Dehydroxylation and purification of calcium fluoride materials using a halogen containing plasma

a technology of halogen containing plasma and calcium fluoride, which is applied in the direction of polycrystalline material growth, chemistry apparatus and processes, crystal growth process, etc., can solve the problems of low economic manufacturability, affecting the and reducing the burden on the demands for improved performance of computers and other electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

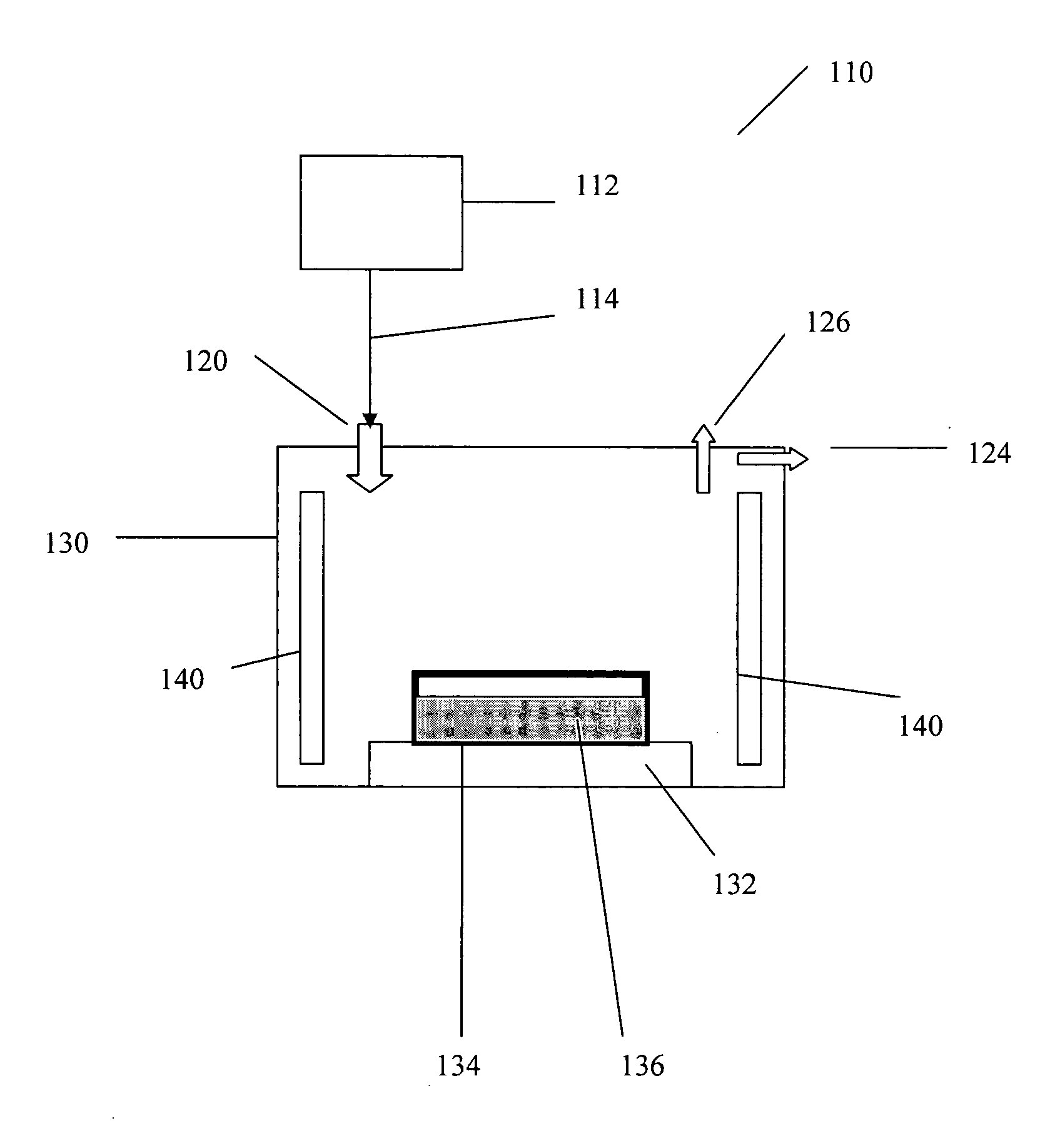

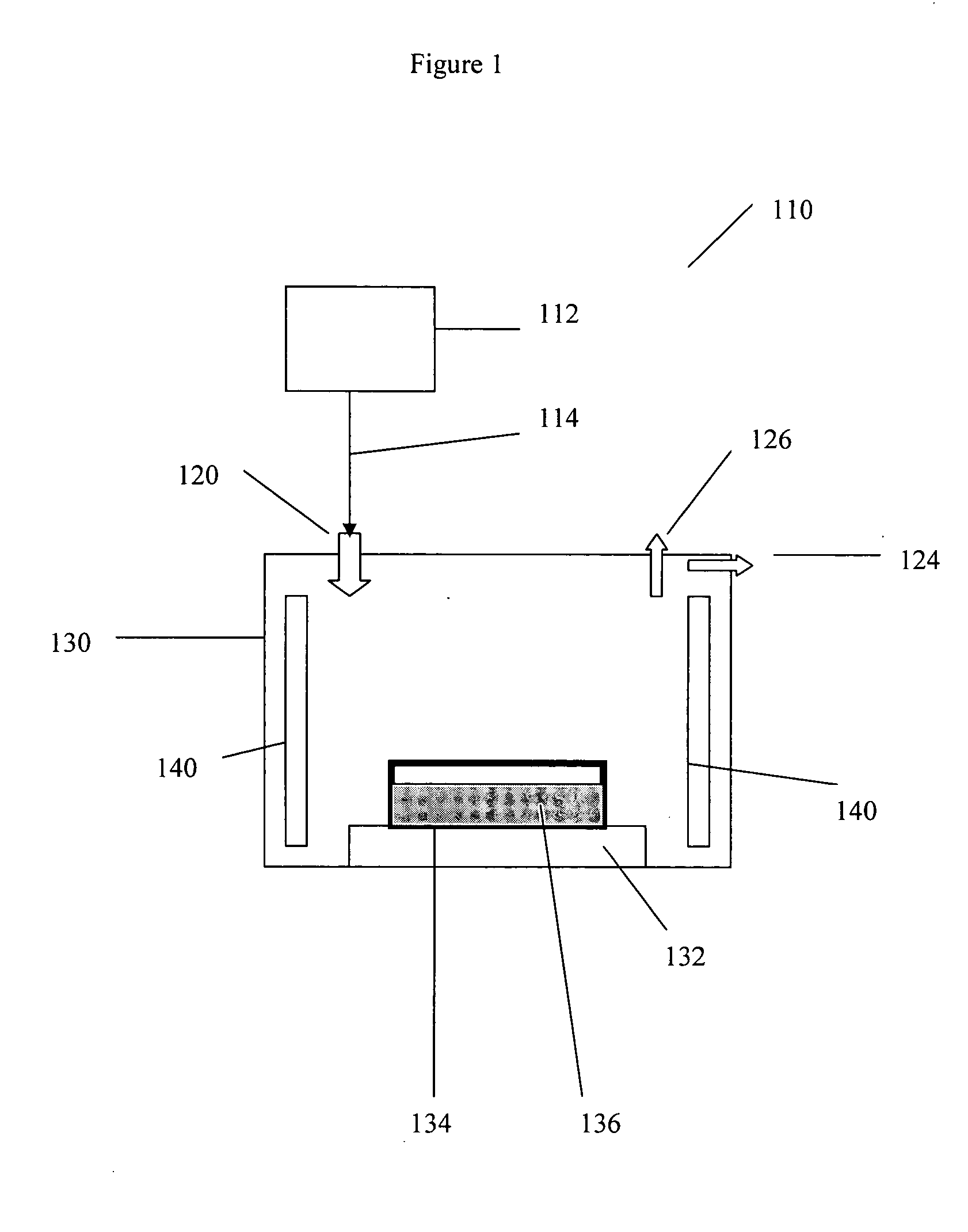

[0052] Referring to FIG. 1, the Figure illustrates a system 110 for treating a metal fluoride raw material having a plasma generator 112 having a source of a halogen or halogen-containing gas (not illustrated) and an exit port 116 (not illustrated) with connector 114 for transfer of the plasma formed by generator 112 to a furnace 130. The furnace 130 has a inlet port 120 for receiving the plasma, an outlet port 126, a port 124 for applying vacuum, heaters 140, a support 132 for one or a plurality of crucibles 134 (broad black lines, one crucible illustrated) or other vessel containing a metal fluoride powder 136, and other accessories such as temperature and pressure controllers, temperature probes or thermocouples that are not illustrated. The crucible 134 containing the metal fluoride material is placed on the support stand 132 and the furnace is evacuated to a pressure of less than 10−3 mm Hg to outgas the fluoride material, and in particular to remove oxygen and any easily remov...

example 2

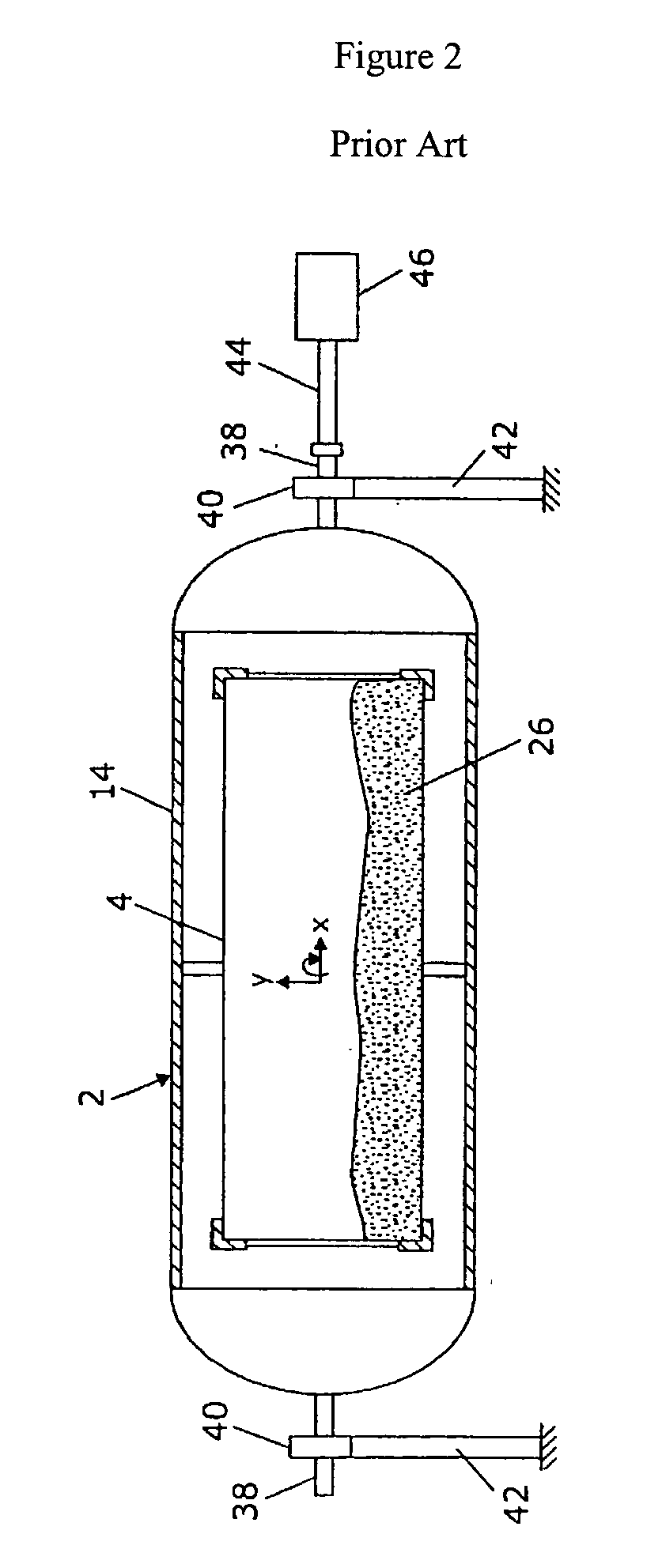

[0056] In this Example one uses a rotating vessel as illustrated in FIG. 2 which has been disclosed in U.S. Patent Application Publication 2003 / 0070606, published Apr. 17, 2003 and commonly owned along with the present application by Corning Incorporated to prepare a metal fluoride raw material for use in growing single crystals. As used in the present invention, the reaction vessel 14 has shaft ends 38 supported by bearings 40. The bearing 40 are attached to support frames 42. One side of the shafts 38 is coupled to a drive shaft 44 that is connected to a drive system 46, e.g., drive motor and gear train. The drive system 46 can be operated to rotate both the reaction vessel 14 and the reaction chamber 4. Rotary / flexible couplings (not shown) can be used to couple inlet port 16 to plasma 32 or a gas 20 source and to couple outlet port 18 to a treatment chamber 22 for treating substances exiting the vessel. During treatment with a halogen containing plasma the reaction chamber 4 is ...

example 3

[0058]FIGS. 3A and 3B illustrate in a simplified manner an embodiment of the invention in which a crucible containing a metal fluoride raw material is placed in a crystals growth furnace, treated with plasma and then used to grow a metal fluoride single crystal. This use of this procedure avoids the re-contaminating the plasma-treated metal fluoride material during transfer from a treatment furnace to a growth furnace.

[0059] In FIG. 3A a plasma generator 440 is connected to furnace 400 via connector 442. Furnace 400 has heaters 410 and 411 that can be controlled that are separately controlled, baffles 412 that divide the furnace into two upper and lower zones, element 450 connected to the furnace via a connector for the application of vacuum, and element 452 that is connected to the furnace for the admission of selected gases, for example, inert gases such as nitrogen, helium and argon; fluorinating gases such as CF4, F2, XeF2, C2F4Cl2, cyclo-C4F8 and other fluorinating gases known...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com