Use of catalyst for high temperature proton exchange membrane fuel cell

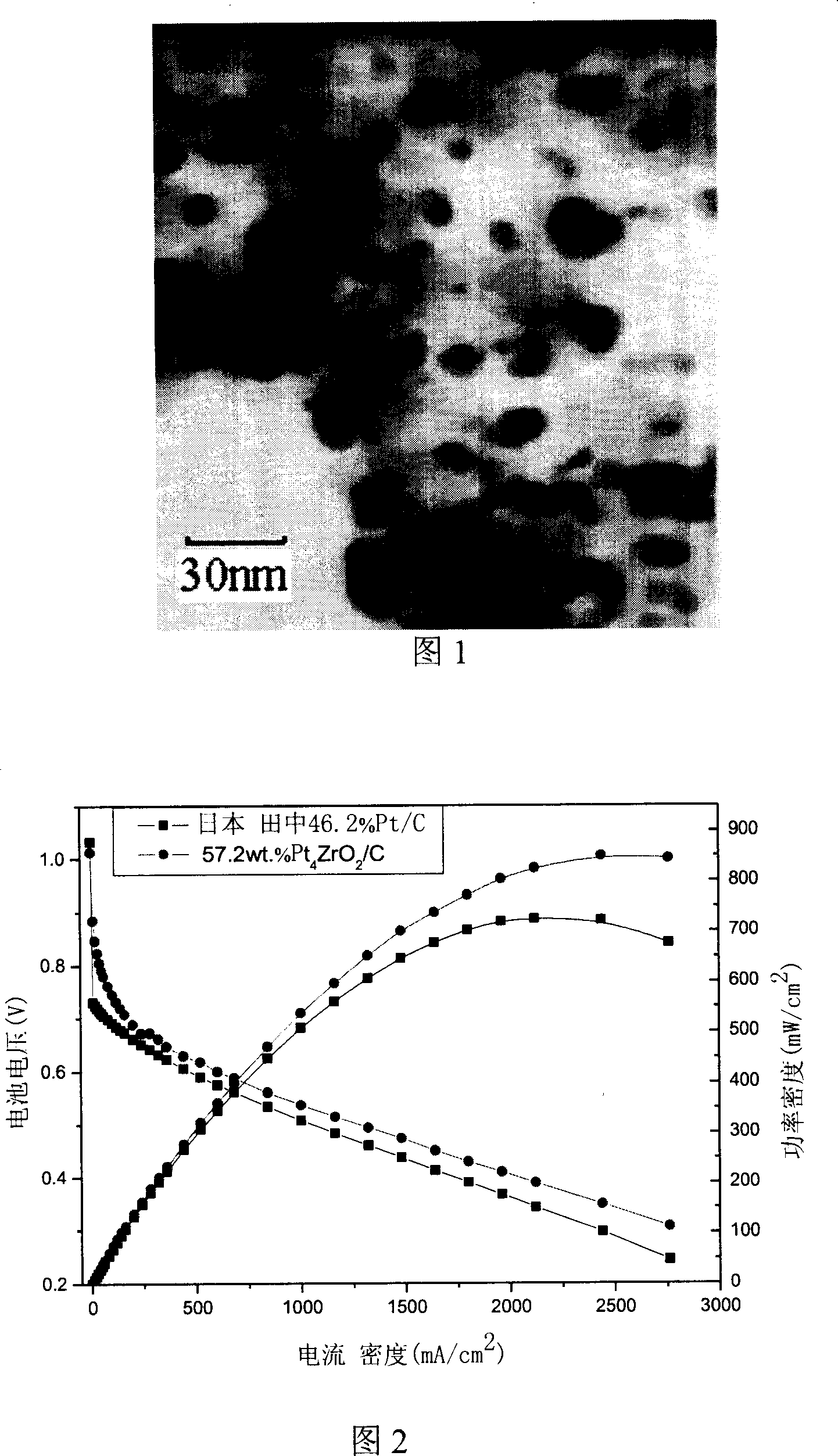

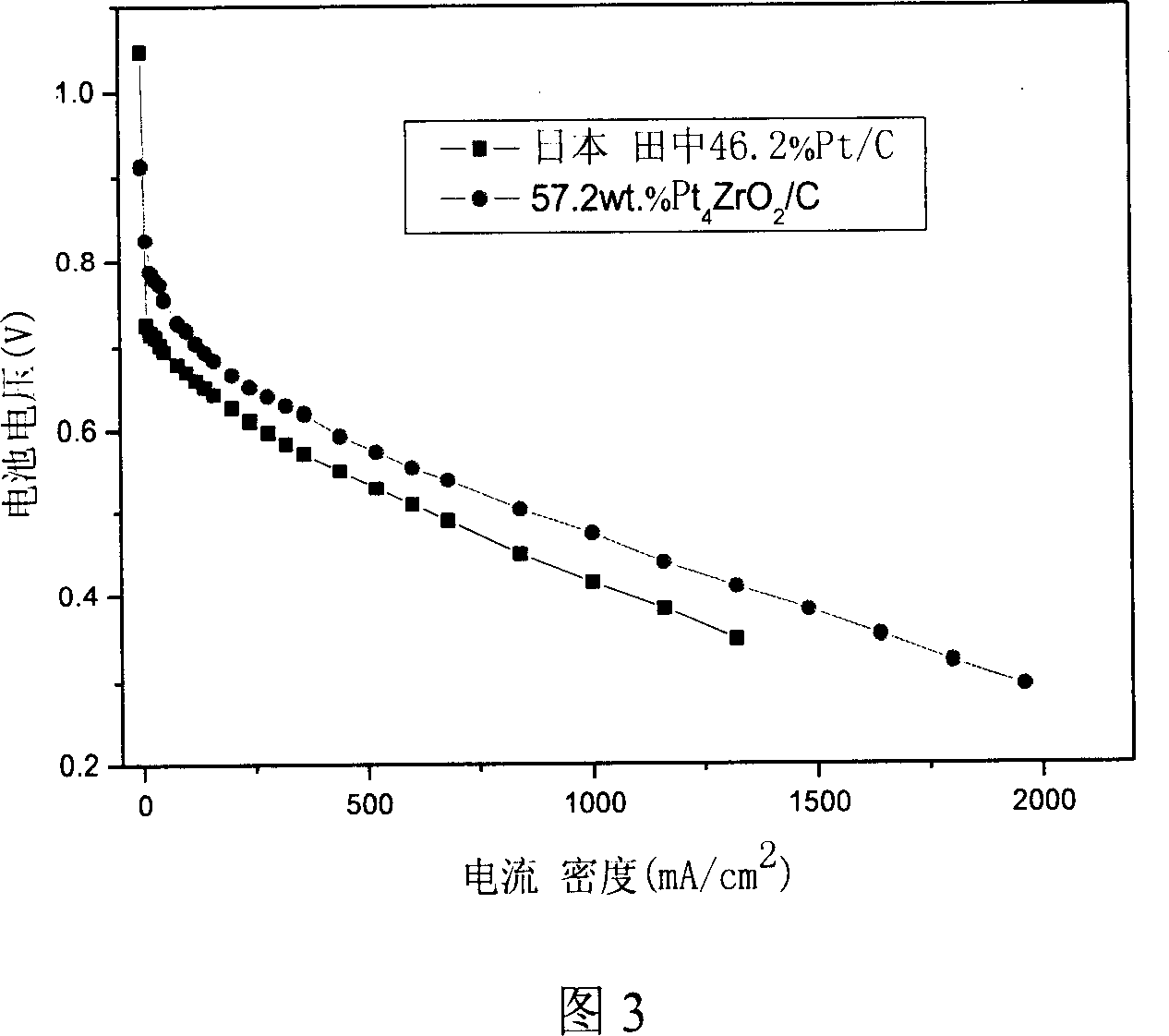

A technology of proton exchange membrane and fuel cell, which is applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc., and can solve the problem of not too high metal primary loading, uneven particle size distribution, large catalyst particle size, etc. problem, to achieve the effect of short cycle, uniform particle size and composition distribution, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 0.5g XC-72 carbon powder into 50ml 95% vol. of ethylene glycol aqueous solution, and mix evenly by ultrasonic to obtain slurry A; add 8.07ml chloroplatinic acid hexahydrate ethylene glycol solution with a concentration of 74mgPt / ml, 3. Mix 49ml of zirconyl nitrate dihydrate aqueous solution with a concentration of 20mgZr / ml, and mix them uniformly by ultrasonic to obtain mixed solution B; mix the above slurry A with solution B, and add 2.5M NaOH ethylene glycol solution under stirring conditions until PH=12 , put the above mixture in a microwave oven (frequency 2450 MHz, output power 700 W) and heat for 5 min, cool to room temperature, add 3M hydrochloric acid aqueous solution to pH = 4.5, and stir for 3 h in an oil bath at 60 °C. Wash with water and filter to neutral and Cl-free - , after drying, pass through 10% H 2 / N 2 Mixed air flow, heat treatment at 550°C for 4 hours, N 2 Purged to room temperature, the total metal content obtained was 57.2%, and the molar...

Embodiment 2

[0037] Add 0.5g XC-72 carbon powder into 50ml 95% vol. of ethylene glycol aqueous solution, and mix evenly by ultrasonic to obtain slurry A; add 4.2ml chloroplatinic acid hexahydrate ethylene glycol solution with a concentration of 74mgPt / ml, 1. Mix 12ml of cerium nitrate hexahydrate aqueous solution with a concentration of 20mgCe / ml, and mix them uniformly by ultrasonic to obtain mixed solution B; mix the above slurry A with solution B, and add 1M NaOH ethylene glycol solution under stirring condition to PH=12, The above mixture was heated in a microwave oven (frequency 2450 MHz, output power 700 W) for 10 min, cooled to room temperature, added 3M hydrochloric acid aqueous solution until pH = 6, and stirred at room temperature for 3 h. Wash with water and ethanol and filter to neutral and Cl-free - , after drying, pass through 20% H 2 / N 2 Mixed air flow, heat treatment at 500°C for 3 hours, N 2 Sweep to room temperature, obtain total metal content and be 40%, the catalyst...

Embodiment 3

[0039] Add 0.5g of carbon microspheres into 100ml of ethanol, and mix them uniformly by ultrasonic to obtain slurry A; add 1.55ml of chloroplatinic acid hexahydrate ethylene glycol solution with a concentration of 74mgPt / ml, and 0.5ml of vanadic acid with a concentration of 20mgV / ml Sodium dodecahydrate aqueous solution was mixed, and ultrasonically mixed evenly to obtain mixed solution B; the above slurry A was mixed with solution B, and 2.5M NaOH aqueous solution was added under stirring conditions to pH = 13, and the above mixed solution was placed in a microwave oven (frequency (2450MHz, output power: 700W) heated for 15min, cooled to room temperature, added 3M hydrochloric acid aqueous solution to pH = 0.5, and settled at room temperature for 3h. Wash with water and filter to neutral and Cl-free - , after drying, pass through 10% H 2 / Ar 2 Mixed air flow, heat treatment at 900°C for 2 hours, Ar 2 Purging to room temperature, the total metal content obtained is 20%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com