Combination treatment with strontium for the prophylaxis and/or treatment of cartilage and/or bone conditions

a technology of cartilage and strontium, applied in the field of combination treatment, can solve the problems of increased risk of cancer and cardiovascular disease, loss of bone at a rate faster than the accretion of bone, and net loss of bone, and achieve the effect of prophylaxis and/or treatment of cartilag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

General Method for Preparation of Crystalline Salts of Strontium by Precipitation from Dissolved Strontium Chloride and Dissolved Sodium Salts of the Appropriate Carboxylic Anions

[0178] In a glass-beaker of 100 mL volume, 5 g of the sodium salt of the carboxylic acid was dissolved in a small volume of water that was slightly heated at temperatures not greater than 30-50° C. The final volume was 25-50 mL. In another beaker 10 g of SrCl2 (SrCl2 hexahydrate, Sigma-Aldrich 43,966-5) was dissolved in 100 mL of water. This latter solution was slowly decanted into the first solution of the dissolved sodium salt. The transfer continued until an initial cloudiness was observed, which resulted in a total volume of 50-100 mL. The solution was allowed to rest at room temperature (22-24° C.) for several days until significant amounts of crystallized precipitate of the organic strontium salt appeared.

[0179] The reaction that proceeds is exemplified by the reaction between strontium ions and so...

example 2

General Method for Preparation of Crystalline Salts by Neutralisation of Carboxylic Acids with Strontium Hydroxide

[0183] A small amount of the organic acid proper (0.75-3 g, see table below) was dissolved in water by heating to temperatures between 30° C.-50° C. Then, strontium hydroxide (Sigma Aldrich, Sr (OH)2*8H2O, MW 265.71, CAS no. 311-10-0, approx. 10 g / L) was slowly added. Then, a magnetic stirring rod was added and the stirring and gentle heating (i.e. 30-50° C.) of the suspension was started. After some time, the solution clarifies and all the solid material dissolves. The heating is maintained, and after three hours of incubation, the solution is filtered while hot on a Büchner funnel. Very small amounts of impurities were left in the filter.

[0184] The filtrate was subsequently allowed to cool at room temperature overnight, which resulted in growth of fine-powdered crystals of the desired strontium salt. Further purifications of the salts can be performed by repeated re...

example 3

Determinations of Solubility of Organic Strontium Salts

Synthesis of Strontium Salts

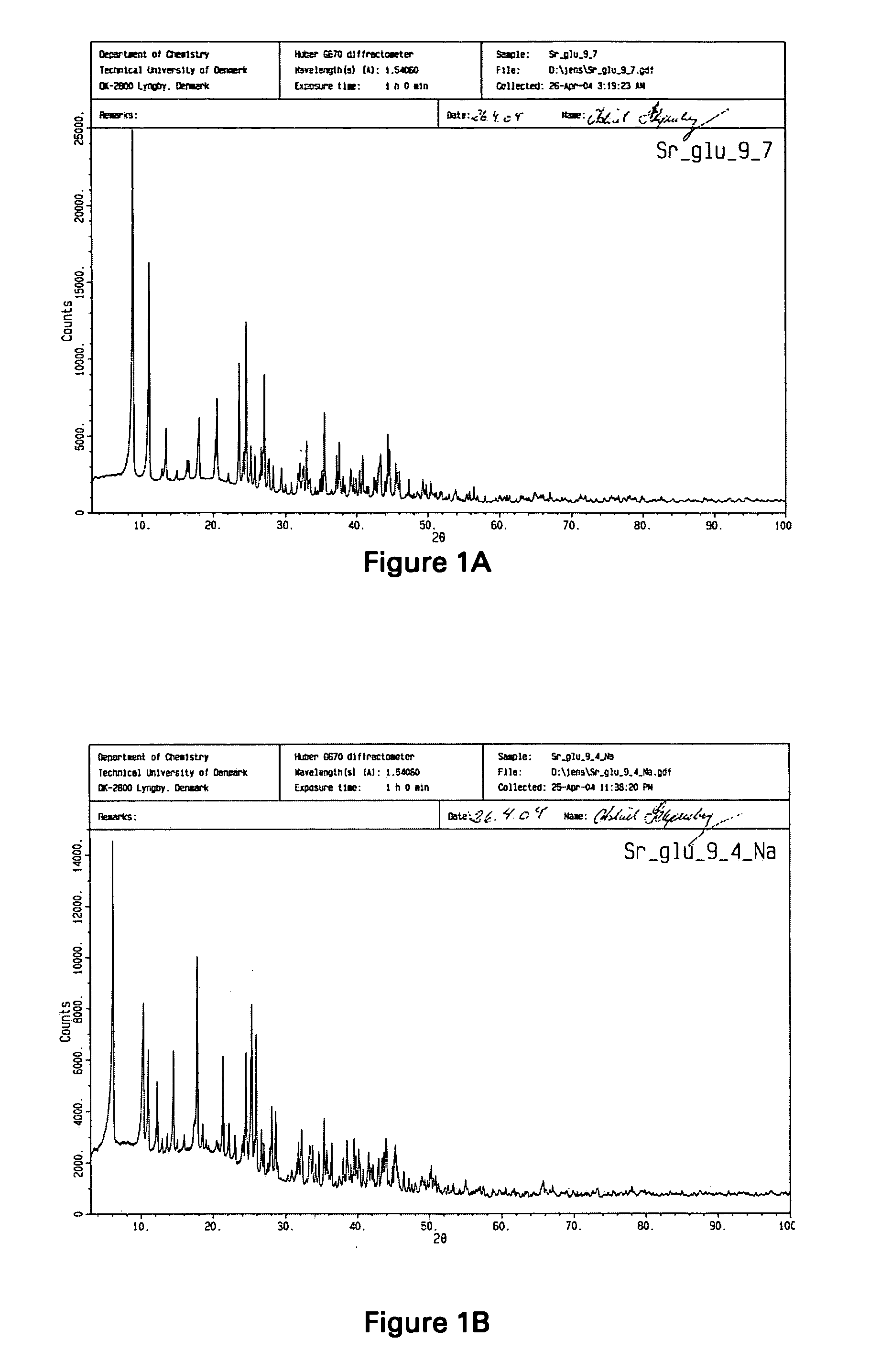

[0185] The great majority of strontium salts could be obtained by reacting the sodium salt of the organic acid with strontium chloride following the general synthesis method described in example A. However, strontium citrate, strontium tartrate, strontium succinate and strontium α-ketoglutarate for the solubility investigations was obtained by synthesis from the free acid forms of the carboxylic acid and strontium hydroxide as described in example 2. Strontium glutamate was obtained as described in example 4, using an incubation temperature of 100° C. and using strontium chloride and L-glutamic acid for the synthesis for obtaining pure and homogeneous hexahydrate crystals of strontium glutamate. As described in example 4 the strontium glutamate salt obtained by this method is distinct from a previously described form of crystalline strontium L-glutamate. Detailed investigations of solubility were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com