Curable polycyclic compounds and process for the production thereof

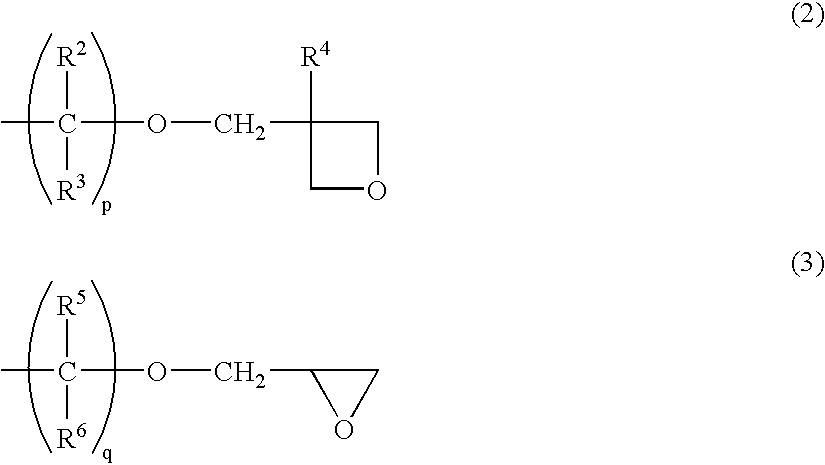

a polycyclic compound and polycyclic compound technology, applied in the field of cureable polycyclic compounds, can solve the problems of limited application and limited knowledge of cureable compounds, and achieve the effects of improving heat resistance and light resistance, reducing shrinkage, and improving optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of 1,3-bis[(3-ethyloxetan-3-yl)methoxy]adamantane

[0128] 300 ml of dehydrated tetrahydrofuran containing 16.8 g (0.1 mol) of 1,3-adamantanediol and 5.3 g (0.22 mol) of sodium hydride was stirred in a nitrogen atmosphere at the reflux temperature for 2 hours. Thereto was dropwise added 56.4 g (0.22 mol) of 3-ethyl-3-p-toluenesulfonyloxymethyloxetane. 36.5 g (0.22 mol) of potassium iodide was added. The resulting mixture was stirred at the reflux temperature for 12 hours. To the reaction mixture was added 200 ml of chloroform. The mixture was washed with water, and the chloroform layer was dried with magnesium sulfate.

[0129] The dried chloroform layer was subjected to distillation under reduced pressure for solvent removal, whereby was obtained a white solid and oily matter. This was purified by silica gel column chromatography to obtain 2.39 g (yield: 7.1%) of a white solid and oily matter. This compound was subjected to MASS spectrometry, 1H-NMR spectrometry and elemental...

example 2

Synthesis of 2,5-bis[(3-ethyloxetan-3-yl)methoxy]norbornane

[0136] 300 ml of dehydrated tetrahydrofuran containing 12.8 g (0.1 mol) of 2,5-norbornanediol and 5.3 g (0.22 mol) of sodium hydride was stirred in a nitrogen atmosphere at the reflux temperature for 2 hours. Thereto was dropwise added 56.4 g (0.22 mol) of 3-ethyl-3-p-toluenesulfonyloxymethyloxetane. 36.5 g (0.22 mol) of potassium iodide was added. The resulting mixture was stirred at the reflux temperature for 12 hours. To the reaction mixture was added 200 ml of chloroform. The chloroform layer was washed with water and then dried with magnesium sulfate. The dried chloroform layer was subjected to distillation under reduced pressure for solvent removal, whereby was obtained a white solid and oily matter. This was purified by silica gel column chromatography to obtain 1.39 g (yield: 4.71%) of a white solid and oily matter. This compound was subjected to MASS spectrometry, 1H-NMR spectrometry and elemental analysis. From th...

example 3

Synthesis of 5,7-dimethyl-1,3-bis[(3-ethyloxetan-3-yl)methoxy]adamantane

[0143] An operation was conducted in the same manner as in Example 1 except that 16.8 g (0.10 mol) of 1,3-adamantanediol was replaced by 19.6 g (0.10 mol) of 5,7-dimethyl-1,3-adamantanediol, whereby was obtained 2.70 g (yield: 7.4%) of a white compound and oily matter. This compound was subjected to MASS spectrometry, 1H-NMR spectrometry and elemental analysis. From the results of the analyses, the compound was confirmed to be intended 5,7-dimethyl-1,3-bis[(3-ethyloxetan-3-yl)methoxy]adamantane. The results of analyses are shown below.

[0144] MASS (EI): molecular weight 364 (M+)

[0145]1H-NMR: δ 1.1-2.0 (m, 24H), 2.6-4.1 (m, 12H)

[0146] Elemental analysis: as C22H36O4

[0147] Calculated: C 72.49, H 9.95

[0148] Measured: C 72.87, H 9.88

[0149] The compound was measured for inorganic chlorine content by the method for determination of saponifiable chlorine, described in ISO 4583 and the method described in ISO 4573...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com