Method for preparnig spherical spinel Li-Mn-oxide lithium ion cell anode material

A lithium-ion battery, lithium manganese oxide technology, applied in the direction of lithium oxide;/hydroxide, electrode manufacturing, battery electrodes, etc., can solve the problems of positive electrode material capacity decay, prone to thermal decomposition, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

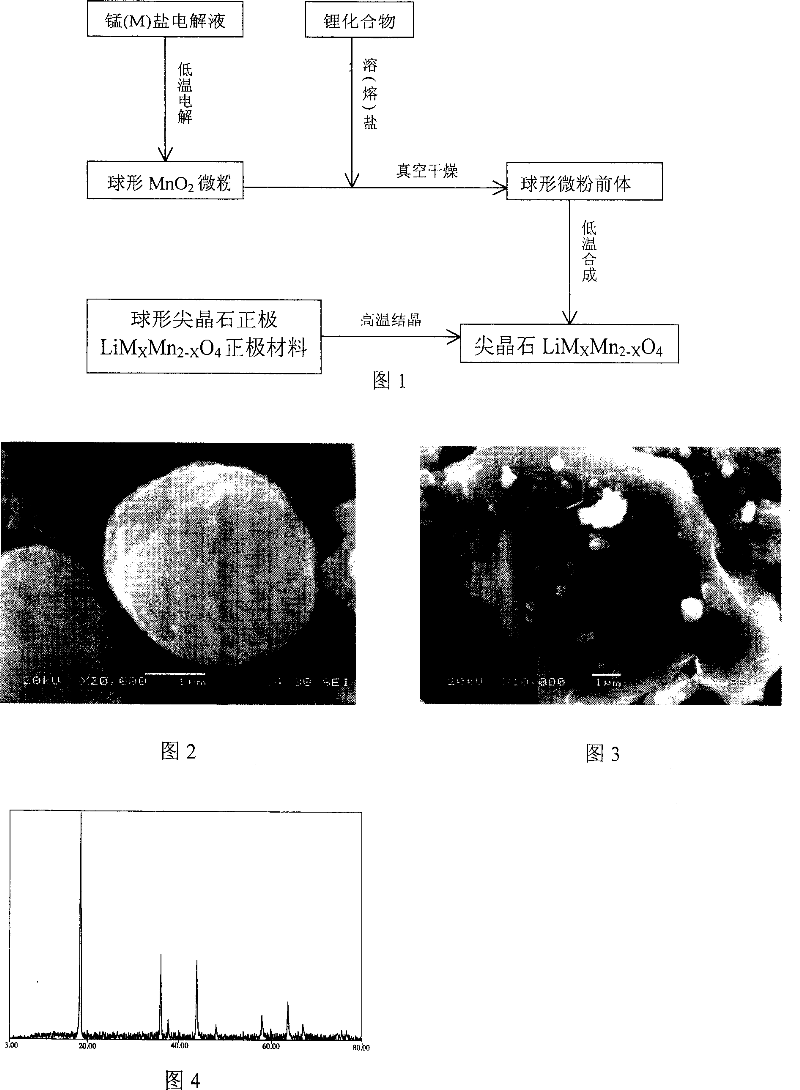

[0029] Example: spherical spinel cathode LiMn 2 o 4 Lithium-ion battery cathode material and its preparation

[0030] Referring to Fig. 1, pure MnSO was analyzed by 900mL of 1.5M 4 Add 100mL volume ratio concentration of 97% analytically pure H to the solution 2 SO 4 The solution constitutes the electrolyte, which is injected into the electrolytic cell with a circulating cooling pipe inside. The lead plate is used as the electrode, and the effective area of the anode is 150cm 2 , control the temperature of the electrolytic cell to 20°C, and the electrolytic current to 25A / cm 2 , low-temperature electrolytic preparation of spherical MnO 2 Microparticles; put the micropowder prepared in the previous step into 310°C lithium nitrate molten salt, cool the molten salt after heat preservation and diffusion for 3 hours, and then wash away the surface lithium nitrate with deionized water; the obtained wet micropowder was vacuum-dried at a temperature of 40°C, and the obtained D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com