then reflux at 210°C for 48 hours until no HCl gas is released. The excess nitrobenzene was distilled off under reduced pressure and the solid in the flask was transferred out, the remaining nitrobenzene was washed away with methanol, filtered with suction and dried in the air. Wrap the dried solid with filter paper and put it into a Soxhlet extractor, extract it with dilute hydrochloric acid, ethanol, xylene, and methanol for 24 hours to remove unreacted aluminum trichloride and reactants, and take out the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com